Steel frame template anti-displacement apparatus

A technology of displacement device and formwork, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of easy displacement of panels, large section size of wall columns, etc., and achieves easy construction and turnover. The effect of high rate and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

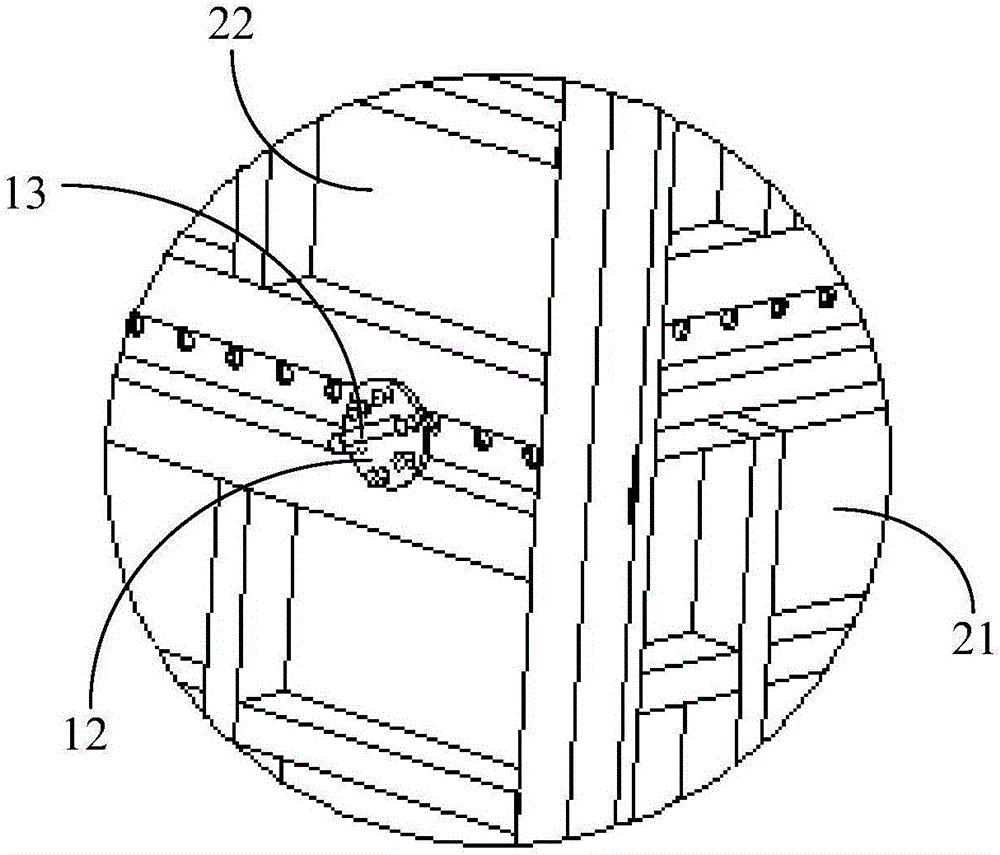

[0021] First, see figure 1 As shown, the anti-displacement device of the steel frame formwork of the present invention is mainly composed of a positioning clamp 11, a tie rod body 12 and an imprisoning piece 13. The height of the steel frame formwork is large enough to ensure that the wall column structure is smooth. However, the general use The clamp parts cannot guarantee the fit and bite force between the side forms of the steel frame formwork, and the parts are easy to loosen after multiple turnovers, and the side forms are easy to shift during pouring concrete, resulting in a large section size. The anti-displacement device of the steel frame formwork of the present invention is simple in structure, easy to disassemble and assemble, easy to obtain materials, and has a high turnover rate. figure 2 As shown, between the first sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com