Normal-temperature 3D printing spray nozzle

A 3D printing and nozzle technology, applied in the direction of additive processing, etc., can solve the problems of unable to achieve normal temperature viscous liquid printing, unable to meet mass consumption, small application range, etc., to solve the problem of normal temperature slurry 3D printing, reasonable force , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention is described in detail as follows by specific example:

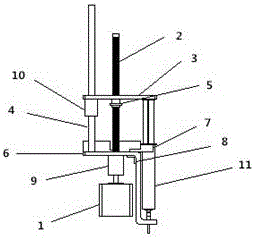

[0011] Such as figure 1 As shown, a normal temperature 3D printing nozzle includes a stepping motor 1, a screw 2, an upper mounting plate 3, a guide rod 4, a sleeve 5, a lower mounting plate 6, a connecting plate 7, a coupling 9, and a sliding bearing 10 , extruder syringe 11; the stepper motor 1 is connected to the lead screw 2 through a coupling 9, the sleeve 5 is fixed on the upper mounting plate 3 by threads, and is threadedly matched with the lead screw 2, so that the thread The bar 2 drives the upper mounting plate 3 to move up and down, the lower end of the guide rod 4 is fixed on the lower mounting plate 6, the sliding bearing 10 and the upper mounting plate 3 adopt an interference fit, and the guide rod 4 passes through the sliding bearing 10, so that The upper mounting plate 3 can slide up and down along the guide rod 4 , the extruder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com