A non-probabilistic reliability optimization method for composite laminates

A technology of composite material layer and optimization method, which is applied in the field of optimal design of composite material laminated board structure, can solve problems such as immaturity and waste of resources, and achieve the effects of reducing lightweight design, optimizing design, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

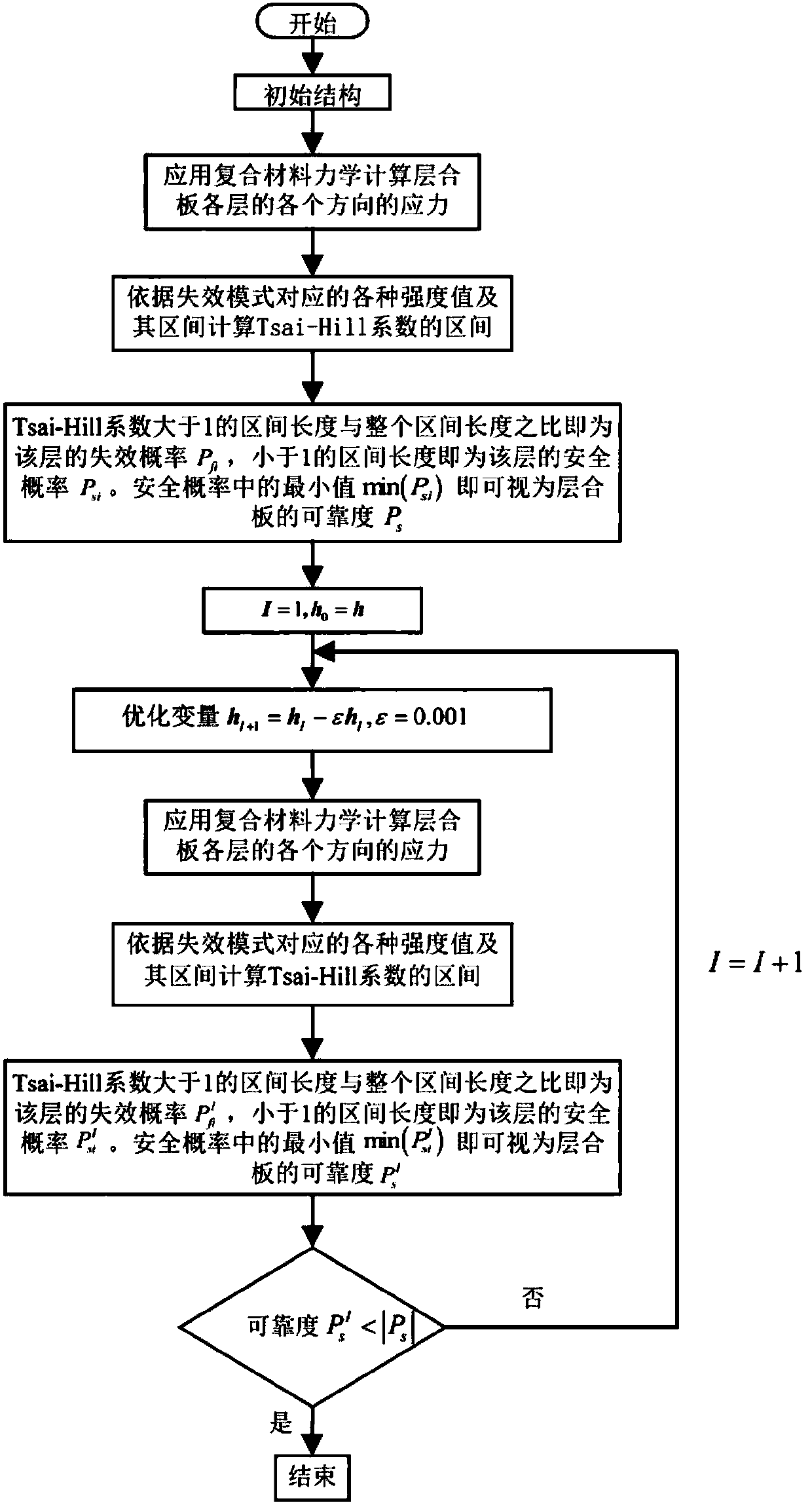

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

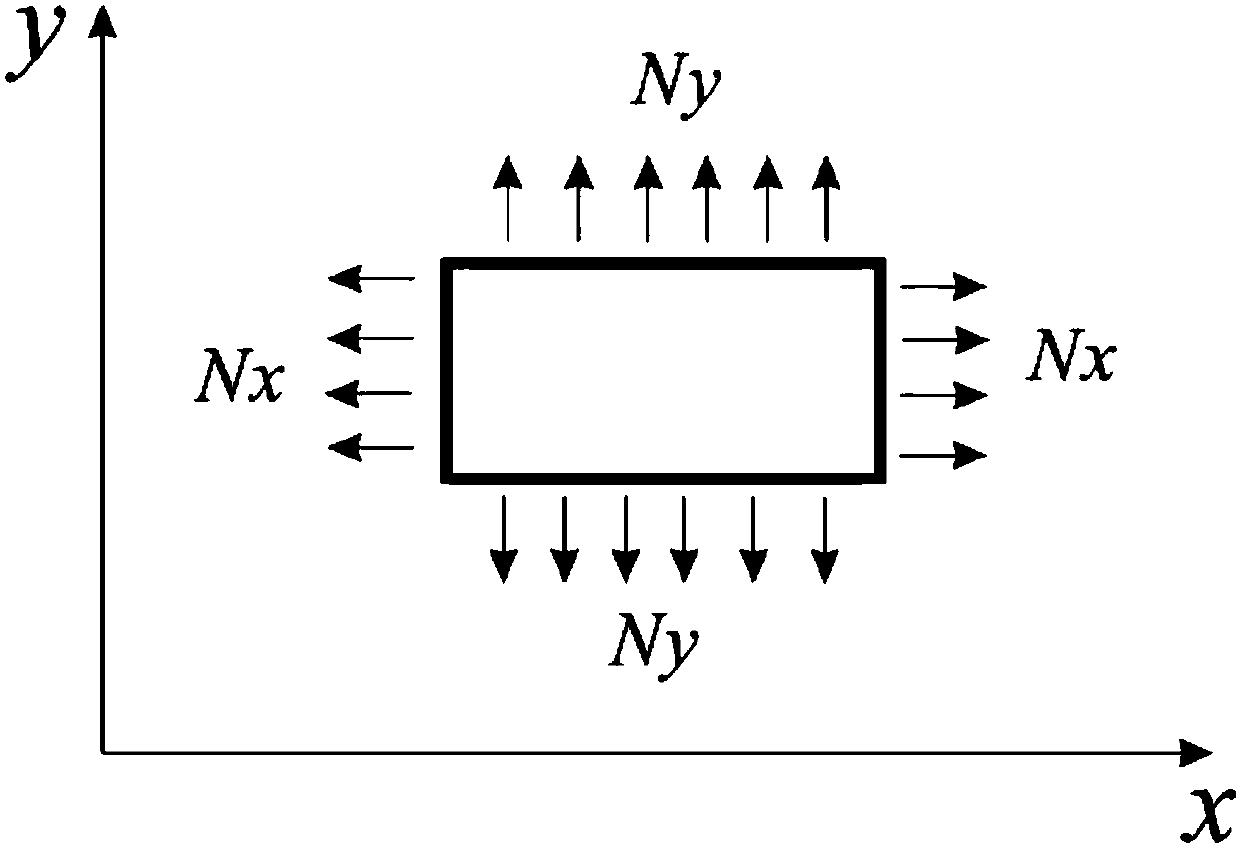

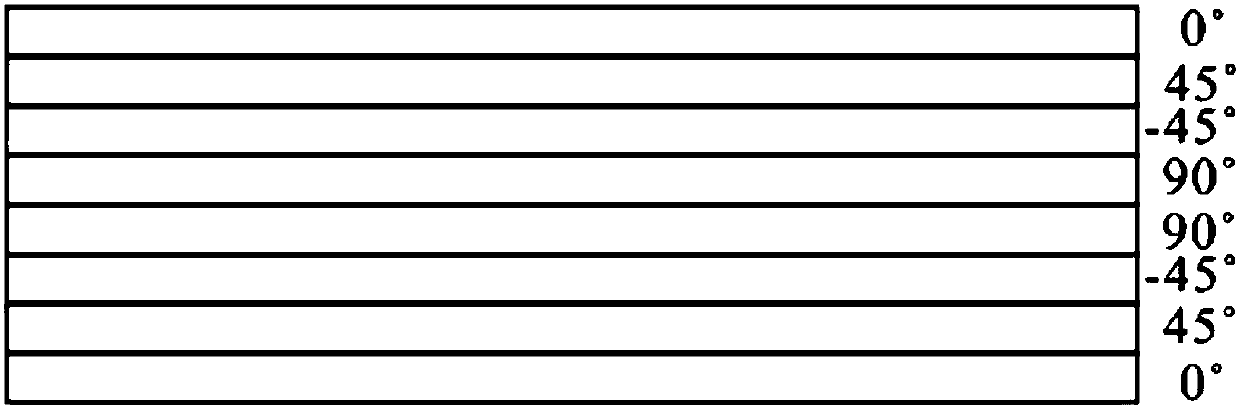

[0051] In order to understand more fully the characteristics of the invention and its applicability to engineering practice, the present invention aims at such as figure 2 In-plane compressive load N x and N y The laminates are optimized based on reliability. Laminate layering method is [0 / 45 / -45 / 90] s ,Such as image 3 . The in-plane dimension of the laminate is a×b=(20*12.5)cm 2 , the thickness of the single-layer board is 0.125mm, so the total thickness of the laminated board is 0.125mm×8=1mm. The table gives the uncertainty information of the rectangular plate structure in the examples. The elastic constants and load parameters of the single-layer plate are as follows:

[0052] E. 1 =181.0GPa,E 2 =10.8GPa,G 12 =7.17Gpa, υ=0.28, N x =400kN / m, N y =72kN / m

[0053] Table 1

[0054]

[0055] This embodiment employs, reliability applications such as Figure 4 The strength reliability of the shown Tsai-Hill interval is obtained. The shaded area in the figure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com