Electrolytic etchant and electrolytic etching method for chromium zirconium copper alloys

An etchant, chromium-zirconium-copper technology, applied in the field of electrolytic etchant for chromium-zirconium-copper alloys, can solve problems such as less chromium-zirconium-copper alloys, achieve better bonding, firm bonding, and overcome instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

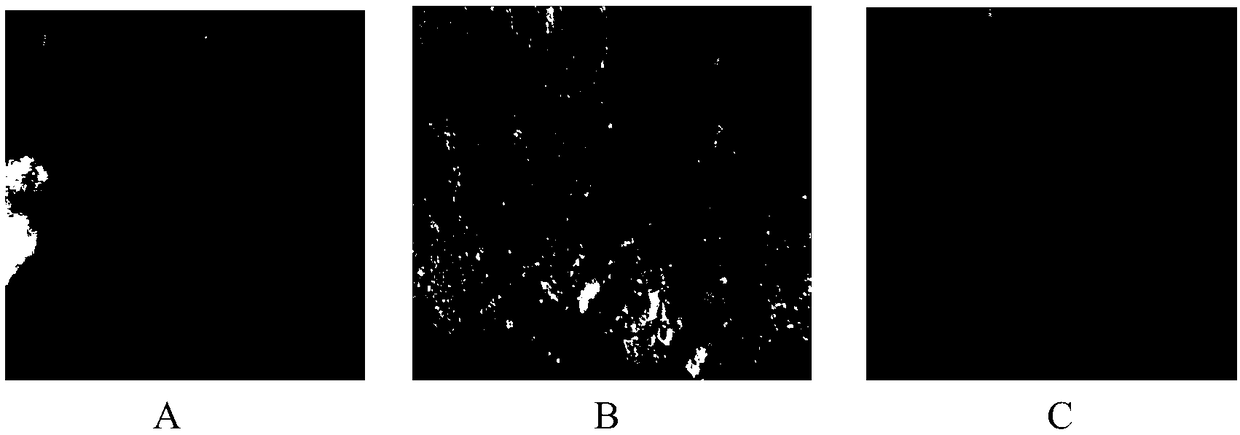

Image

Examples

Embodiment 1

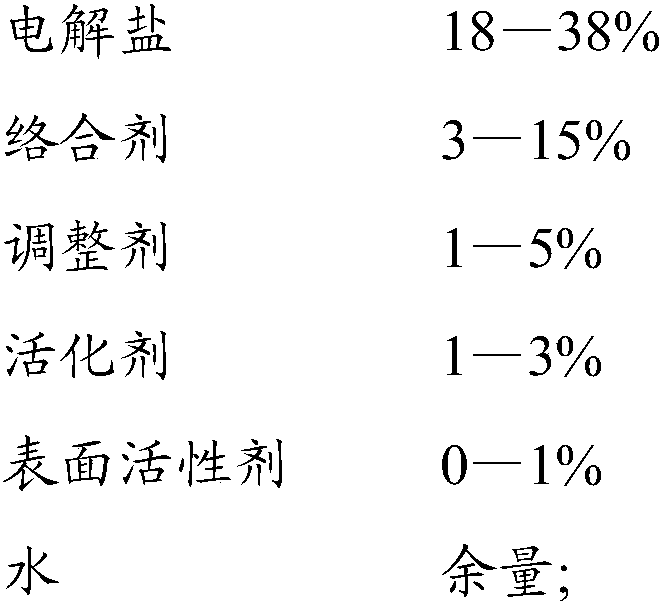

[0038] The chromium-zirconium-copper alloy electrolytic etchant of the present embodiment is made up of the following components by weight percentage:

[0039]

Embodiment 2

[0041] The chromium-zirconium-copper alloy electrolytic etchant of the present embodiment is made up of the following components by weight percentage:

[0042]

[0043]

Embodiment 3

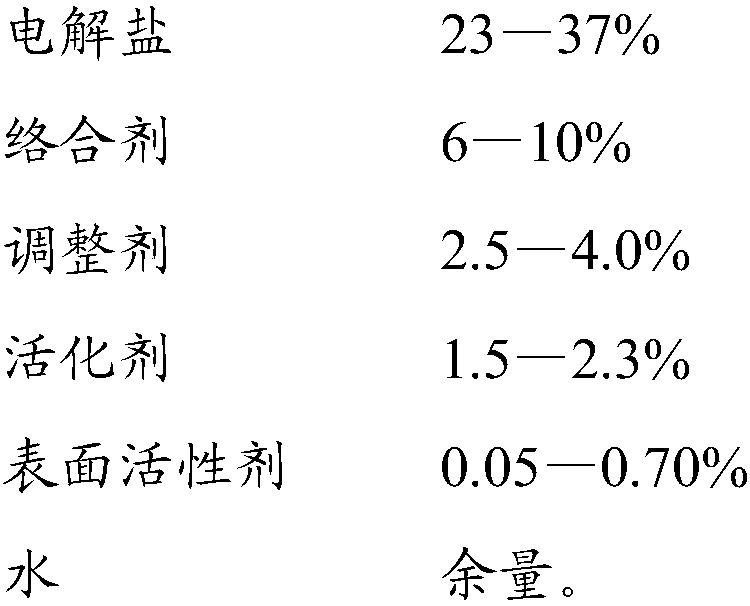

[0045] The chromium-zirconium-copper alloy electrolytic etchant of the present embodiment is made up of the following components by weight percentage:

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com