A kind of production method of natural coal char composite graphite negative electrode material

A technology of composite graphite and negative electrode materials, applied in battery electrodes, electrochemical generators, electrical components, etc., to achieve the effect of improving compaction density, excellent cycle performance, high and low temperature performance, and shortening the path of lithium insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

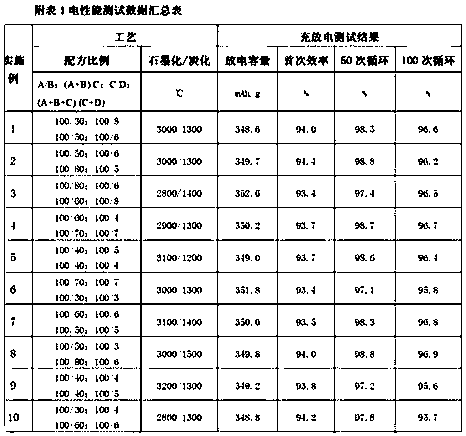

Examples

Embodiment 1

[0027] Weigh 200kg of coal-based coke raw material A, and pulverize it into a fine powder with a particle size D50 of 8 µm.

[0028] Weigh 50kg of asphalt raw material C and carry out jet milling, and the crushed particle size is ≤2µm.

[0029] Weigh 100kg of crushed raw material A, add 30kg of raw material B, mix uniformly at room temperature, then fuse for 30 minutes, then add 10.4kg of crushed raw material C, modify at 300~600°C, Graphitization is carried out at ℃.

[0030] Weigh 10 kg of crushed raw material C, add 5 kg of raw material D, and perform airflow mixing.

[0031] Weigh 50kg of the graphitized material (A+B+C), add 3kg of the air-mixed material (C+D), mix evenly, and then carbonize at 1300°C.

[0032] After the carbonized material is cooled to room temperature, it is dispersed, screened, and impurity removed to obtain the product.

[0033] After the product of the present invention is subjected to a series of processes such as beating and coating, it is then ...

Embodiment 2

[0035] Weigh 200kg of coal-based coke raw material A and pulverize it into fine powder with a particle size D50 of 6 µm.

[0036] Weigh 50kg of asphalt raw material C and carry out jet milling, and the crushed particle size is ≤2µm.

[0037] Weigh 100kg of crushed raw material A, add 50kg of raw material B, mix uniformly at room temperature, then fuse for 30 minutes, then add 9kg of crushed raw material C, modify at 300~600°C, under graphitization.

[0038] Weigh 10 kg of crushed raw material C, add 8 kg of raw material D, and perform airflow mixing.

[0039] Weigh 50kg of the graphitized material (A+B+C), add 2.5kg of the air-mixed material (C+D), mix evenly, and then carbonize at 1300°C.

[0040] After the carbonized material is cooled to room temperature, it is dispersed, screened, and impurity removed to obtain the product.

[0041] After a series of processes such as beating and coating, the product of the present invention is then made into a LIR2430 type button batte...

Embodiment 3

[0043] Weigh 200kg of coal-based coke raw material A and pulverize it into a fine powder with a particle size D50 of 7 µm.

[0044] Weigh 50kg of asphalt raw material C and carry out jet milling, and the crushed particle size is ≤2µm.

[0045] Weigh 100kg of crushed raw material A, add 80kg of raw material B, mix uniformly at room temperature, then fuse for 30 minutes, then add 10.8kg of crushed raw material C, modify at 300~600°C, Graphitization is carried out at ℃.

[0046] Weigh 10 kg of crushed raw material C, add 6 kg of raw material D, and perform airflow mixing.

[0047] Weigh 50kg of the graphitized material (A+B+C), add 4kg of the air-mixed material (C+D), mix evenly, and then carbonize at 1400°C.

[0048] After the carbonized material is cooled to room temperature, it is dispersed, screened, and impurity removed to obtain the product.

[0049] After the product of the present invention is subjected to a series of processes such as beating and coating, it is then m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com