A pop-up slider mechanism for an injection mold

An injection mold, pop-up technology, applied in the field of injection mold structure, can solve the problems of increasing the mold size, failure of fixed mold core-pulling slider, large volume of oil cylinder core-pulling mechanism, etc., to meet the requirements of appearance and movement process smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

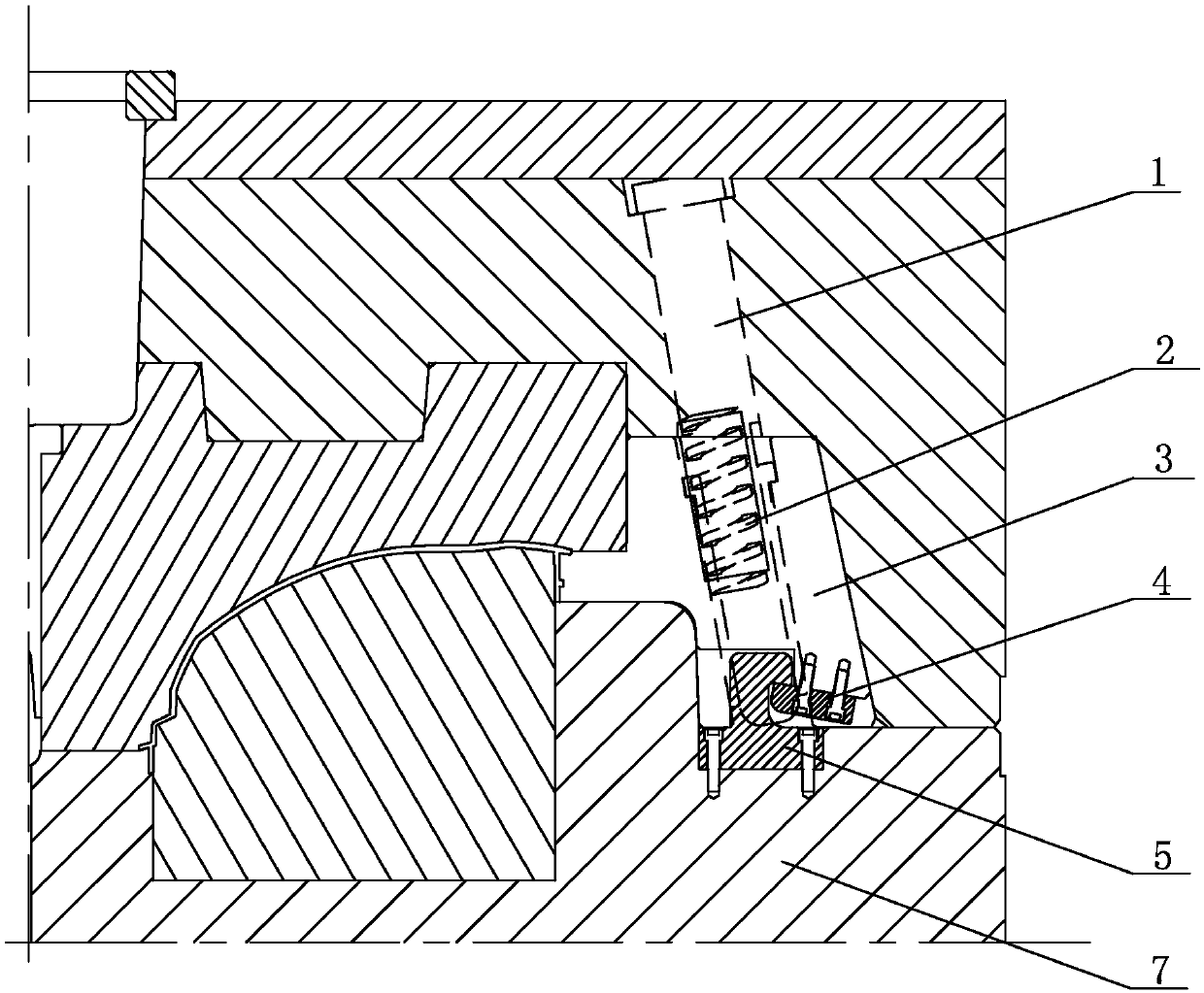

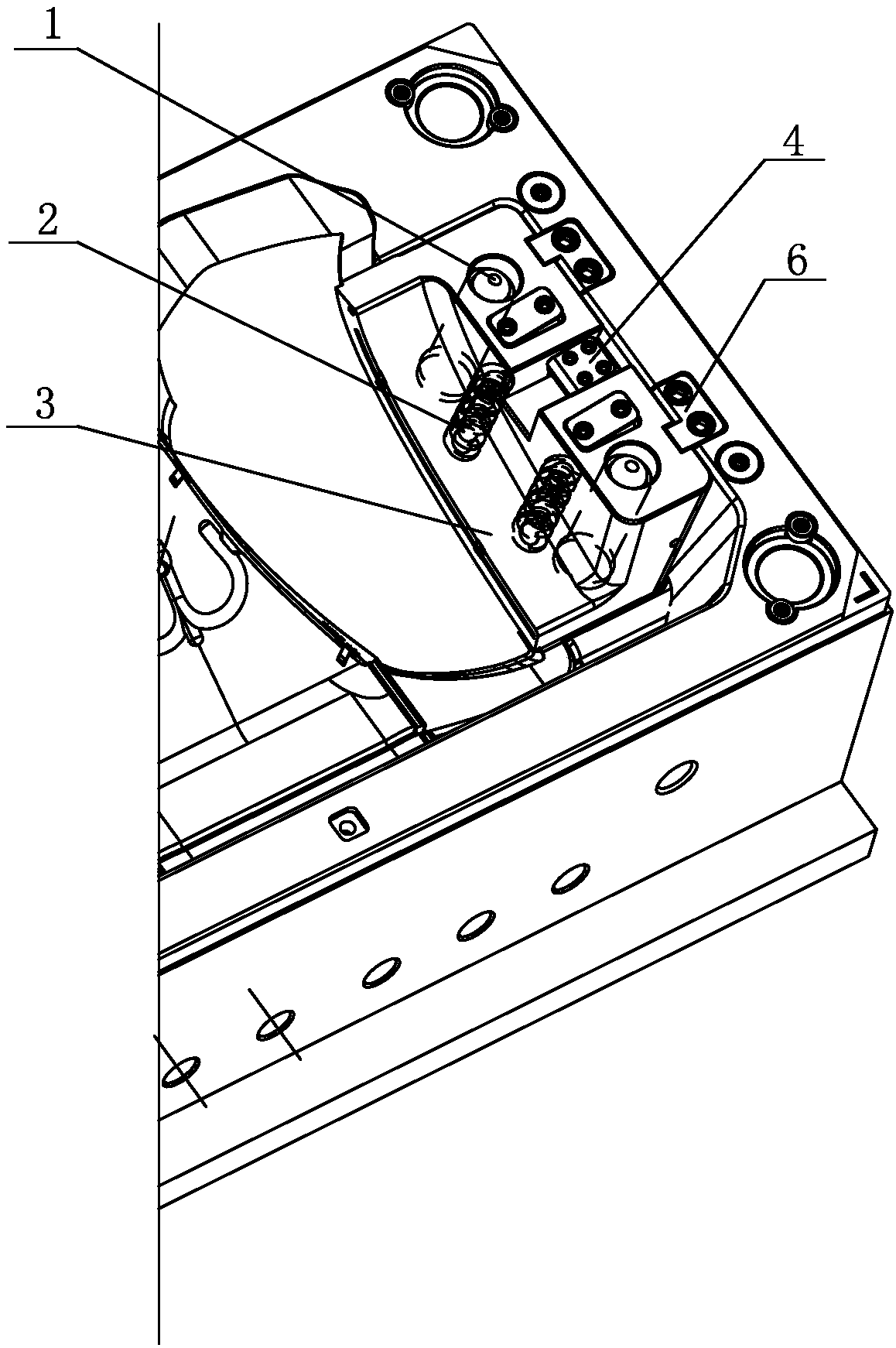

[0012] see figure 1 , 2 , a pop-up slider mechanism for an injection mold, comprising a fixed mold slider 3, an oblique guide post 1 is arranged on the fixed mold slider 3, a spring hole is provided on the fixed mold slider 3, the axis of the spring hole is aligned with the oblique The axes of the guide post 1 are parallel, and the spring hole is provided with a compression spring 2, the compression spring 2 is against the fixed mold slider 3, the upper end of the fixed mold slider 3 is provided with a limit block 6, and the limit block 6 is fixed on the mold frame. Die slide block 3 bottoms are provided with drag hook 5, and drag hook 5 one ends hook drag hook block 4, and drag hook 5 other ends are fixed on the moving mold, and drag hook block 4 is fixed on the fixed mold slide block 3. There are two oblique guide posts 1 and compression springs 2, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com