Efficient cable cutting device for industry

A cutting device and industrial technology, applied in cleaning methods and appliances, cleaning methods using gas flow, chemical instruments and methods, etc., can solve the problems of low cutting efficiency, reduce weight, ensure worker safety, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

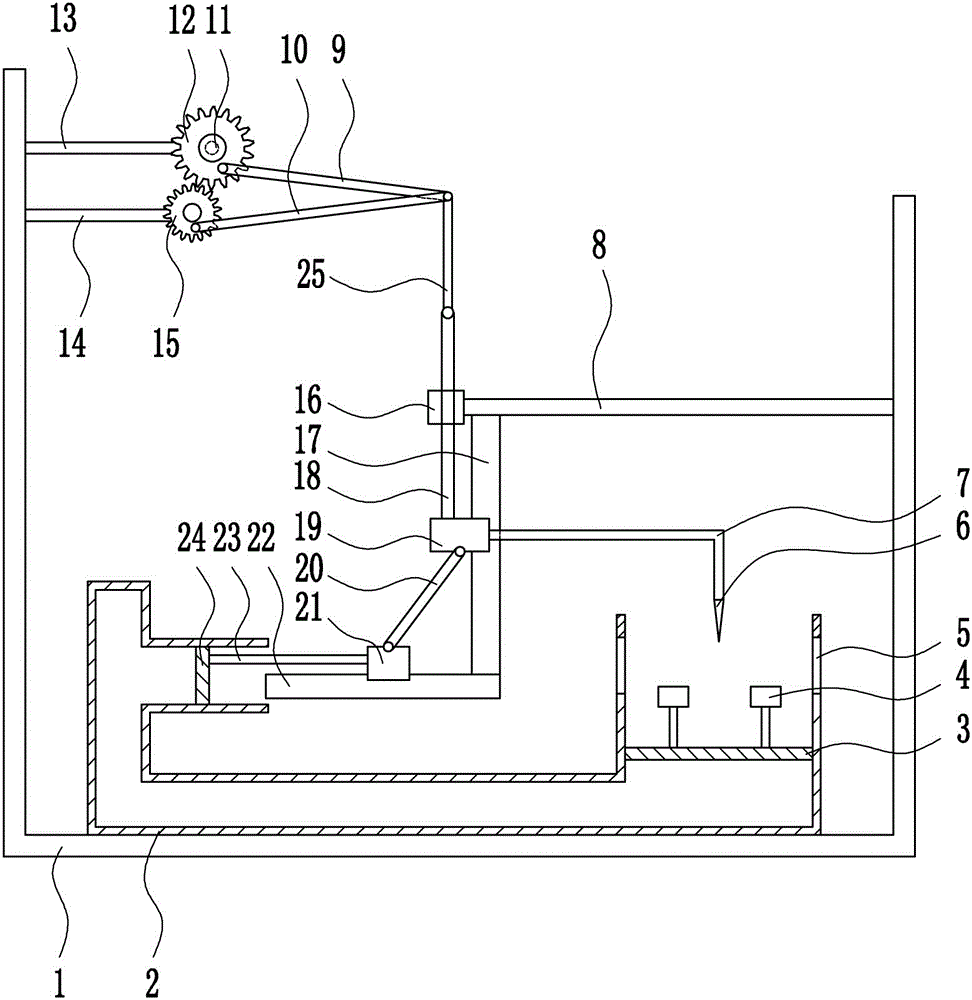

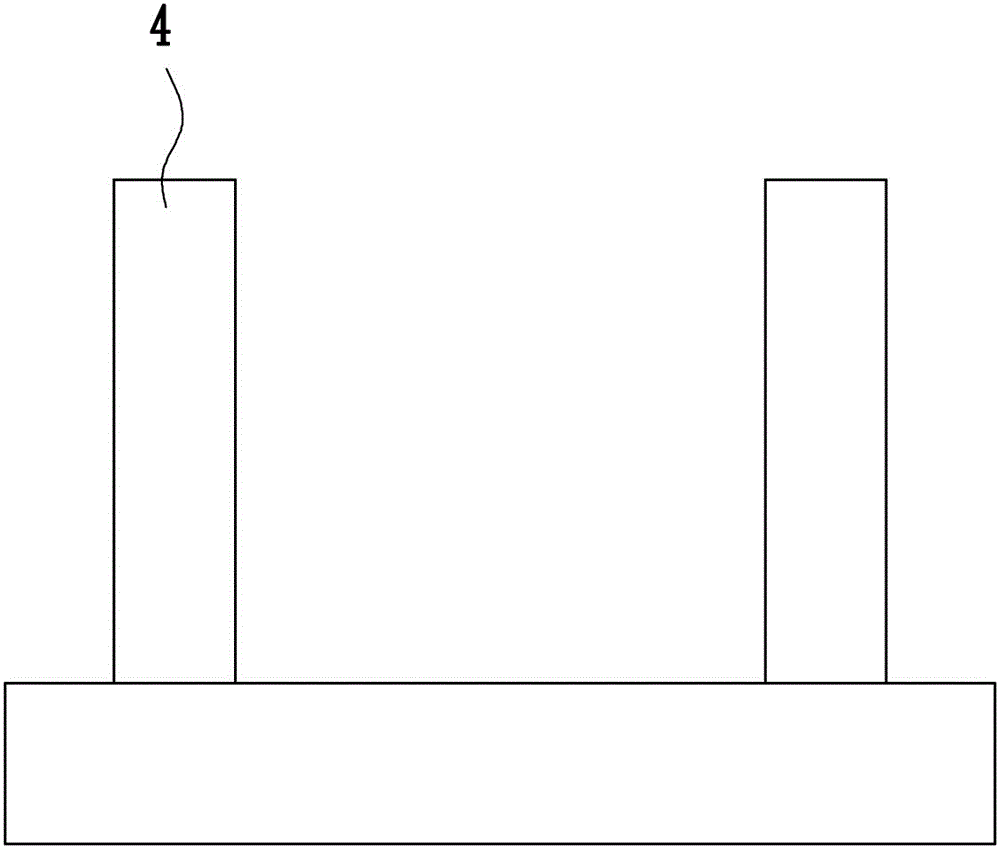

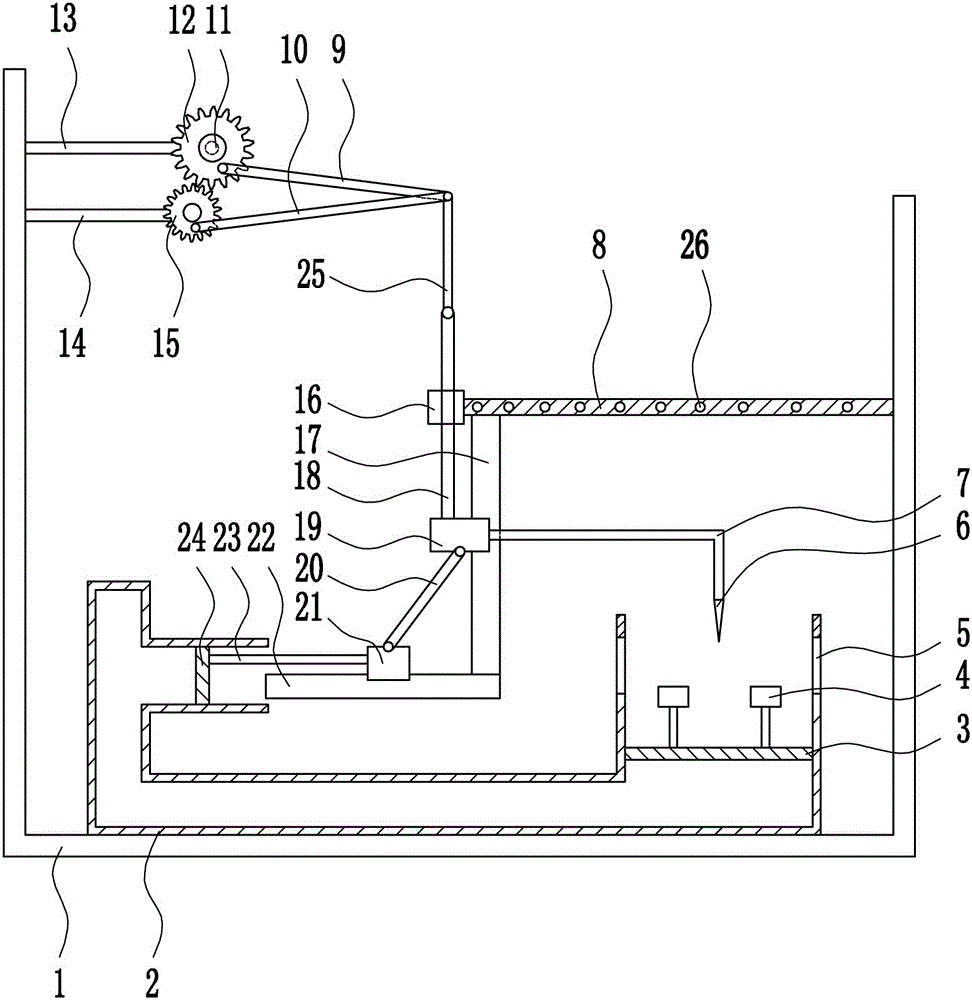

Embodiment 1

[0037] A high-efficiency cutting device for industrial cables, such as Figure 1-8 As shown, it includes a bracket 1, a cylinder body 2, a first piston 3, a thumb cylinder 4, a cutting knife 6, a fifth connecting rod 7, a third connecting rod 8, a first connecting rod 9, a second connecting rod 10, a rotating Motor 11, first gear 12, first pole 13, second pole 14, second gear 15, sliding sleeve 16, first fixed pulley 17, lifting rod 18, first slider 19, fourth connecting rod 20 , the second slider 21, the second slide rail 22, the push rod 23, the second piston 24 and the sixth connecting rod 25; the inner bottom of the bracket 1 is provided with a cylinder 2, and the cylinder 2 is provided with a first piston 3 and a first piston 3 Two pistons 24, the first piston 3 is located at the left side of the second piston 24, the first piston 3 and the second piston 24 are all matched with the inner wall of the cylinder body 2, and the left wall and the right wall on the right side o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com