An automatic press-fitting device for motor rotor bearings

A press-fitting device and motor rotor technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the inner ring of the bearing cannot be clamped, and the stability of assembly quality cannot be overcome, so as to improve the stability and Reliability, overcoming poor stability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

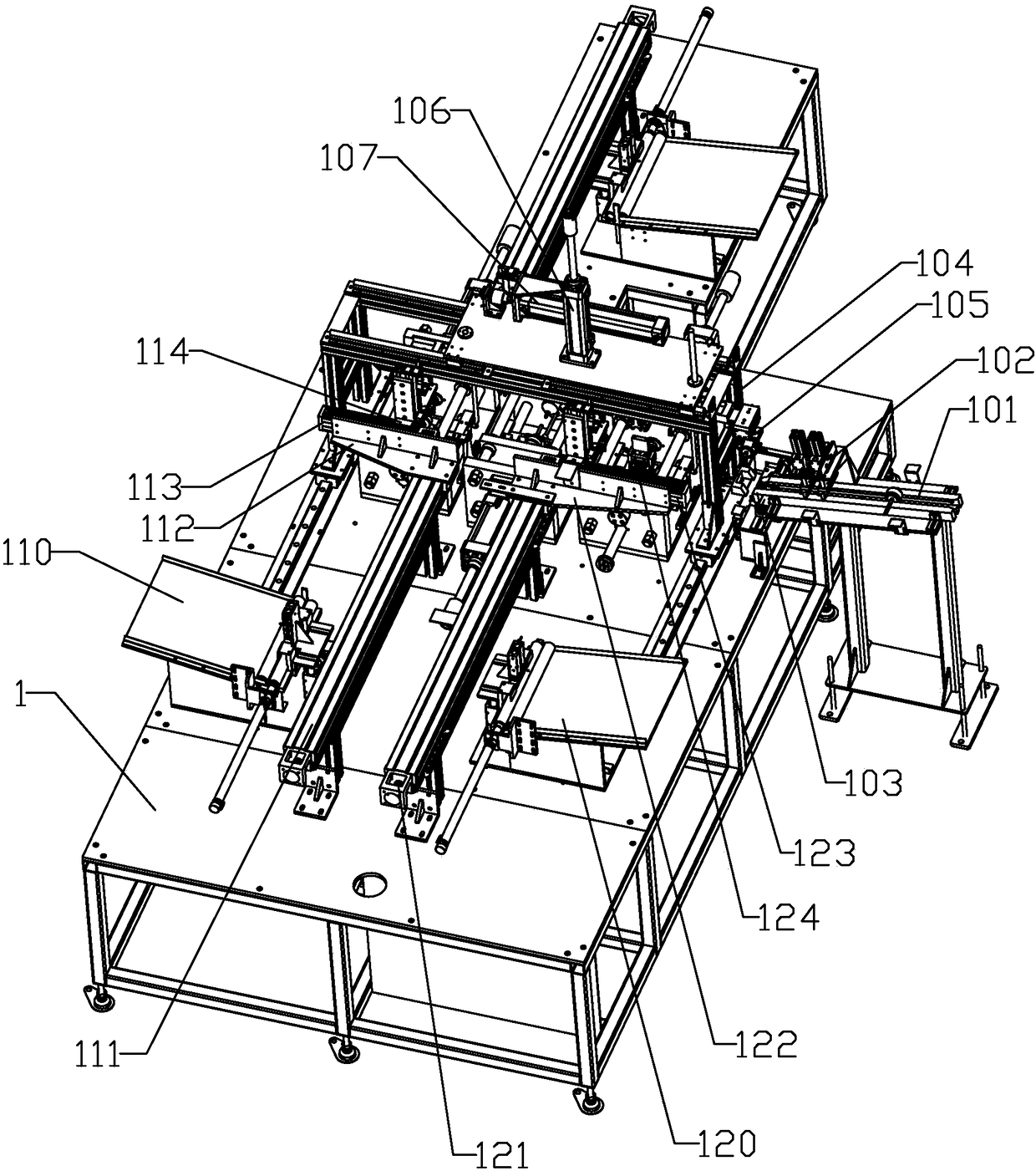

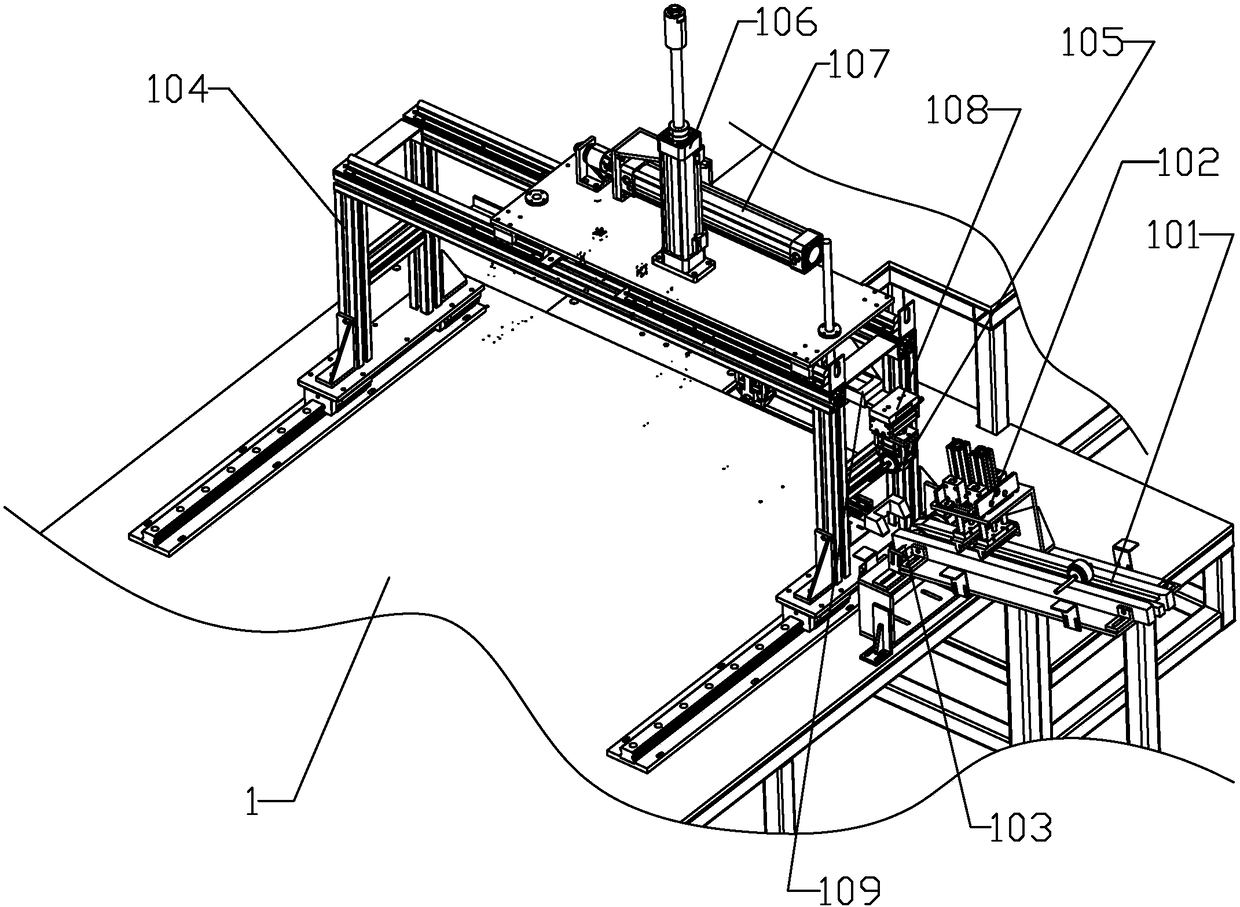

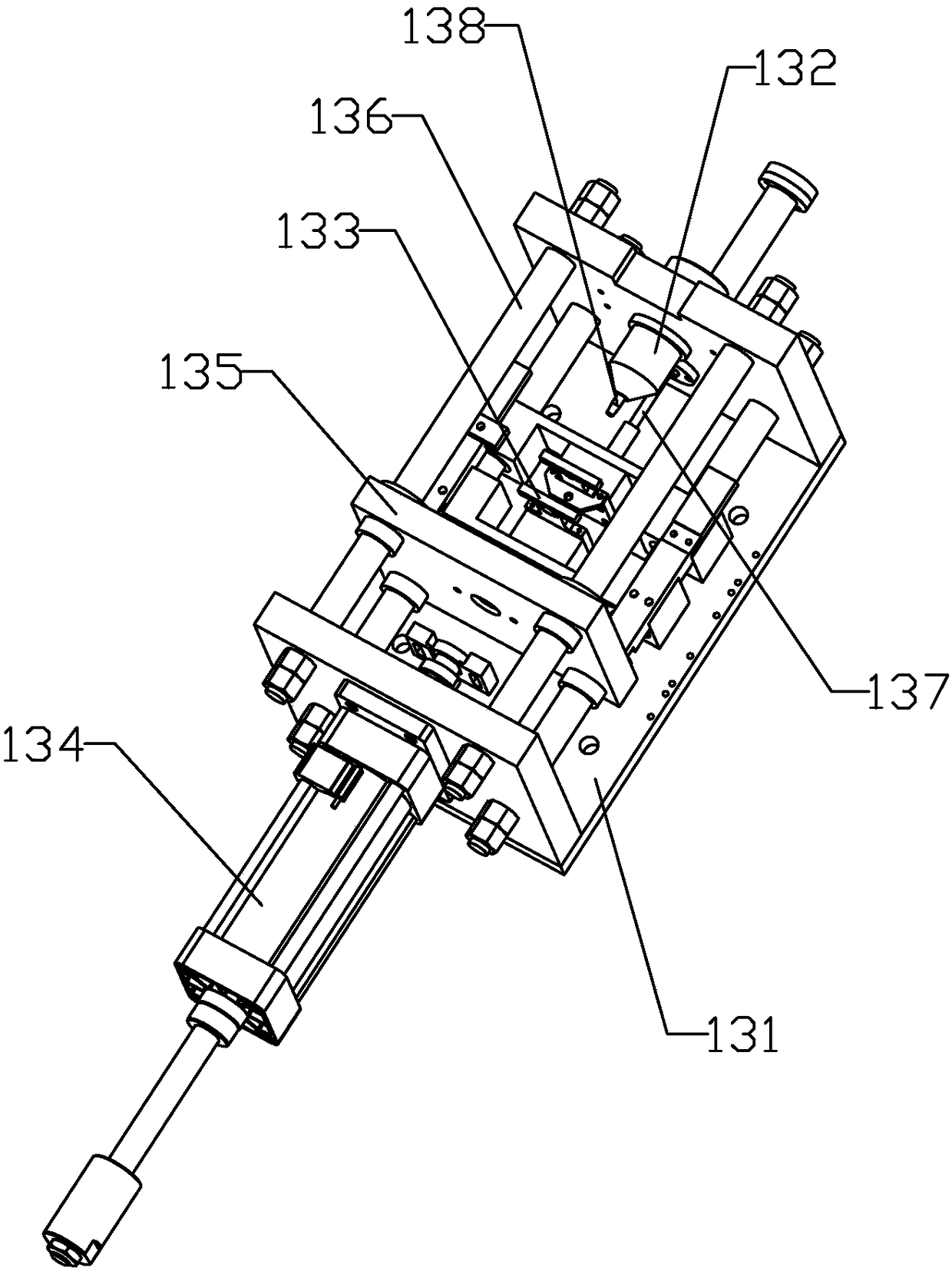

[0033] According to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 and attached Figure 5 As shown, the automatic press-fitting device for motor rotor bearings of the present invention mainly includes a frame 1 on which a rotor blanking and conveying mechanism, a bearing blanking and conveying mechanism, a magnetic ring blanking and conveying mechanism and a bearing press-fitting mechanism are respectively arranged. Among them, the electronic control parts of the rotor blanking conveying mechanism, bearing blanking conveying mechanism, magnetic ring blanking conveying mechanism and bearing press-fitting mechanism are all electrically connected with the circuit controller, and the adjustment of the circuit controller can change the above mechanisms in actual processing. time action. The outlet ends of the rotor blanking conveying mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com