Microwave pyrolysis method for by-product salt

A by-product, microwave technology, used in chemical instruments and methods, pyrolysis reaction, solid waste removal, etc., can solve problems such as bonding equipment and uneven heating, and achieve high heating efficiency, uniform heating, and shortened heating time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

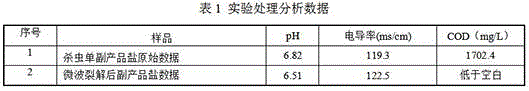

[0027] The by-product salt used in this experiment comes from a pesticide chemical company, which is mainly the by-product salt (primary filter salt) produced in the production process of insecticidal sheets, and the main component is sodium chloride salt. The water content of the sample is about 12%, and the concentration of organic matter is relatively high. A certain quality of by-product salt was weighed and placed in a microwave cracking furnace with a set temperature of 400 °C and a cracking time of 4 hours. The treatment effect is shown in Table 1.

[0028]

[0029] Remarks: The data is measured by dissolving 10g dry weight by-product in 100ml pure water.

[0030] It can be seen from the data in Table 1 that after microwave cracking, the salt organic matter in the by-products has been lower than the detection blank, indicating that the organic matter has been completely decomposed and the treatment effect is excellent.

Embodiment 2

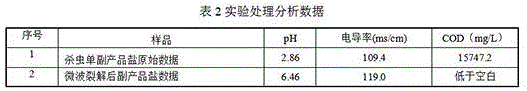

[0032] The by-product salt used in this experiment comes from a pesticide chemical company, which is mainly the by-product salt (secondary filter salt) produced in the production process of insecticidal sheets, and the main component is sodium chloride salt. The moisture content of the sample is about 18%, and the concentration of organic matter is relatively high. A certain quality of by-product salt was weighed, placed in a microwave cracking furnace, the set temperature was 600°C, and the cracking time was 4h. The treatment effect is shown in Table 2.

[0033]

[0034] Remarks: The data is measured by dissolving 10g dry weight by-product in 100ml pure water.

[0035] It can be seen from the data in Table 2 that after microwave cracking, the salt organic matter in the by-products has been lower than the detection blank, indicating that the organic matter has been completely decomposed and the treatment effect is excellent.

Embodiment 3

[0037] The by-product salt used in this experiment comes from a pesticide chemical company, which is mainly the by-product salt (primary filter salt) produced in the production process of insecticidal sheets, and the main component is sodium chloride salt. The water content of the sample is about 12%, and the concentration of organic matter is relatively high. Take by-product salt of a certain quality, place in microwave cracking furnace, setting temperature is 200 ℃, cracking time is 6h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com