BGA dismounting-to-welding tool used for printed board clamping and using method for BGA dismounting-to-welding tool

A technology of printed boards and tooling, which is applied to the field of BGA dismantling and welding tooling for clamping printed boards, and can solve the problems of high clamping position of printed boards, bending and deformation of printed boards, and low height of tooling , to achieve the effect of stable structure, large clamping force and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

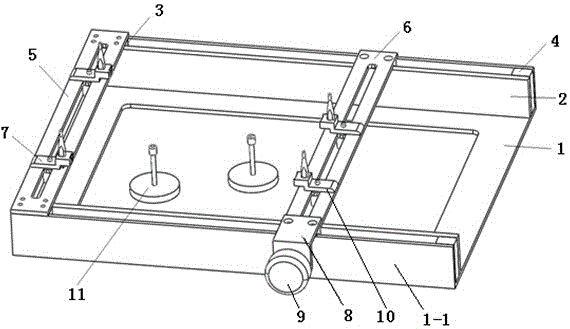

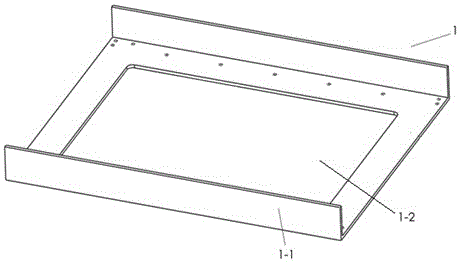

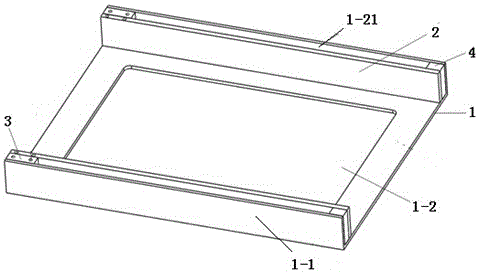

[0030] Such as Figure 1 to Figure 11 As shown, a BGA dismantling and welding tool for clamping printed boards includes a chassis 1, a guide baffle 2, a fixed end stopper 3, an end stopper 4, a fixed end guide rail 5, a sliding guide rail 6, a clamping Device I7, screw rack 8, hand screw 9, clamping device II10, printed board support device 11.

[0031] The clamping device I7 includes a clamping main body I7-1, a clamping pillar I7-2, a knurled screw I7-3, and a spring piece I7-4.

[0032] The clamping body Ⅰ7-1 is stepped, and there is a mounting screw hole Ⅰ7-5 on the convex surface at one end of the clamping device Ⅰ7, a groove is provided in front of the convex surface, and a reed screw is provided on the inner surface of the groove. Hole 7-6 is provided with a guide block I7-7 below the sinking surface of the other end of the clamping device I7, and a screw hole I7-8 is provided at the center of the guide block I7-7.

[0033] One end of the spring piece I7-4 is set in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com