Preparation method of high efficiency CdS-CdIn2S4 superstructure photocatalyst

A technology of cds-cdin2s4 and photocatalyst, which is applied in the field of preparation of CdS-CdIn2S4 superstructure photocatalyst, can solve the problems of low photocatalytic efficiency and achieve the effect of large specific surface area, good catalytic activity and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Synthesis of CdS nanowires

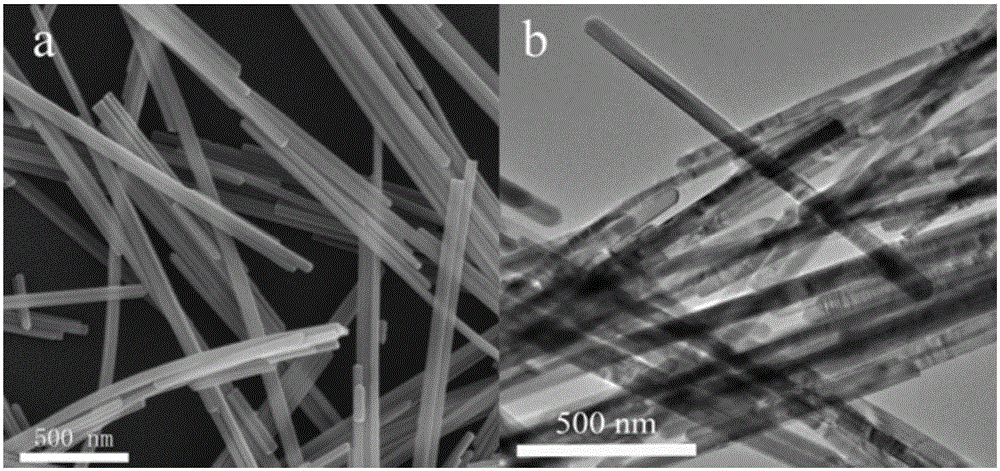

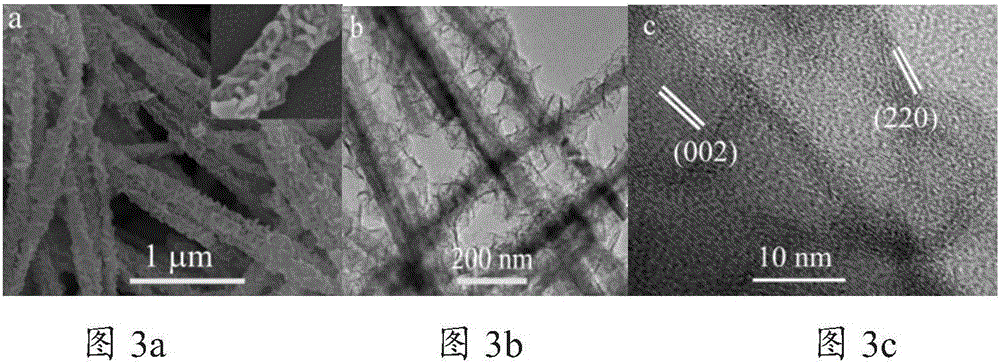

[0034] Add 102mL of ethylenediamine, 18mL of n-dodecanethiol, 3.5mmol of cadmium acetate and 7mmol of sodium diethyldithiocarbamate into the cleaned and dried polytetrafluoroethylene liner (V=150-180mL) , stirred for 5 minutes to dissolve it. After the reaction kettle was screwed tightly and sealed, it was placed in an electric heating constant temperature blast drying oven, and reacted at 180° C. for 48 hours. Cool naturally to room temperature after the reaction, take out the product, centrifuge, wash with absolute ethanol to remove organic matter attached to the surface of the product, and then alternately wash with ethanol and high-purity water for 3 times. Finally, the sample product was put into a vacuum drying oven and dried at 60° C. for 4 hours. figure 1 SEM and TEM images of the obtained CdS nanowires. It can be seen from the figure that the product is a nanowire structure with a length of about 1.5 μm and a diameter of abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com