Cleaning device and method of full-automatic solar panel heating type tubular rod

A cleaning device and heating device technology, applied in cleaning methods and appliances, chemical instruments and methods, and dust removal, etc., can solve problems such as high manual labor intensity, easy pipe jamming, difficult maintenance, etc., and achieve the effect of reducing manual labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

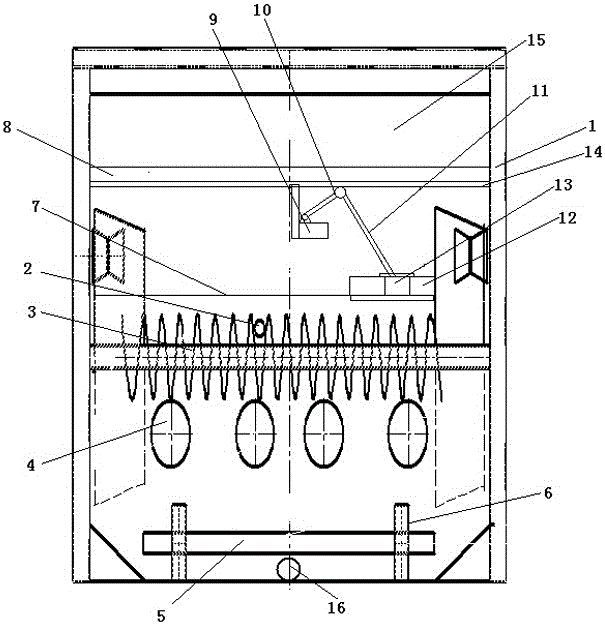

[0017] combined with Figure 1-4 , to further describe the present invention:

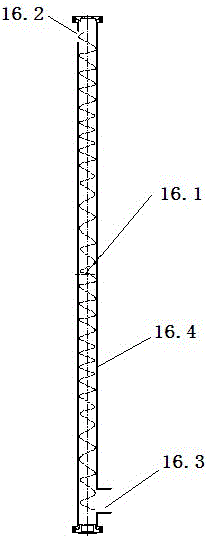

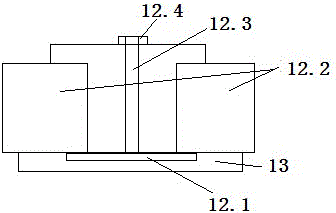

[0018] The technical solution of the present invention is: including heating device, insulation layer (1), propulsion auger (3), heating pipe (4), sediment cleaning device, horizontal sludge cleaning coupling shaft (5), scraper (6), The propulsion rod (8) and the oil suction device are provided with an insulation layer (1) on the outside of the body (15), and a propulsion auger (3) is provided in the inner middle of the body (15), and the pipe rod (2) is placed on the propulsion auger. In the groove of the dragon (3), a plurality of evenly distributed heating pipes (4) are arranged at the lower part of the propulsion auger (3), and a sediment cleaning device is arranged at the lower part of the heating pipes (4); The device includes a horizontal sludge cleaning coupling (5), a scraper (6), and a screw sand pump (16). Vertical scrapers (6) are installed on both sides of the horizontal sludge cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com