Winding and insulating tape wrapping continuous synchronous operation method and device for winding machine

A winding machine and insulating tape technology, which is applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problem that the tape and winding equipment cannot be continuously operated at the same time, so as to reduce the occupation rate of employees and equipment , increase output, improve the effect of tape quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

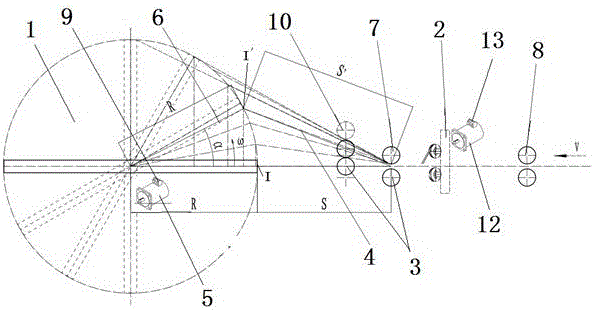

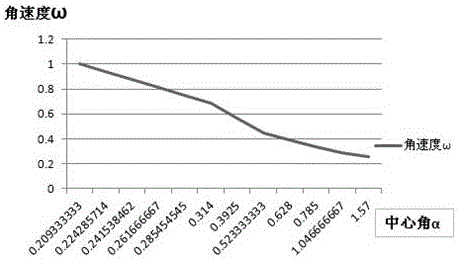

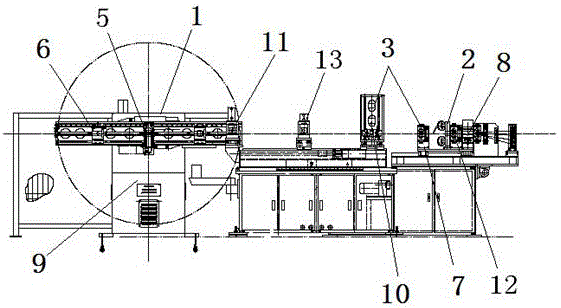

[0053] As shown in the accompanying drawings, the present invention relates to a continuous winding and insulation wrapping device for a winding machine, which includes a winding mechanism 1 and a wrapping mechanism 2. After the wire device 3 and the electromagnetic wire 4 are wrapped by the tape-wrapping mechanism 2, they are sent to the strip-shaped winding arm 6 of the winding mechanism 1 through the wire-managing device 3, and the strip-shaped winding arm 6 is driven by the winding arm motor 5 to rotate. Winding into a coil; a speed sensor 8 for detecting the linear motion speed of the electromagnetic wire during wrapping is provided at the entrance or exit of the electromagnetic wire 4 of the wrapping mechanism 2, and a winding arm motor control system 9 is also provided in the winding machine. The winding arm motor control system 9 monitors and adjusts the rotation speed of the winding arm 6 to ensure that the strip winding arm 6 has a relatively stable linear speed when ...

Embodiment 2

[0064] The structure of the second embodiment is the same as the principle of the first embodiment, and the structure is basically the same. It is a continuous winding and insulation wrapping device for a winding machine, including a winding mechanism and a wrapping mechanism. There is a wire management device between the mechanisms. After the electromagnetic wire is wrapped by the tape mechanism, it is sent to the ring or ellipse winding arm of the winding mechanism through the wire management device. The ring or ellipse winding arm motor drives the winding arm to rotate and wind. into a coil; only a speed sensor for detecting the linear motion speed of the electromagnetic wire during wrapping is provided between the outlet of the electromagnetic wire of the wrapping mechanism and the entrance of the wire management device, and the winding machine is driven by a servo motor, and the winding The machine is also equipped with a servo programmable control system for the servo mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com