Coating composition for lubricating coating film

A technology of lubricating coating and composition, applied in the field of manufacturing the sliding member, can solve the problems of damage to the adhesion of the substrate and the coating film, the lack of flexibility of the coating film, etc., and achieve excellent sliding properties, excellent sliding durability, The effect of excellent adhesion and following ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1 to 13 and comparative example 1 to 5

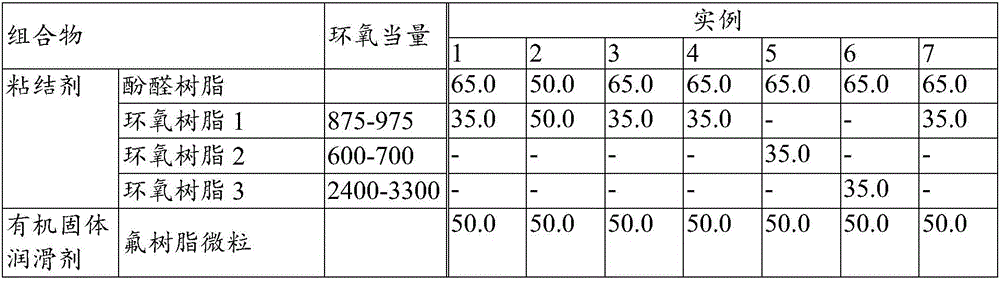

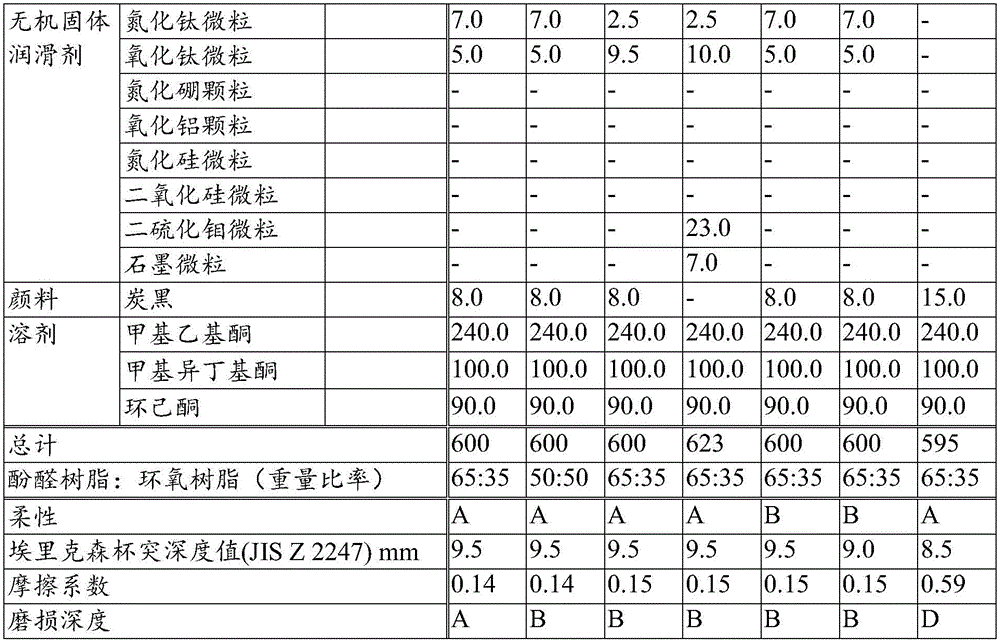

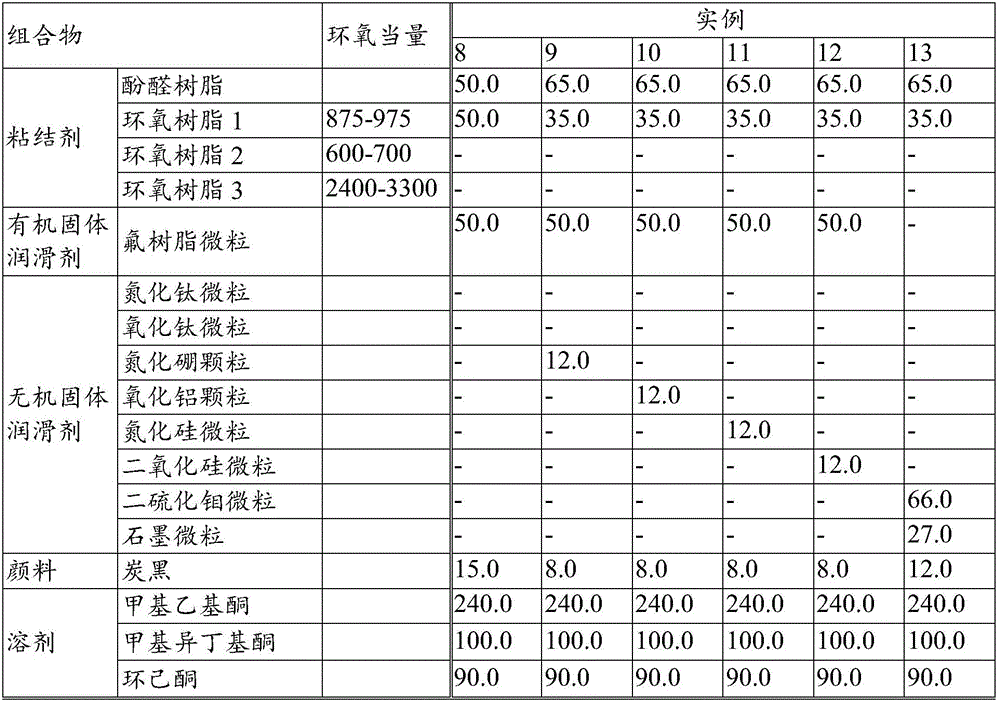

[0161] The coating compositions for the lubricating coating film of Examples 1 to 13 and Comparative Examples 1 to 5 are shown in Table 1-1, 1-2 and Table 2 by each component shown in Table 1-1, 1-2 and the ratios in Table 2 were mixed. It should be noted that the numbers shown in Tables 1-1, 1-2 and Table 2 represent parts by weight. In addition, the solid lubricants used in the table are as follows:

[0162] - Fluororesin microparticles: polytetrafluoroethylene powder (100% by weight of dry solid content) having a median diameter of 2 to 7 micrometers as measured by a laser diffraction scattering type particle size distribution method.

[0163] - Titanium nitride microparticles: black titanium nitride powder (100% by weight dry solids content), with a median diameter of 0.8 to 1.0 micrometer, as measured by a particle size distribution method of the laser diffraction scattering type.

[0164] - Titanium oxide microparticles: white rutile type titanium oxide powder (100% by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com