Punched rib and pull rod constraint double-layer steel plate concrete shear wall

A steel plate concrete and shear wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of weak out-of-plane deformation capacity of stiffener restraints, weak lateral restraint force, tensile connection, and stiffness ratio of large rib plates. The effect of improving the lateral restraint capacity, strengthening the integrity, improving the bearing capacity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

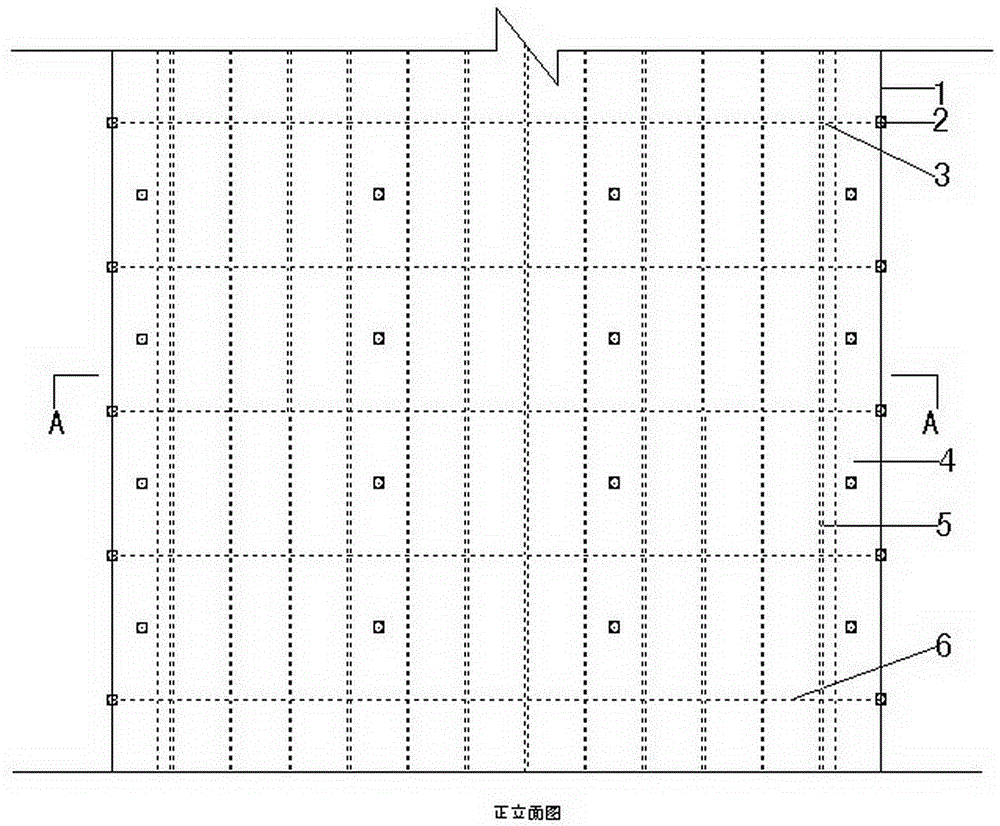

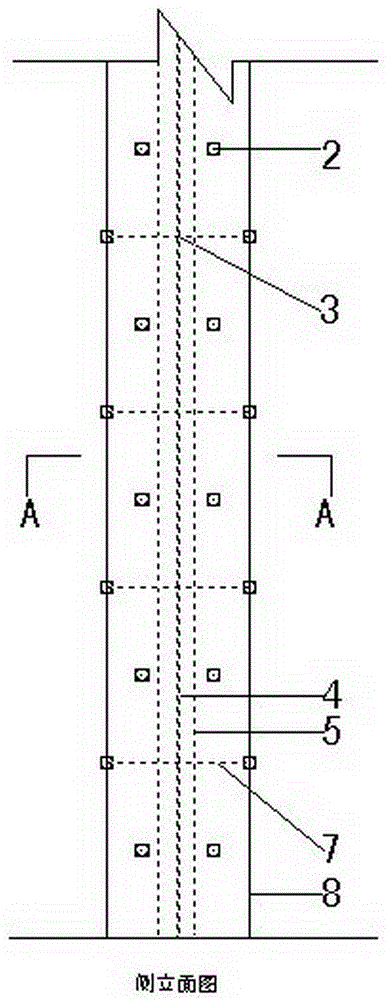

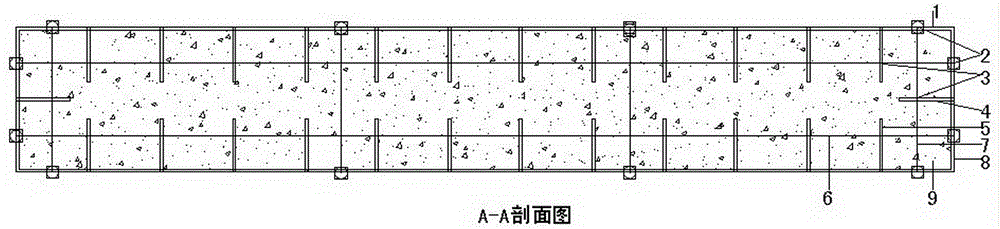

[0023] The manufacturing steps of a double-layer steel plate concrete shear wall constrained by perforated rib tie rods are as follows:

[0024] (1) According to the requirements of the design drawings, determine the strength, size, Location;

[0025] (2) Make the steel plates on both sides of the double-layer steel plate concrete shear wall, connecting steel plates, stiffeners, and tie rods;

[0026] (3) Measure the layout position of the positioning tie rods, and drill holes at the positions where the double-layer steel plate tie rods pass through in the double-layer steel plate concrete shear wall;

[0027] (4) Use the welding method to weld the opening stiffeners to the steel plates on both sides and the connecting steel plates;

[0028] (5) Install the tie rods 7 along the wall thickness direction at both ends of the wall through the stiffeners 4 set along the wall thickness direction and install them in the drilled holes of the steel plates on both sides of the wall, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com