High-performance metal hard sealing butterfly valve

A metal sealing ring and hard sealing technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of inseparability, increased maintenance costs, waste of resources, etc., to reduce maintenance man-hours and maintenance intensity and difficulty, reduce Maintenance cost, eliminate the effect of impervious to erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

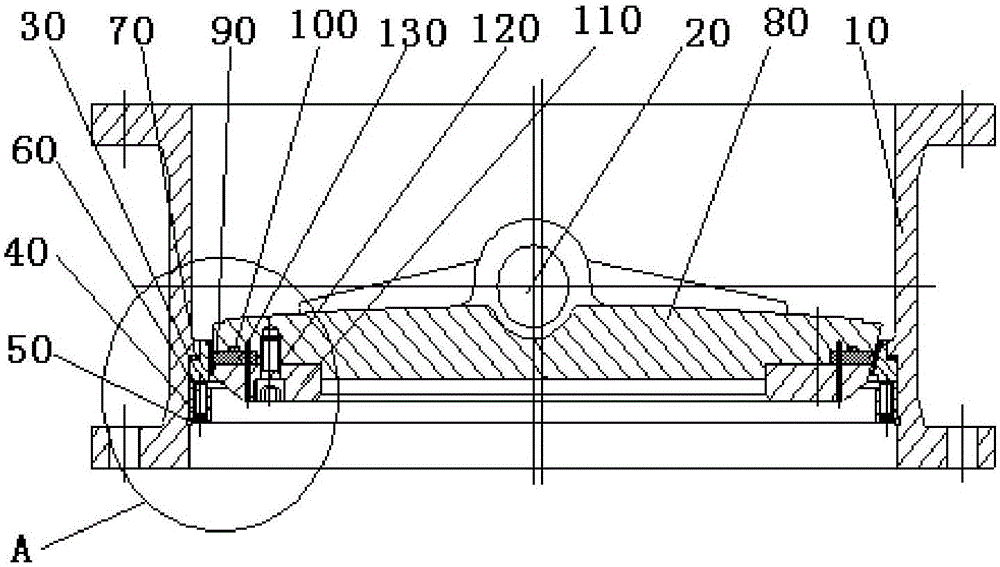

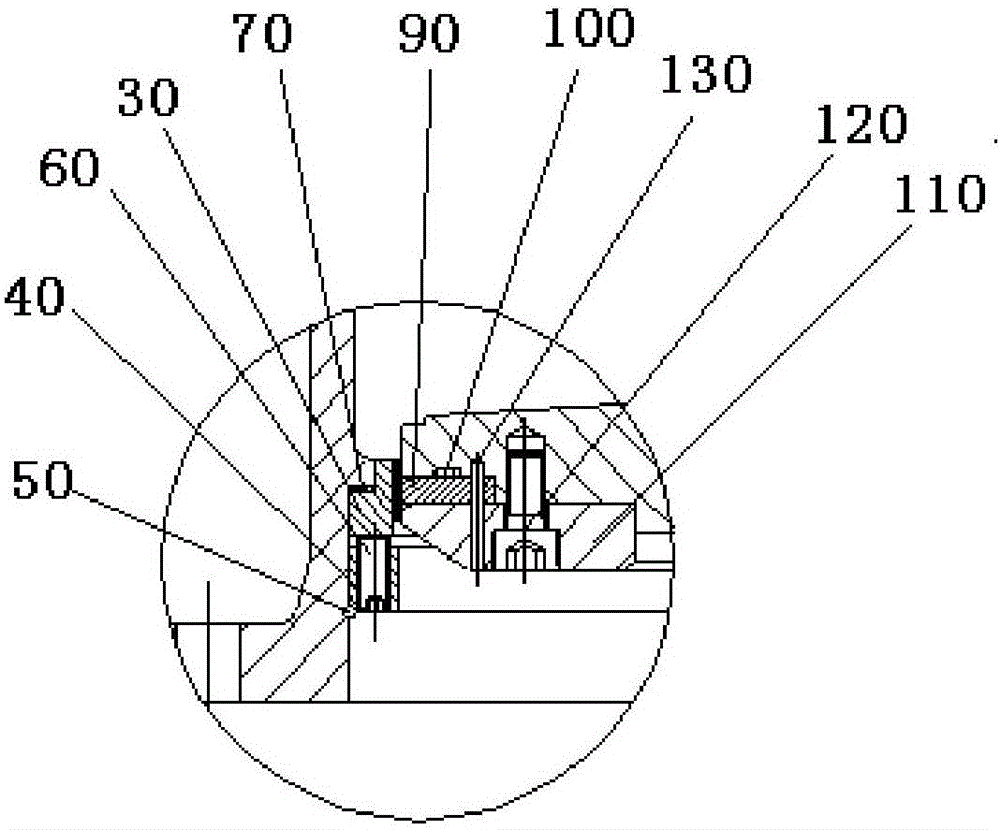

[0020] see figure 1 with figure 2 As shown, the present invention discloses a high-performance metal hard-sealed butterfly valve, including a valve body 10, a butterfly plate assembly, a valve stem 20, a valve seat 30, a valve seat pressure plate 40 and a retaining ring 50; the valve seat 30 passes through the valve seat pressure plate 40 and the hexagon socket flat-end set screw 60 are fixed on the inner wall of the valve, and a metal gasket 70 is arranged between the valve seat 30 and the adjacent plane of the valve body 10 to play a sealing role; at the same time, by adjusting the thickness of the metal gasket , to ensure the sealing specific pressure between the sealing surfaces, so as to effectively ensure the bidirectional sealing of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com