Heat dissipation assembly of air conditioner outdoor unit and air conditioner outdoor unit

An air conditioner outdoor unit and heat dissipation component technology, which is applied in air conditioning systems, space heating and ventilation, household heating, etc., can solve the problems of volume change, increase the complexity of pipeline design, and complex structure of air conditioner outdoor units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

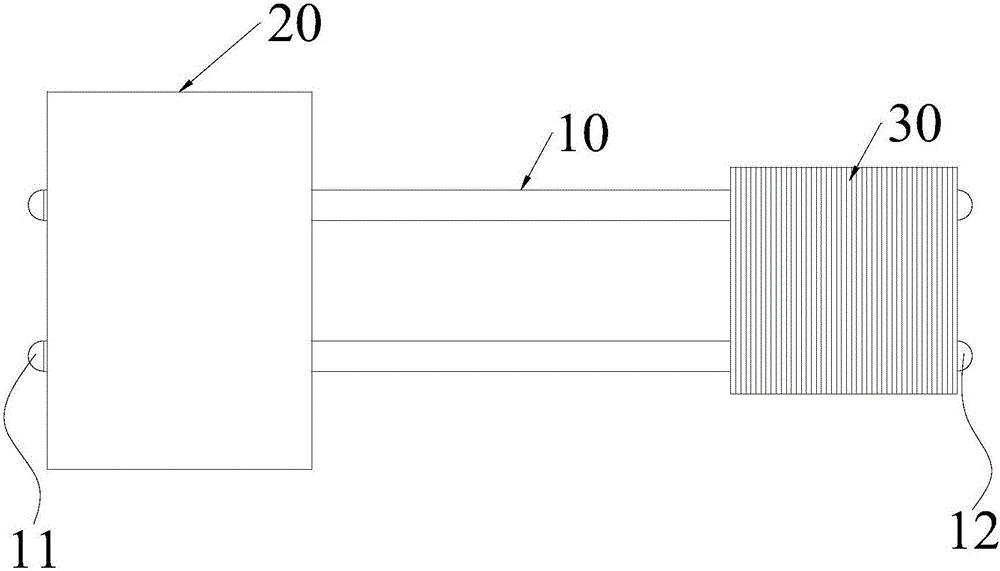

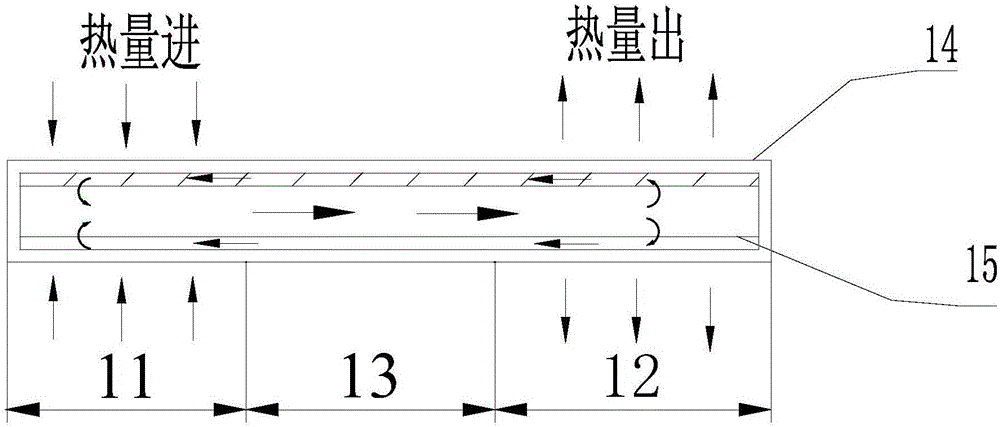

[0017] see figure 1 and figure 2 As shown, according to the embodiment of the present invention, a heat dissipation assembly of an outdoor unit of an air conditioner is provided. The heat dissipation assembly includes a heat pipe 10, one end of the heat pipe 10 is an evaporation section 11, and the other end is a condensation section 12. The evaporation section 11 of the heat pipe 10 is Corresponding to the heating components of the outdoor unit of the air conditioner (it can be arranged directly in contact with the heating components, or exchange heat with the heating components through other structures), the condensation section 12 of the heat pipe 10 is arranged at the heat dissipation part of the outdoor unit of the air conditioner, and the heat pipe The condensing section 12 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com