Supporting structure of tunnel in bias salt cavity environment and construction method of supporting structure

A technology of support structure and construction method, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as tilting, collapse, and deformation of tunnel support structures, and achieve guaranteed support effects, reliable support effects, and construction The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

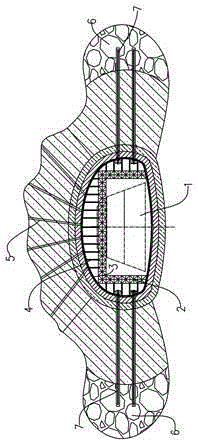

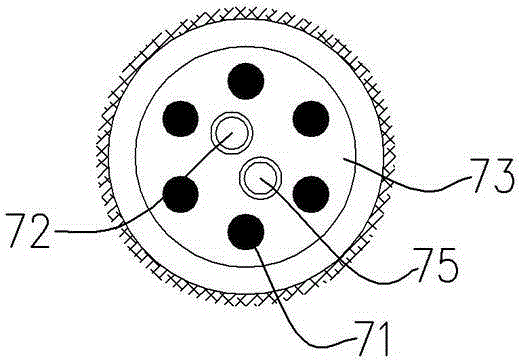

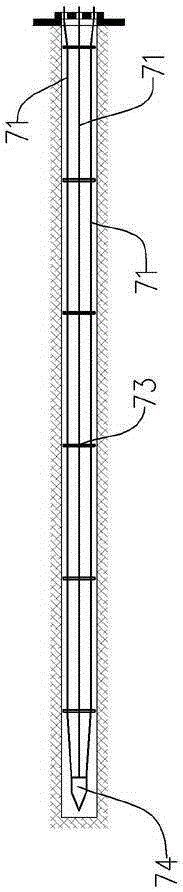

[0023] A tunnel support structure in a biased solution cavity environment, such as Figure 1-4 , in the tunnel 1, during the excavation construction process of the tunnel, a series of portal frames 2 arranged longitudinally and the steel wire mesh 3 provided on the tunnel wall are gradually arranged, and the portal frame is connected with the steel wire mesh provided on the tunnel wall through the support 4, and the steel mesh support; on the periphery of the tunnel, anchor rods 5 radially driven into the outer soil body are arranged, and the steel wire mesh is also fixedly connected with these anchor rods; There are multiple anchor cables 7 that go deep into the stable rock foundation 6 from the tunnel wall. The anchor cables are arranged horizontally or slightly upward; 6, the other end is anchored on the anchorage 8 set at the entrance of the anchor cable on the tunnel wall, and the anchorage is installed on the anchor cap 9 arranged at the entrance of the anchor cable, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com