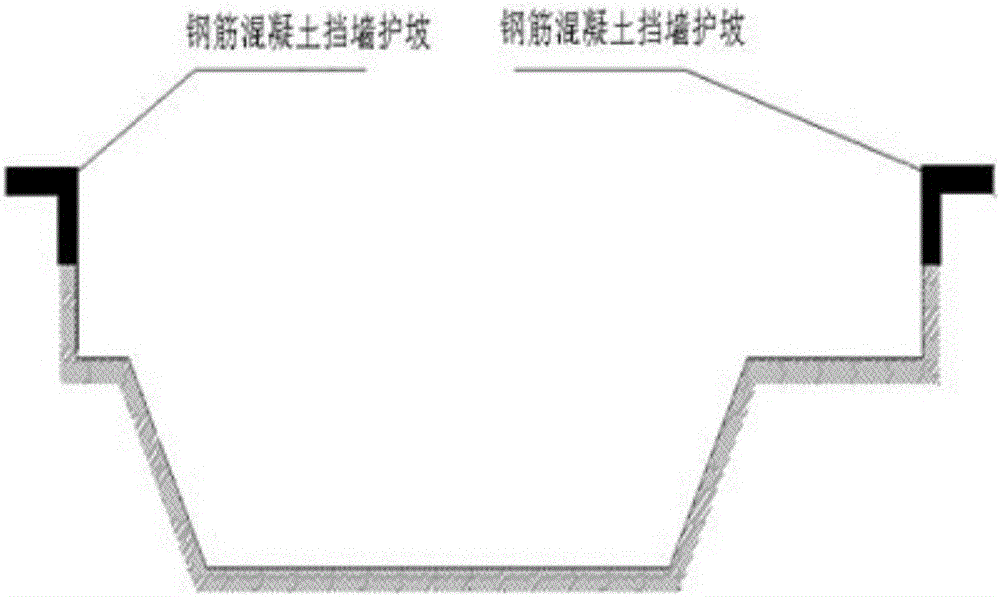

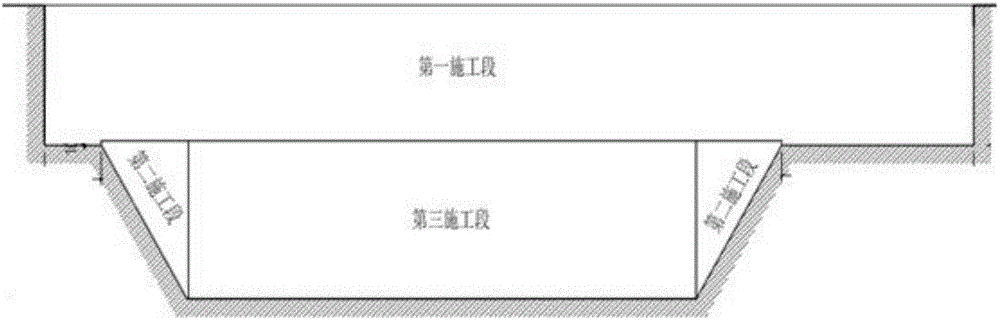

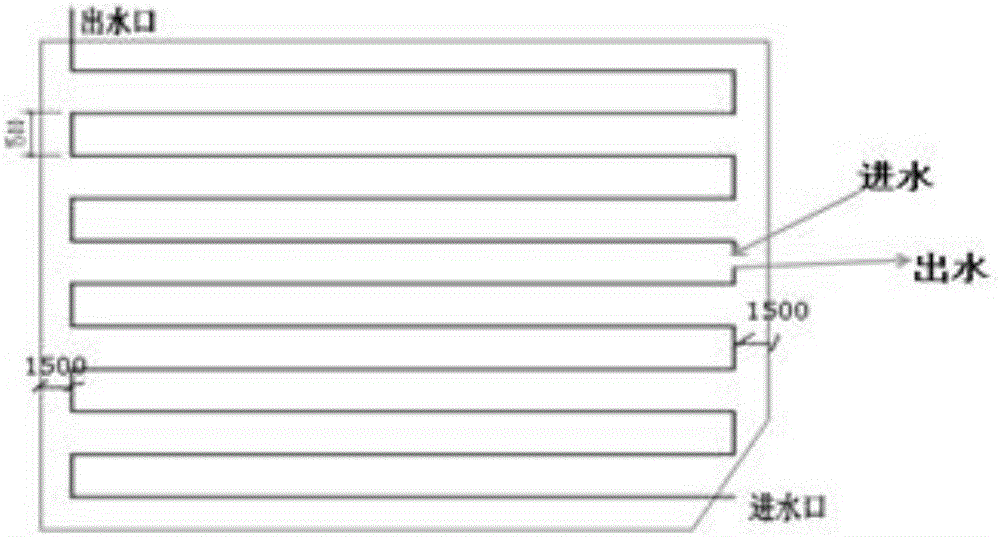

Stepped large raft construction technology

A construction technique and raft technology, which is applied in basic structure engineering, construction, etc., can solve problems such as temperature difference control between inside and outside of concrete, difficult maintenance quality, temperature cracks and mold explosion, etc., to reduce secondary erection, construction safety, and energy saving labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The No. 4 and No. 5 buildings of the third group of the Chongqing Longhu Guanyin Bridge Project are located in the Yaoziqiu area on the south side of the Hongqihegou turntable in Jiangbei District, Chongqing. They are large-scale high-rise commercial and office complex buildings. The standard storey height is 5.1m, and the building area is 13454.51㎡: Building No. 5 has a total height of 176.8m, a standard storey height of 4.2m, and a building area of 52370.32㎡. Partial thickness is 4.2m, concrete volume is about 400m3, steel bar spacing ф22@100; 5# floor raft planar size is 21.3m×17.2m, thickness is 2.5m, local thickness is 7.9m, concrete volume is about 1210m 3 , the steel bar is ф28@100. The reinforcement is HRB400 double-layer two-way reinforcement. During the construction process, large-diameter steel bars and long horse stools were used to fix the steel bars on the upper and lower floors. The elevator shaft formwork support system was used, and full hall bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com