A nanofiber high-magnification hydrophilic nonwoven material and its preparation method

A technology of non-woven materials and nanofibers, applied in the field of non-woven materials, can solve the problems of poor hydrophilicity and low hydrophilic ratio, and achieve the effects of preventing water loss, improving hydrophilic performance and improving hydrophilic ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

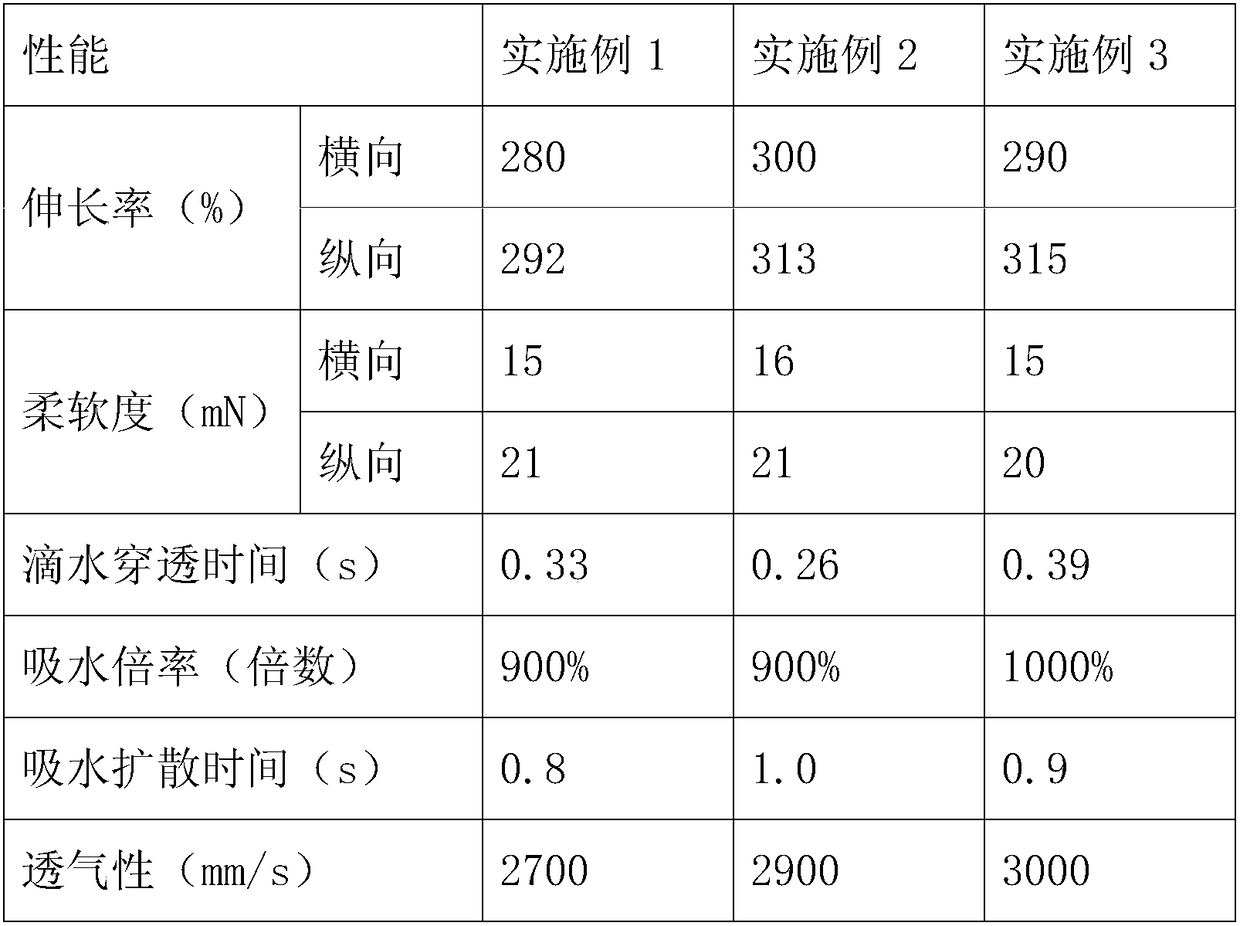

Embodiment 1

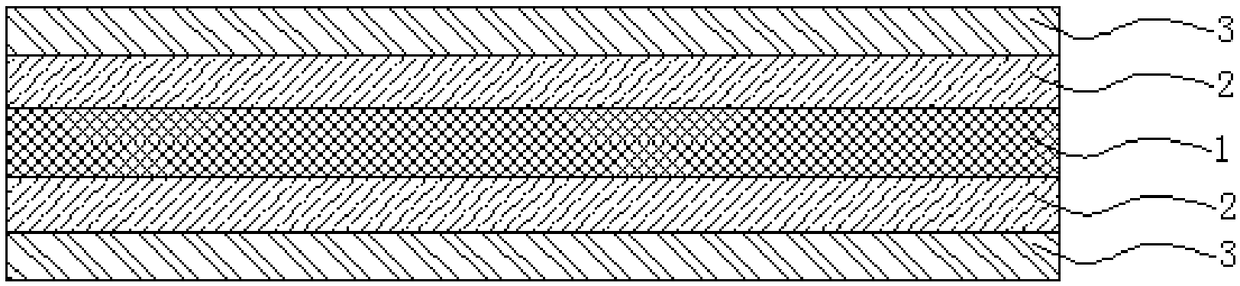

[0026] In this embodiment, the nanofiber high-magnification hydrophilic nonwoven material includes a nanofiber antibacterial layer 1, at least one side of the nanofiber antibacterial layer 1 is sequentially provided with a nanofiber water-retaining layer 2, a nanofiber hydrophilic layer 3, and a nanofiber antibacterial layer. The fiber antibacterial layer 1 is a nano-polypropylene fiber antibacterial layer, the hydrophilic ratio of the nanofiber high-magnification hydrophilic nonwoven material is 1000%, and the nanofiber water-retaining layer 2 is selected from the nano-modified polymer fiber layer;

[0027] The nanofiber hydrophilic layer 3 is a modified polypropylene fiber hydrophilic layer, the thickness of the nanofiber water-retaining layer 2 is 40 μm, and the preparation process of the modified polypropylene fiber hydrophilic layer is as follows: polypropylene is prepared into polypropylene fiber after melt spinning fiber, coating the hydrophilic solution on the polypropy...

Embodiment 2

[0031] The nanofiber high-magnification hydrophilic nonwoven material in this embodiment includes a nanofiber antibacterial layer 1, at least one side of the nanofiber antibacterial layer 1 is sequentially provided with a nanofiber water-retaining layer 2, a nanofiber hydrophilic layer 3, and a nanofiber antibacterial layer. The antibacterial layer 1 is a nano-polypropylene fiber antibacterial layer, the hydrophilic ratio of the nanofiber high-magnification hydrophilic nonwoven material is 900%, and the nanofiber water-retaining layer 2 is selected from the nano-modified polymer fiber layer;

[0032] The nanofiber hydrophilic layer 3 is a modified polypropylene fiber hydrophilic layer, the thickness of the nanofiber water-retaining layer 2 is 50 μm, and the preparation process of the modified polypropylene fiber hydrophilic layer is: polypropylene is prepared into polypropylene by melt spinning fiber, coating the hydrophilic solution on the polypropylene fiber, and drying to ob...

Embodiment 3

[0036] In this embodiment, the nanofiber high-magnification hydrophilic nonwoven material includes a nanofiber antibacterial layer 1, at least one side of the nanofiber antibacterial layer 1 is sequentially provided with a nanofiber water-retaining layer 2, a nanofiber hydrophilic layer 3, and a nanofiber antibacterial layer. The fiber antibacterial layer 1 is a nano-polypropylene fiber antibacterial layer, the hydrophilic ratio of the nanofiber high-magnification hydrophilic nonwoven material is 1000%, and the nanofiber water-retaining layer 2 is selected from the nano-modified polymer fiber layer;

[0037] The nanofiber hydrophilic layer 3 is a modified polypropylene fiber hydrophilic layer, the thickness of the nanofiber water-retaining layer 2 is 60 μm, and the preparation process of the modified polypropylene fiber hydrophilic layer is as follows: polypropylene is prepared into polypropylene fiber after melt spinning fiber, coating the hydrophilic solution on the polypropy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com