Reinforced concrete structure X-ray imaging detector

A reinforced concrete, imaging detection technology, applied in the direction of using radiation for material analysis, etc., can solve the problems of incomplete facts, incomplete test results, inconsistencies, etc., to optimize detection, ensure stability and comprehensiveness, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

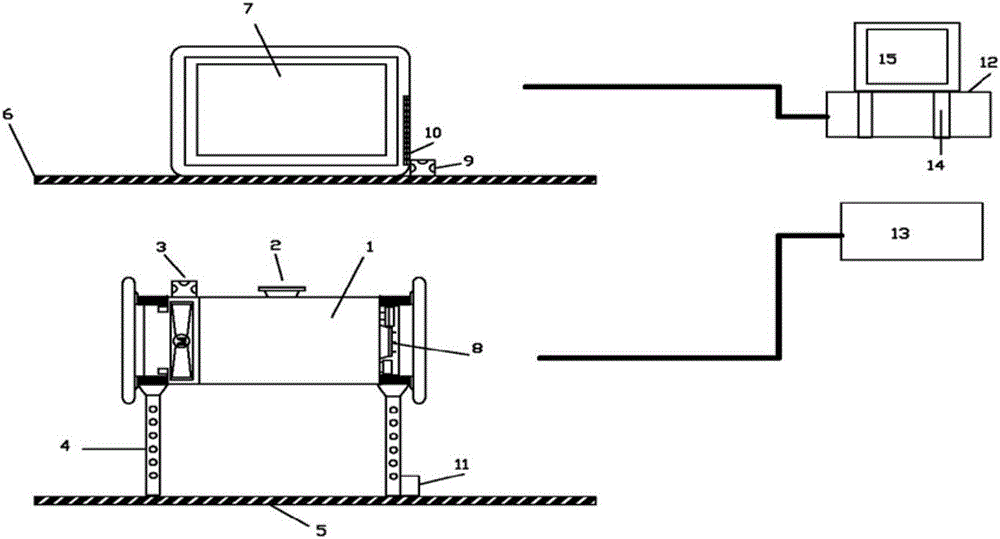

[0012] Such as figure 1 Shown is a specific embodiment of a reinforced concrete structure X-ray imaging detection instrument of the present invention. This embodiment comprises an X-ray generating device 1, a detection mechanism, a computer 12 and a display screen 15 connected in sequence, the X-ray generating device 1 includes an X-ray source window 2, and X-rays are generated by the X-ray generating device 1 and enter the detection mechanism, and Including an X-ray modulator 13, the X-ray generator 1 and the X-ray modulator 13 are connected through a data acquisition cable 8, and the X-ray modulator 13 collects feedback information through the data acquisition cable 8 to adjust the size of the output high-frequency power supply Thereby making the X-ray generating device 1 generate adjustable X-ray dose; adopting the above-mentioned technical scheme,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com