Tetrakaidecahedron metal hydroxystannate and preparation method and application thereof

A technology of hydroxystannate and tetradecahedron, which is applied in the field of photocatalytic materials and can solve the problems that tetradecahedral hydroxystannate is rarely reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix equimolar tin chloride solution and calcium acetate solution, stir evenly, add ethylenediamine and sodium dihydrogen phosphate regulators, the molar ratio of the amount to tin salt is 1:1, stir for 20 min, Then a certain amount of NaOH solution was slowly added dropwise, the molar ratio of alkali to tin salt was 1:7, and transferred to a hydrothermal kettle to react for 15 hours at a reaction temperature of 100°C.

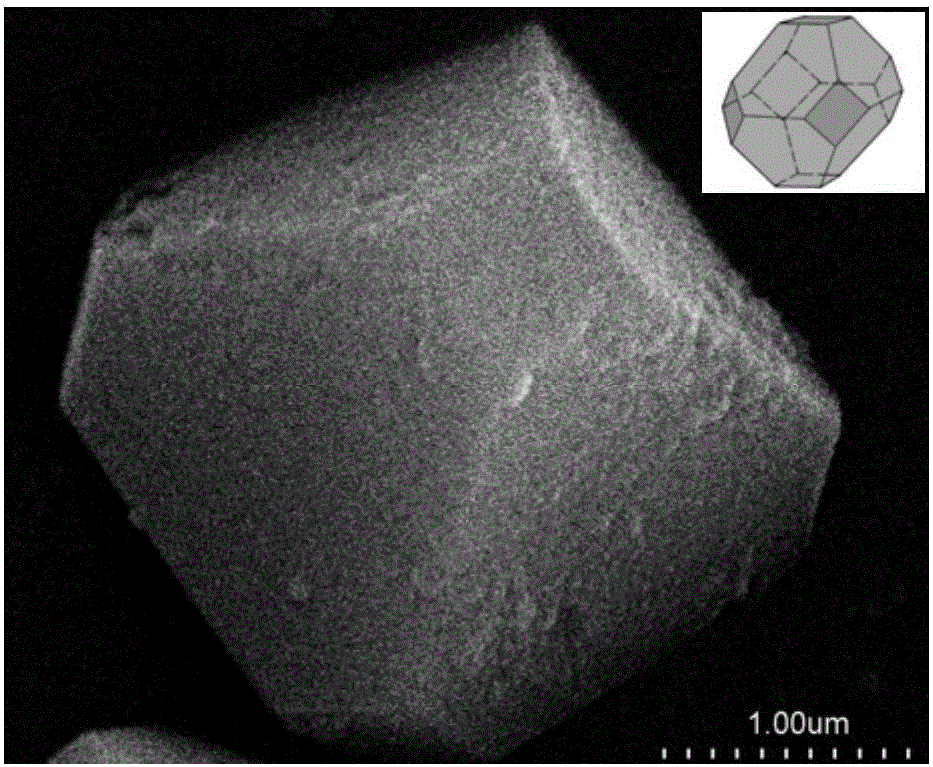

[0019] Such as figure 1 As shown, the obtained tetradecahedral calcium hydroxystannate has good morphology and regular scale.

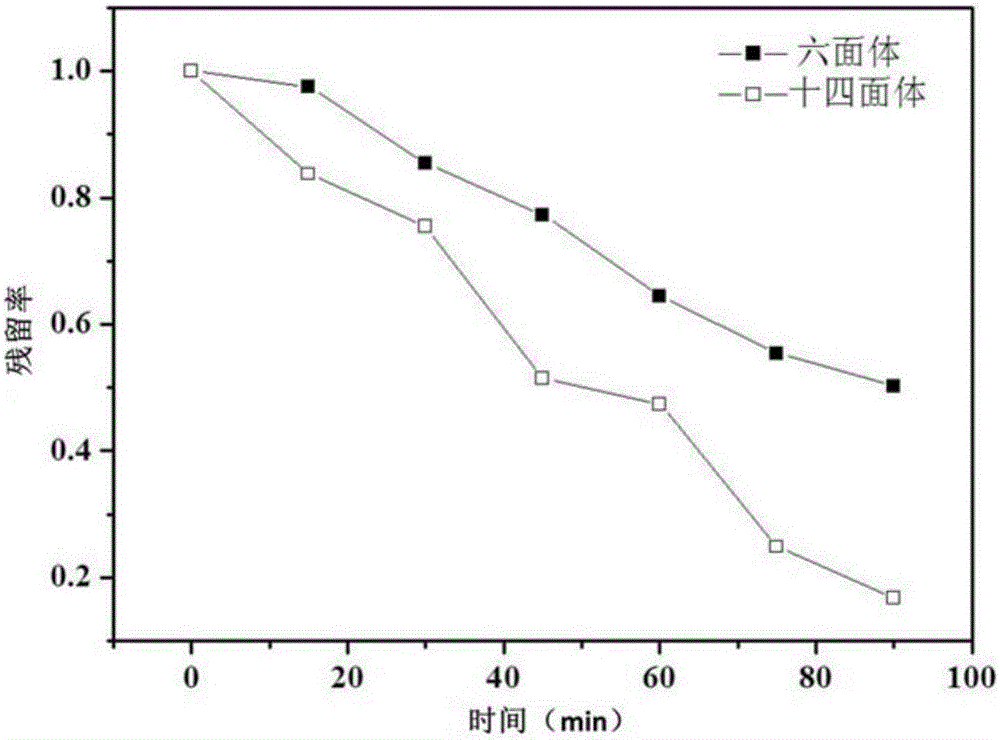

[0020] Tetradecahedral calcium hydroxystannate and hexahedral calcium hydroxystannate were used for photocatalytic degradation of methylene blue, such as figure 2 As shown, the photodegradation effect of tetradecahedron is better than that of hexahedron.

Embodiment 2

[0022] Mix equimolar tin chloride solution and cobalt acetate solution, stir evenly, add two regulators, triethanolamine and potassium phosphate, the molar ratio of the amount to tin salt is 1:2, stir for 60 min, then slowly drop Add a certain amount of NaOH solution, the molar ratio of alkali to tin salt is 1:6, and transfer to a hydrothermal kettle to react for 20h, and the reaction temperature is 90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com