Real-time positioning clamping type universal support mechanical fixture

A real-time positioning and clamping technology, which is applied to supporting machines, mechanical equipment, machines/stands, etc., can solve the problems of inability to adjust the angle, low machining accuracy, and simple clamping machinery, so as to increase interchangeability, Good portability, the effect of solving positioning and support problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

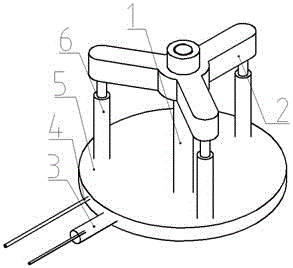

[0017] A mechanical fixture for real-time positioning and clamping universal support, comprising a main support column 1, a single-head three-arm support frame 2, a positive electrode terminal 3, a negative electrode terminal 4, a liquid mixing plate 5, and an electrorheological fluid telescopic rod 6. The main support column 1 is installed at the center of the liquid mixing plate 5 through threaded connection, and the top of the main support column 1 is a spherical head; the electrorheological fluid telescopic rods 6 are arranged in a 120° circular array, and the electrorheological fluid telescopic rods 6 are arranged by the cylinder body, piston rod, piston, and electrorheological fluid filled with the cylinder body, the cylinder body is installed on the liquid mixing plate 5 through threaded connection, and the top of the piston rod is a spherical head; The three spherical holes of 2 are assembled together, and the spherical hole in the middle of the single-head three-arm su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com