Stator combined structure of cooling fan

A combined structure and fan stator technology, applied in the direction of magnetic circuit shape/style/structure, electric components, casing/cover/support, etc., can solve the problems of easy loosening, manufacturing and processing, high difficulty in assembly and positioning, and bonding strength Insufficient and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

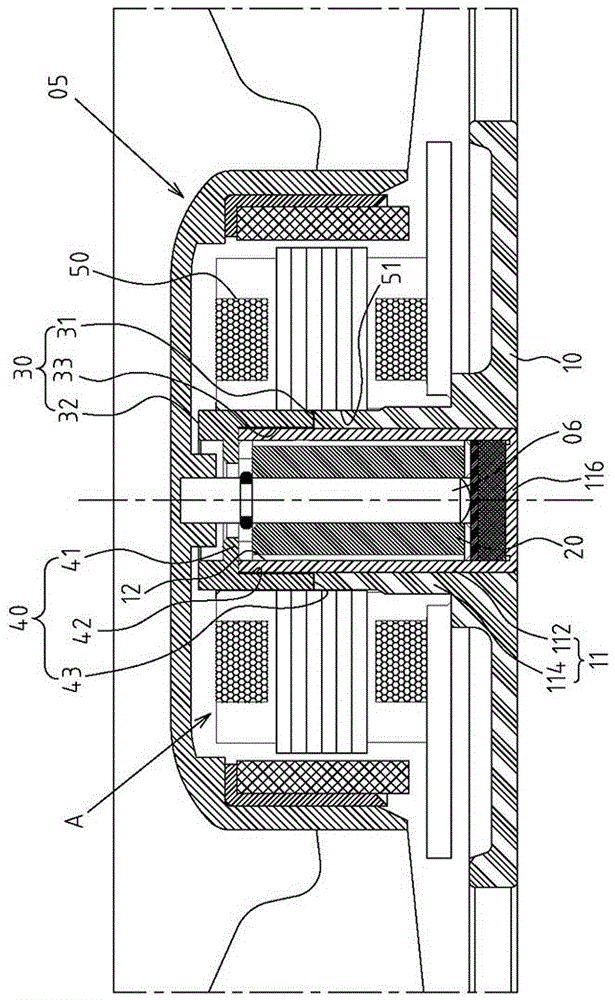

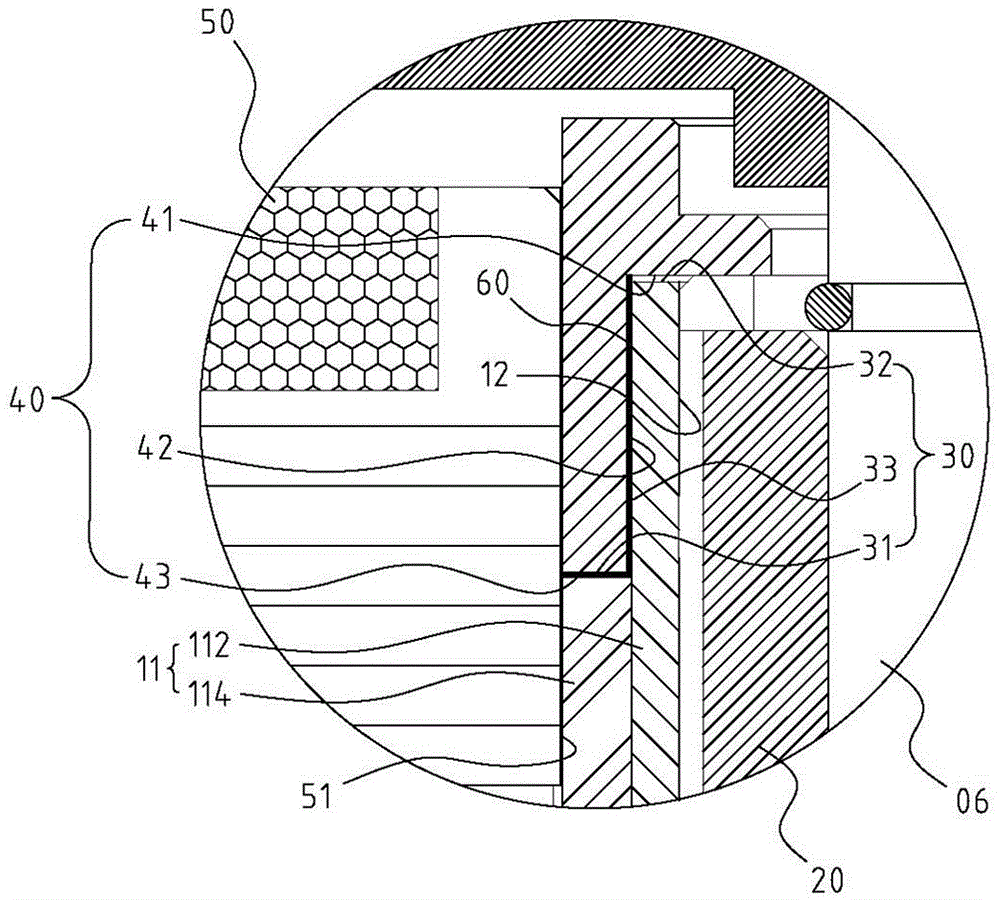

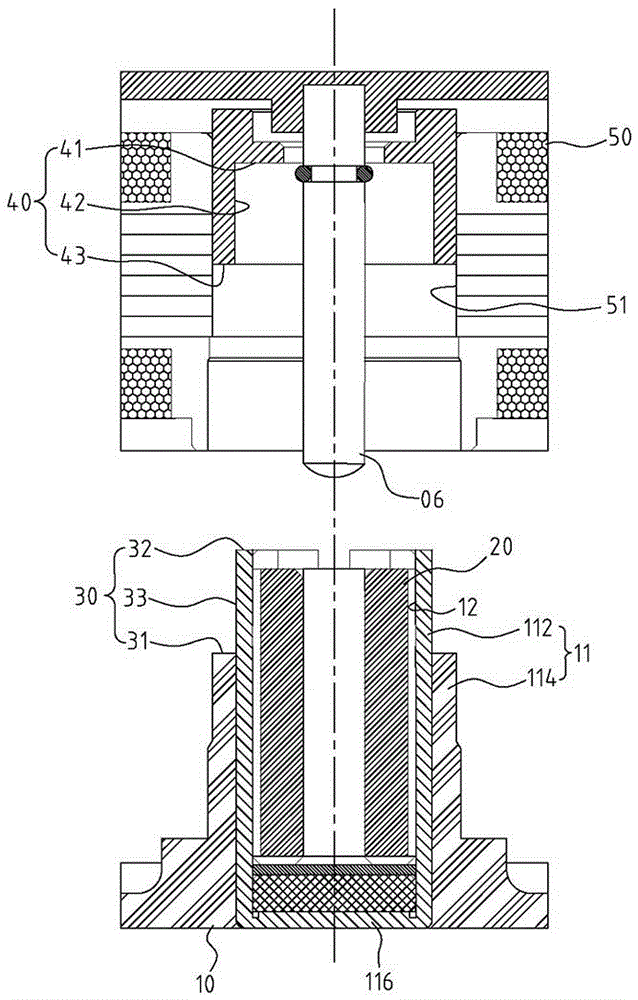

[0026] Example: see Figure 1~3 Shown are the preferred embodiments of the cooling fan stator combination structure of the present invention, but these embodiments are for illustration purposes only, and are not limited by this structure in patent application.

[0027] The stator A of the cooling fan is used for the rotor 05 shaft center 06 pivot group of the cooling fan (such as figure 1 shown), the combined structure of the cooling fan stator A includes:

[0028] A base 10, the center of which is protrudingly provided with a shaft receiving part 11, and a receiving groove 12 is formed inside the shaft receiving part 11;

[0029] A bearing 20 is assembled in the accommodating groove 12 of the shaft receiving part 11;

[0030] A step-shaped joint positioning portion 30 is formed at the end of the shaft receiving portion 11. The step-shaped joint positioning portion 30 includes a first axial surface 31 and a second axial surface with an axial step difference. 32 and a radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com