LED downlight light source integrated circuit and led downlight

An LED downlight and integrated circuit technology, which is applied in the field of LED downlight source integrated circuits, can solve the problems of efficiency, constant current performance dimming effect defects, high assembly process requirements, increased component consumption, etc., and achieves superior power conversion. Efficiency and dimming effect, low cost, effect of stable constant current performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

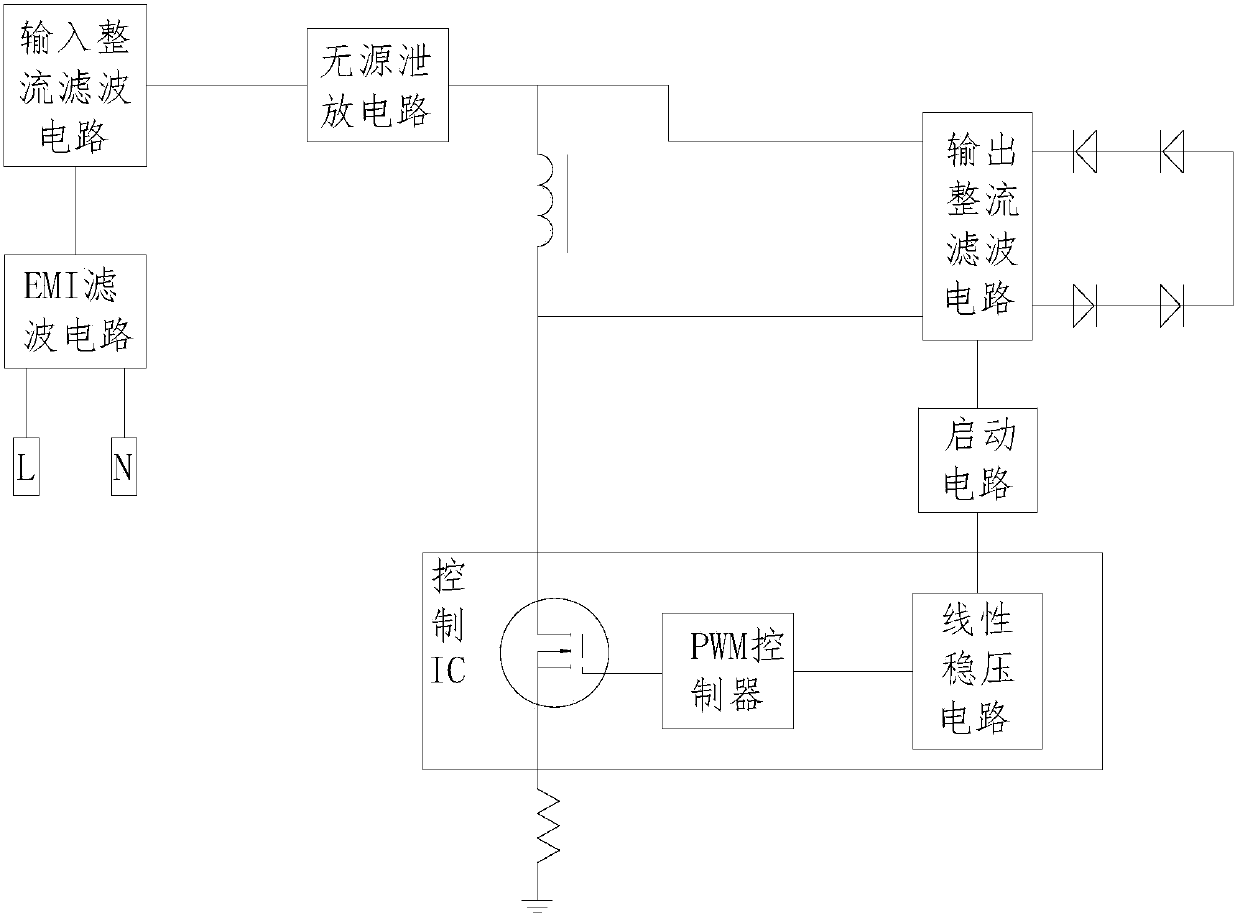

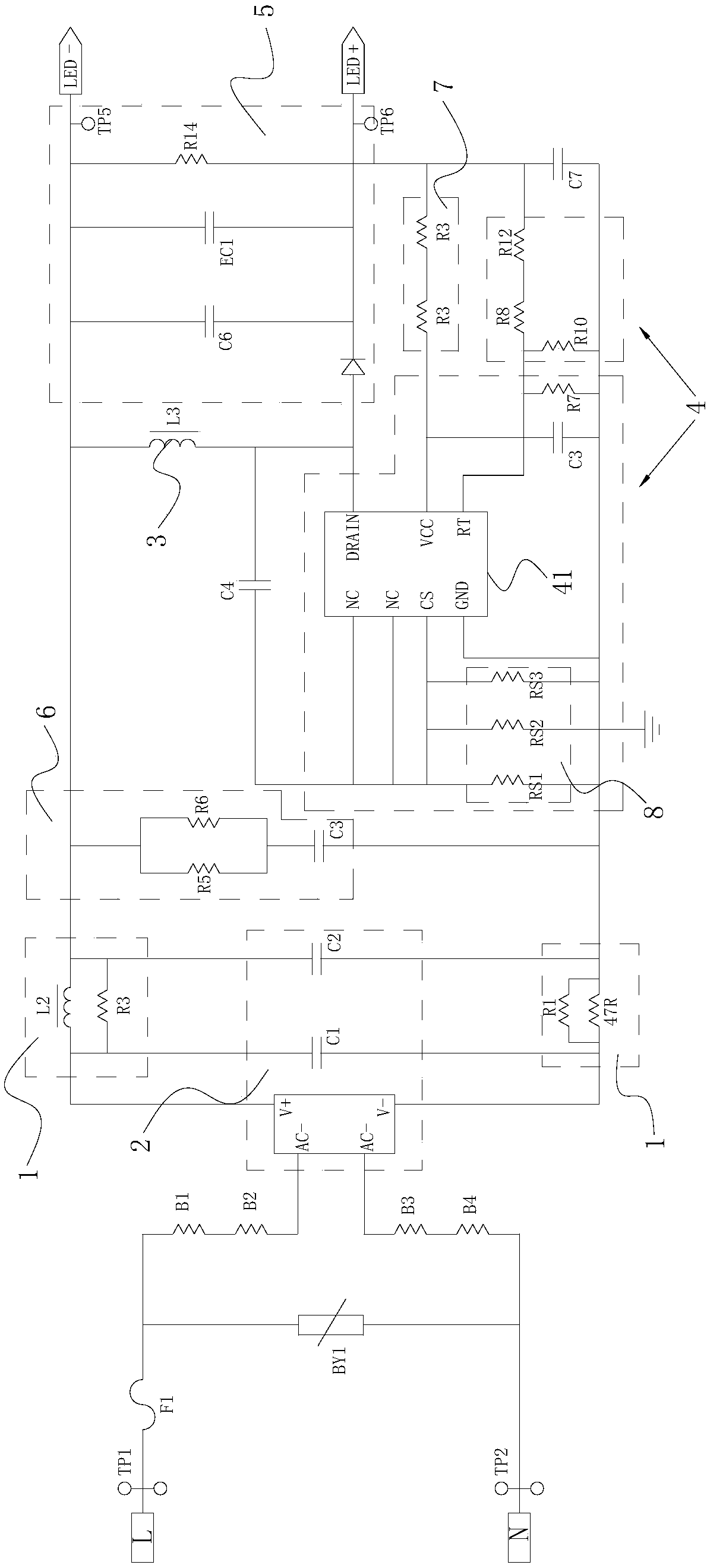

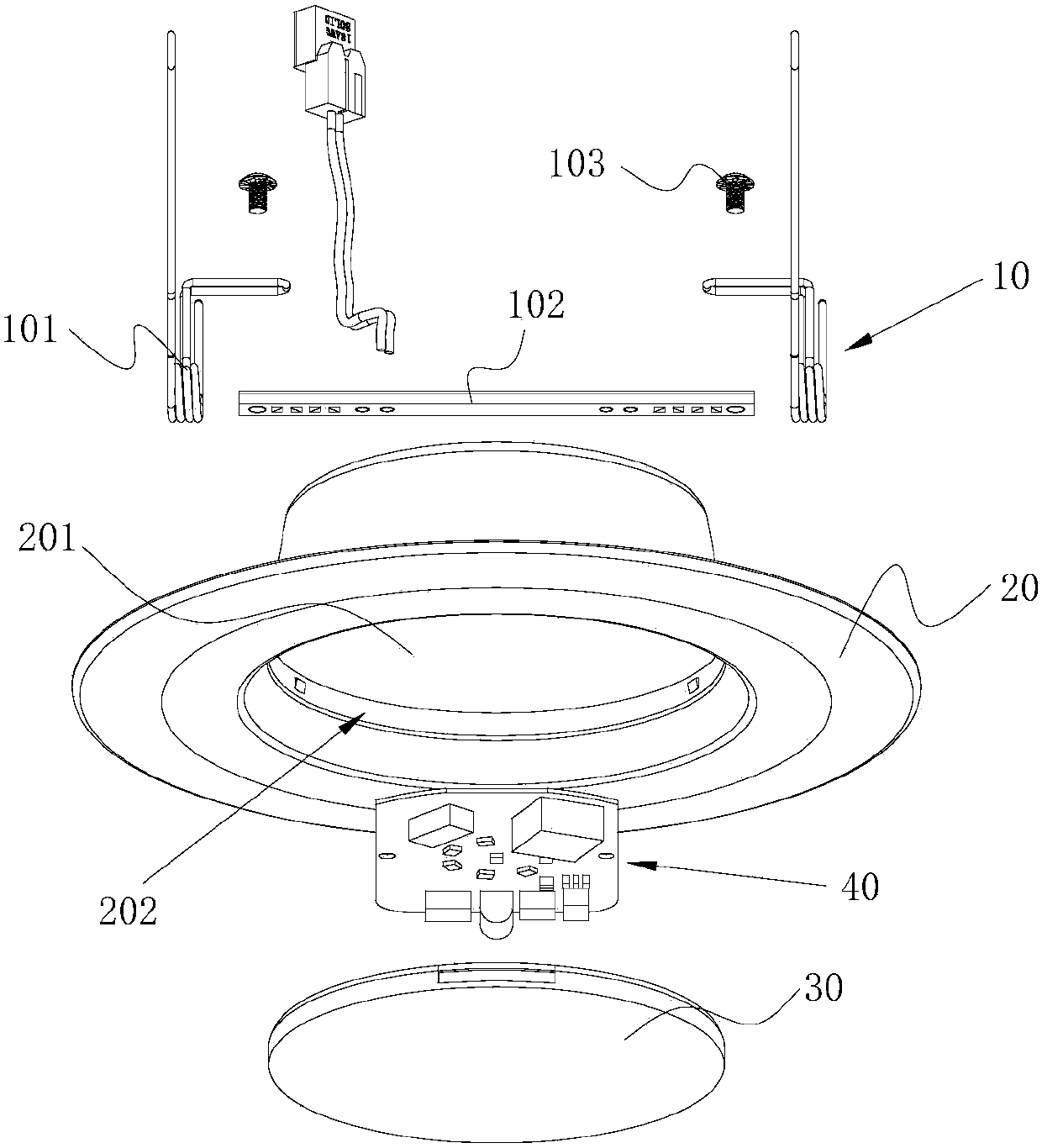

[0022] see Figure 1 to Figure 2 , an LED downlight light source integrated circuit provided by the present invention includes an EMI filter circuit 1, an input rectification filter circuit 2, a power inductor 3, a control IC4 and an output rectification filter circuit 5; the EMI filter circuit 1 is used to filter out AC Interference signals in the input electricity, the output end of the EMI filter circuit 1 is connected to the input end of the input rectification filter circuit 2, and the input rectification filter circuit 2 is used to convert the alternating current after filtering out the interference signal into direct current; The control IC4 includes a MOS transistor (not shown), a PWM controller 41 and a linear voltage regulator circuit, one end of the power inductor 3 is connected to the output end of the input rectification filter circuit 2, and the other end is connected to the MOS Tube connection, and the power inductor 3 outputs an oscillating voltage to the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com