A nanofiber modified ultra-soft nonwoven fabric and its manufacturing method

A technology of nanofibers and non-woven fabrics, applied in the direction of non-woven fabrics, rayon manufacturing, fiber chemical characteristics, etc., can solve discomfort and other problems, achieve the effect of increasing specific surface area, enhancing softness, smooth and plump hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

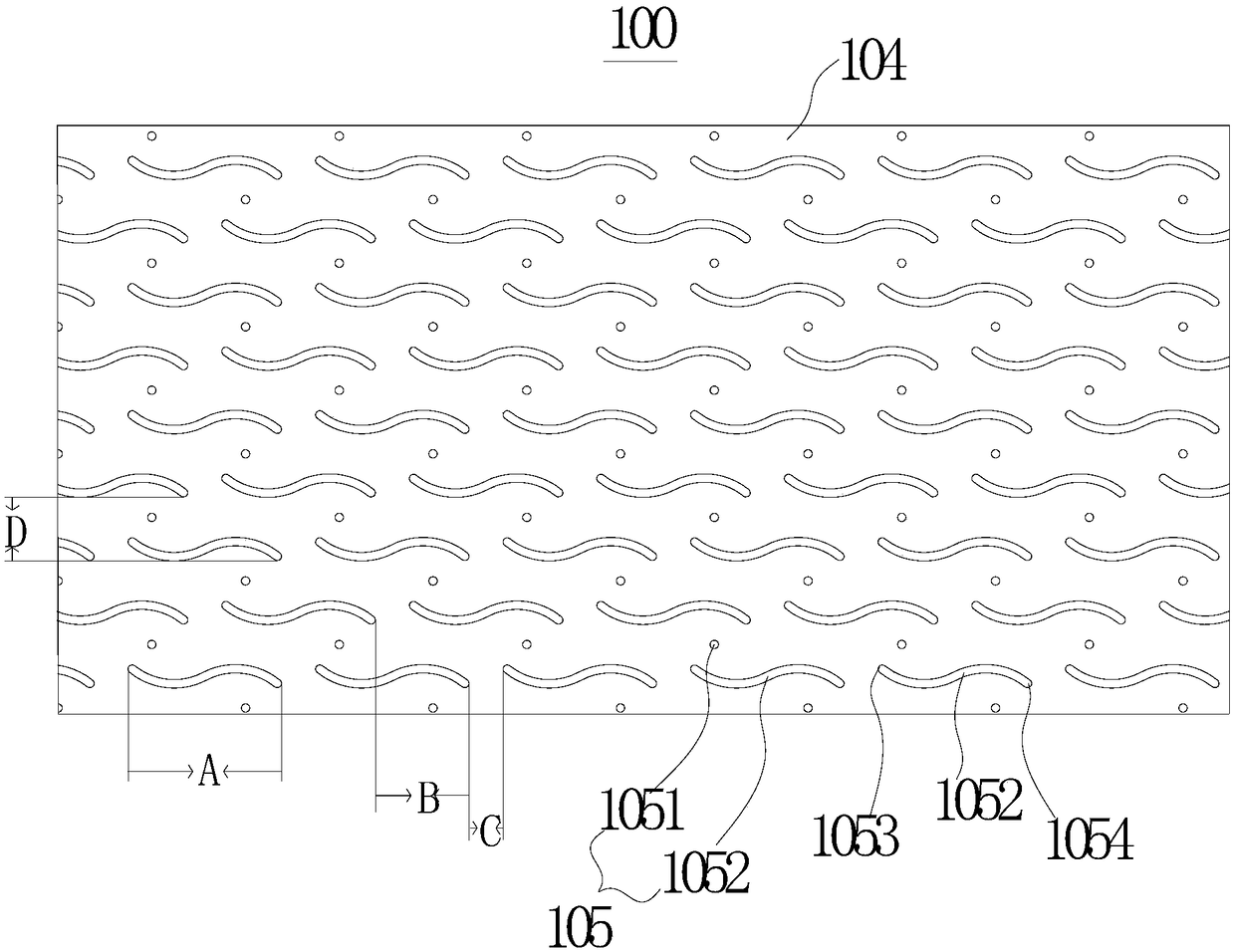

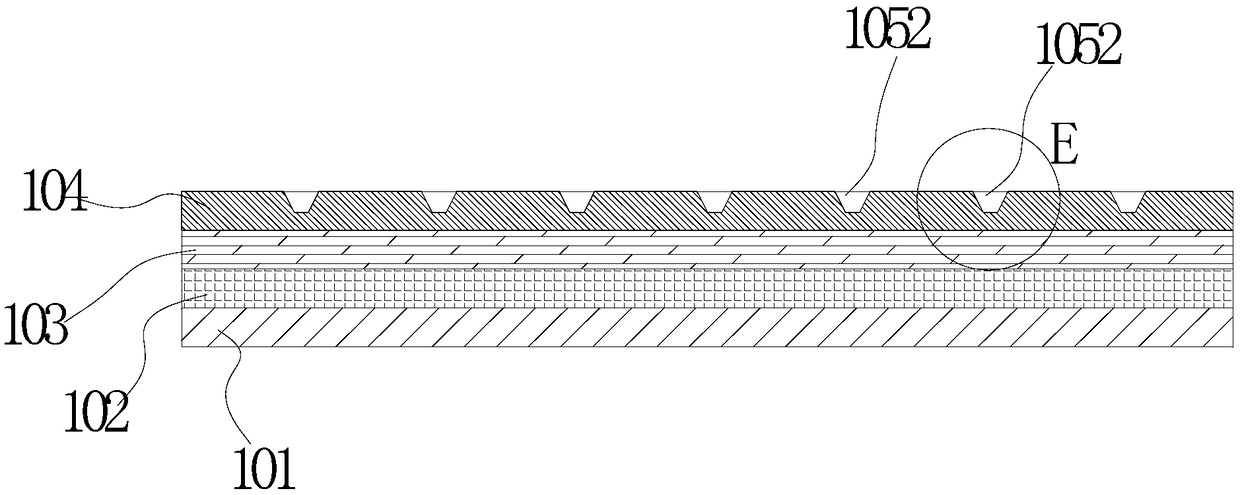

[0028] see Figure 1 ~ Figure 3 , the nanofiber modified ultra-soft nonwoven fabric 100 provided in this embodiment includes a base layer 101 laminated sequentially from bottom to top, a hydrophilic layer 102 attached to the base layer 101, an antibacterial layer attached to the hydrophilic layer 102 Layer 103, and the nano-modified fiber soft layer 104 made of polypropylene, nano-elastomer, and soft masterbatch mixed with the antibacterial layer 103, melted, spun, and composite non-woven technology.

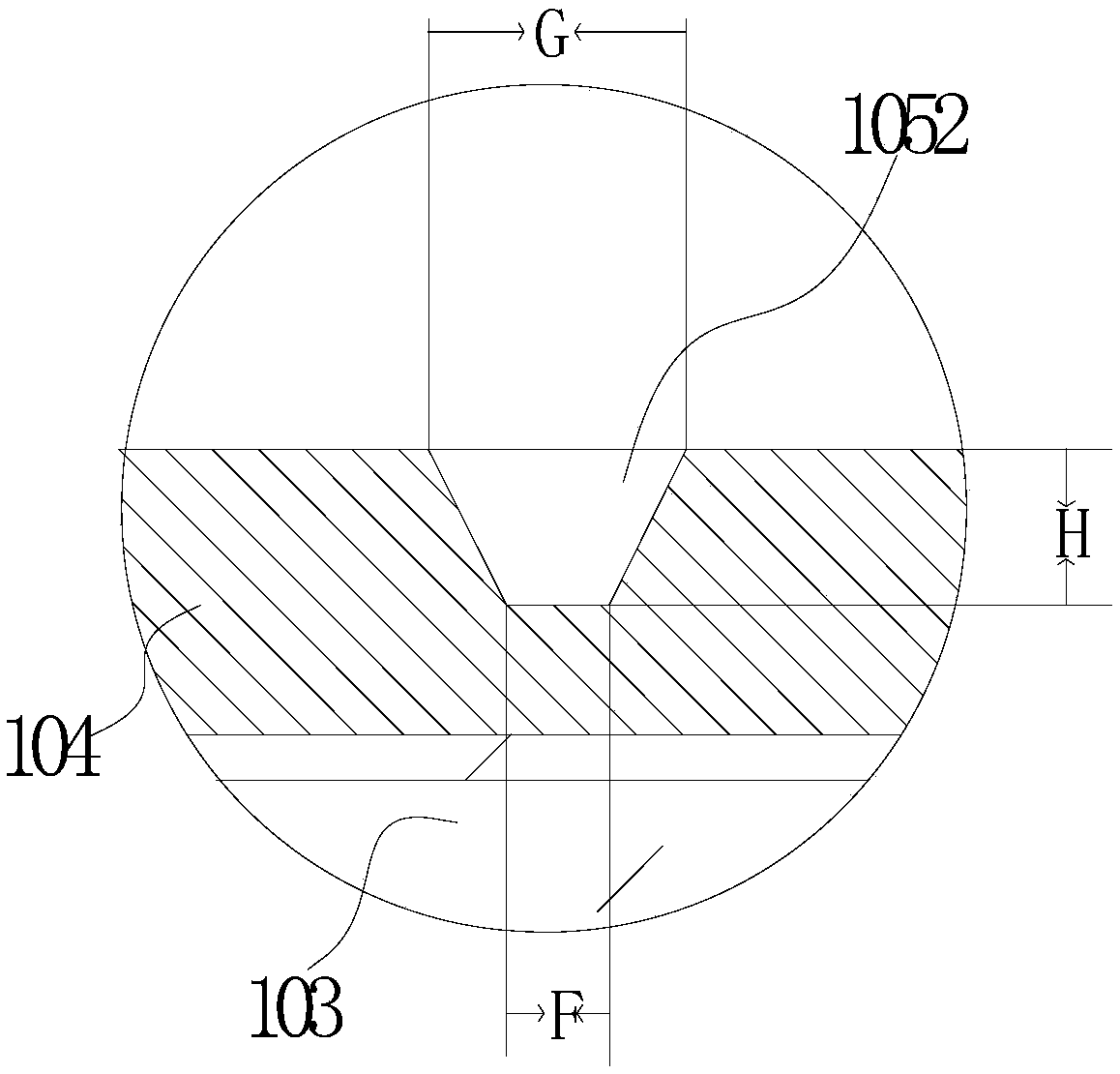

[0029] Wherein, the surface of the nano-modified fiber soft layer 104 away from the antibacterial layer 103 is provided with a plurality of evenly arranged texture units 105 . Each texture unit 105 includes a first groove 1051 and a second groove 1052, the first groove 1051 is located near the second groove 1052, the cross section of the first groove 1051 is circular, and the second groove 1052 The cross-section is S-shaped.

[0030] In addition, in this embodiment, the soft n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com