Preparation method of Corbicula fluminea polypeptide chelated zinc

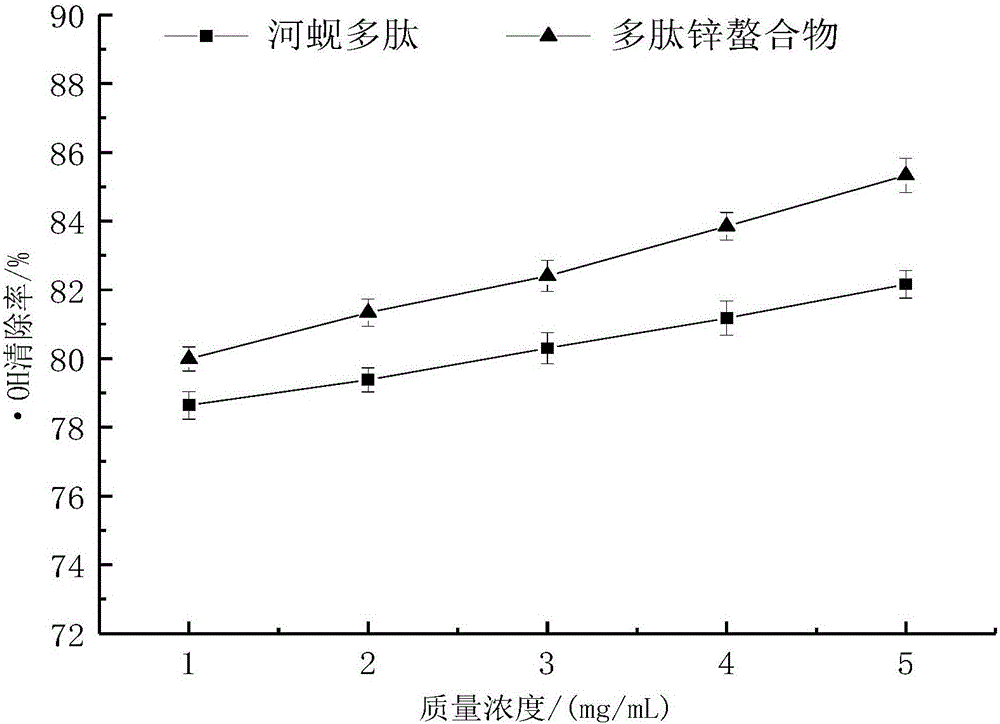

A technology for chelating zinc and clam, which is applied to the functions of food ingredients, food science, food ingredients, etc., can solve problems such as hindering the absorption of nutrients, and achieve good chelation effects, increased activity, and good biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Take the bagged frozen clam meat and thaw it under running water at room temperature. Wash the thawed clam meat to remove impurities such as sediment, squeeze dry and weigh. Put the river clam meat into a high-speed tissue grinder and add pure water to homogenize it, which is the river clam homogenate.

[0037] (2) Add 2.0% neutral protease according to the enzyme activity to the above clam homogenate, based on the quality of the clam homogenate, and enzymolyze it in a water bath at 56°C for 4 hours.

[0038] (3) After enzymatic hydrolysis, keep it in a constant temperature water bath at 100° C. for 20 minutes to inactivate the enzyme.

[0039] (4) Cool down after inactivating the enzyme, and perform centrifugation in a high-speed centrifuge at a speed of 4000r / min for 30 minutes to remove the precipitate, and the obtained supernatant is the clam enzymatic hydrolysis solution.

[0040] (5) Vacuum freeze-dry the above-mentioned clam enzymatic hydrolyzate for 10 h t...

Embodiment 2

[0048] (1) Take the bagged frozen clam meat and thaw it under running water at room temperature. Wash the thawed clam meat to remove impurities such as sediment, squeeze dry and weigh. Put the river clam meat into a high-speed tissue grinder and add pure water to homogenize it, which is the river clam homogenate.

[0049] (2) Add 1.0% neutral protease to the above clam homogenate based on the quality of the clam homogenate, and hydrolyze it in a water bath at 56°C for 4 hours.

[0050] (3) After enzymatic hydrolysis, keep it in a constant temperature water bath at 100° C. for 20 minutes to inactivate the enzyme.

[0051] (4) Cool down after inactivating the enzyme, and perform centrifugation in a high-speed centrifuge at a speed of 4000r / min for 30 minutes to remove the precipitate, and the obtained supernatant is the clam enzymatic hydrolysis solution.

[0052] (5) Vacuum freeze-dry the above-mentioned clam enzymatic hydrolyzate for 10 h to prepare the clam polypeptide powd...

Embodiment 3

[0060] (1) Take the bagged frozen clam meat and thaw it under running water at room temperature. Wash the thawed clam meat to remove impurities such as sediment, squeeze dry and weigh. Put the river clam meat into a high-speed tissue grinder and add pure water to homogenize it, which is the river clam homogenate.

[0061] (2) Add 1.0% neutral protease to the above clam homogenate based on the quality of the clam homogenate, and hydrolyze it in a water bath at 56°C for 4 hours.

[0062] (3) After enzymatic hydrolysis, keep it in a constant temperature water bath at 100° C. for 20 minutes to inactivate the enzyme.

[0063] (4) Cool down after inactivating the enzyme, and perform centrifugation in a high-speed centrifuge at a speed of 4000r / min for 30 minutes to remove the precipitate, and the obtained supernatant is the clam enzymatic hydrolysis solution.

[0064] (5) Vacuum freeze-dry the above-mentioned clam enzymatic hydrolyzate for 10 h to prepare the clam polypeptide powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com