A variable diameter leather cup type pig

A leather cup and sensor technology, applied in the direction of pipe elements, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of resistance in the recovery process and the poor sealing of the pipe plugger, and achieve reliable reduction of diameter recovery, reducing Resistance, the effect of reducing the risk of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

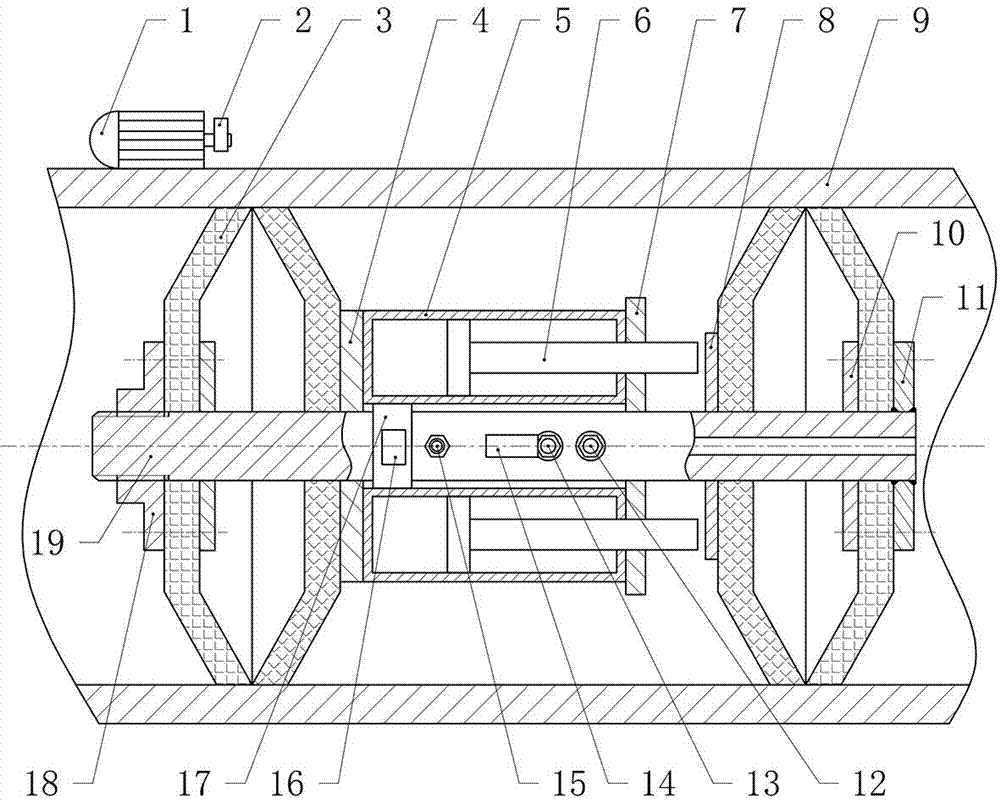

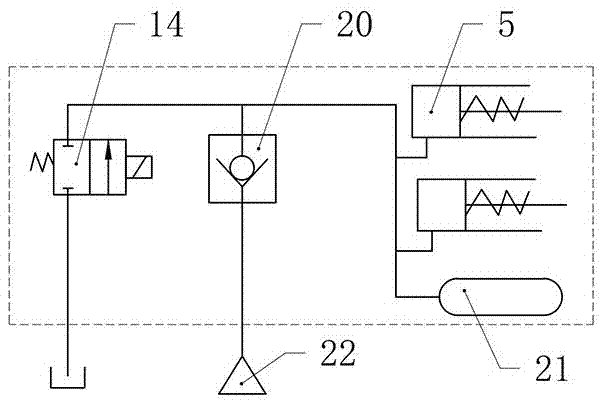

[0016] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below figure 1 , figure 2 The present invention is described below. The positional relationship of up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0017] The leather cup 3 is dish-shaped with a central hole, and the mandrel 19 passes through the central hole of the leather cup 3, and two leather cups 3 are respectively arranged at the front and rear ends of the mandrel 19. The two cups 3 at the front end of the mandrel 19 are arranged oppositely and fastened together, and a cavity is formed in the center of the two cups 3 at the front end of the mandrel 19 . The two cups 3 at the rear end of the mandrel 19 are oppositely arranged and fastened together, and a cavity is formed in the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com