Hydraulic valve dedicated to windlass

A hydraulic valve and windlass technology, applied in the field of hydraulic valves, can solve the problems of affecting the surrounding working environment, easy oil leakage at the joints, scattered installation of components, etc., and achieves the effects of complete functions, low production costs, and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

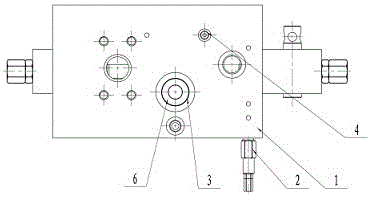

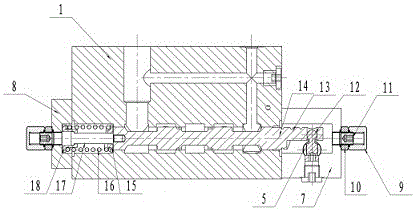

[0014] like figure 1 and figure 2 As shown, this specific embodiment adopts the following technical solutions: a special hydraulic valve for windlass, including a main valve body 1, a relief valve 2, a diverter valve core 3, a shuttle valve 4, an operating shaft 5, a spring 6, an end cover 17, end cover 2 8, cap nut 9, nut 10, limit screw 11, ball pin 12, valve core 13, connecting rod 14, spring seat 15, spring 2 16, pull rod 17 and spring seat 2 18 ; The main valve body 1 is provided with a relief valve 2, a shuttle valve 4, a diverter valve core 3 and a spring 6; the end cover 1 7 is fixedly connected to the lower right side of the main valve body 1; the end cover 2 8 is fixedly connected to the lower left side of the main valve body 1; there are two limit screw rods 11, and the limit screw rods 11 are fixedly connected to the outer sides of end cap one 7 and end cap two 8 through cap nut 9 and nut 10 respectively Central; the spool 13 is movably connected inside the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com