Preparation method for cylindrical composite grid structure

A technology of grid structure and composite material, applied in the field of composite material process manufacturing, can solve problems such as high cost, and achieve the effect of improving production efficiency and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

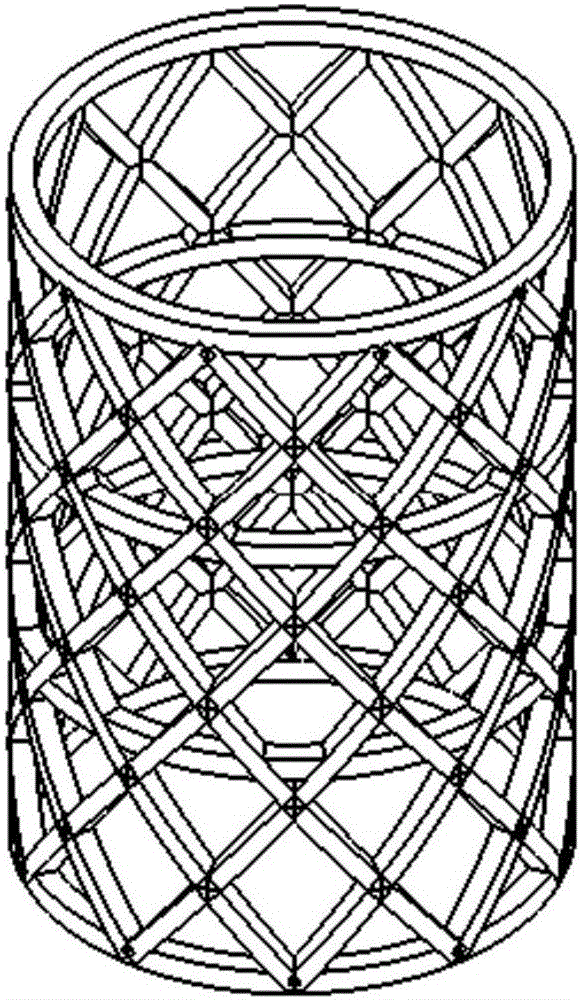

[0047] to attach figure 1 The structure is an example, only the grid structure without inner and outer skins, assuming that the formed grid structure product has an inner diameter of 138mm, a length of 600mm, and a thickness of 5mm. Implement with the following preparation method.

[0048] 1) Clean the mold: Wipe the surface of the mold with a rag dipped in acetone. After the acetone has evaporated, apply a thin and uniform layer of release agent on the surface of the mold, and dry the mold for 30 minutes before use;

[0049] 2) PET foam shaping: Use a cylindrical mold with a diameter of 133mm, select 10mm thick PET foam, cut the foam according to the size of the product (leaving enough margin), use a heat gun to soften the foam with hot air at 60°C to 100°C, and blow it Curl the foam with hot air until the foam curls into a cylindrical shape and wraps around the cylindrical mold. Cut the excess foam and tighten the heat-resistant film to fix it. Put it in an oven, keep it ...

Embodiment 2

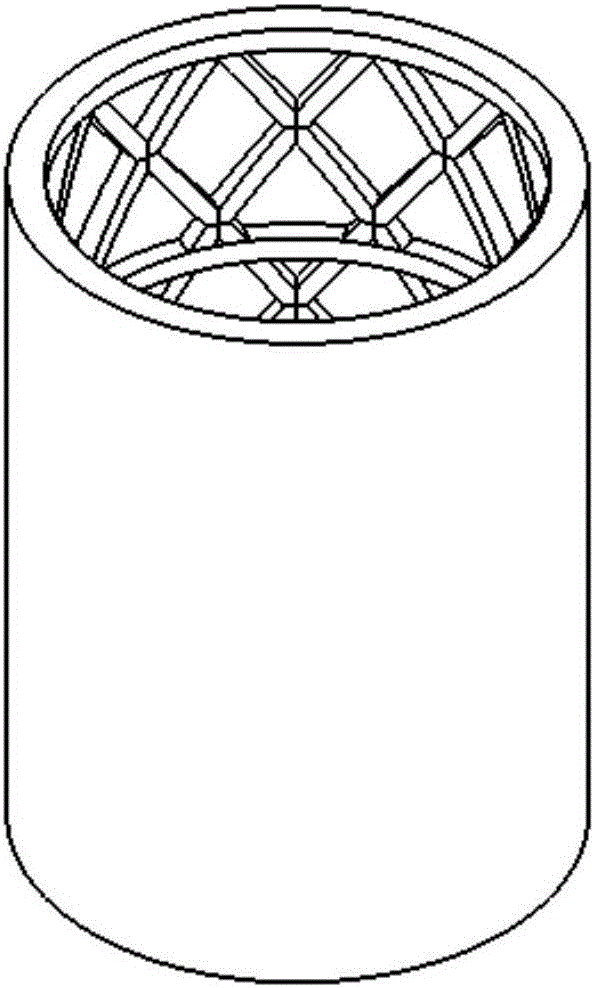

[0056] to attach figure 2 The structure is an example, including grid structure and outer skin, assuming that the formed grid structure product has an inner diameter of 138mm, a length of 600mm, and a grid rib thickness of 5mm. Adopt the following preparation method to carry out.

[0057] Step 1)-4) is identical with embodiment 1;

[0058] 5) Grid wet winding: add pin tooling rings at both ends of the mold, strictly arrange the relative and absolute positions of the pin rings according to the grid design line, seal the edges of the pin rings, and each pin must be wrapped with a release cloth , both ends of the foam are sealed with sealant, and the height of the sealant is lower than that of the foam. Compile the winding program according to the design line type. Adjust and control the temperature and humidity of the work site, configure resin, and wet-wind the mesh with a 5-axis high-precision winding machine;

[0059] 6) Wet winding of the outer skin: according to the meth...

Embodiment 3

[0063] to attach Figure 6 , 7 The structure is an example, including inner skin, grid sandwich structure and outer skin, assuming that the inner diameter of the molded grid structure product is 133mm, the inner skin is 5mm, the grid rib thickness is 5mm, the outer skin is 5mm thick, and the length is 600mm. Implement with the following preparation method.

[0064] 1) Clean the mold, wipe the surface of the mold with a rag dipped in acetone, after the acetone has evaporated, apply a thin and uniform layer of release agent on the surface of the mold, and let the mold dry for 30 minutes before use;

[0065] 2) Pre-forming of PET foam: Cut the foam according to the grid size (inner diameter, outer diameter, length) of the product (leave enough margin). Use a heat gun to soften the foam with hot air at 60°C to 100°C, and curl the foam while blowing the hot air until the foam is curled into a cylindrical shape and wrapped on a cylindrical mold. Cut the excess foam and tighten th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com