A kind of integrated recording material and preparation method thereof

A recording material and carrier technology, applied in the direction of reproduction/marking method, printing, etc., can solve the problems of low temperature tolerance and short shelf life, and achieve good environmental tolerance, easy use, good practical value and popularization and application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

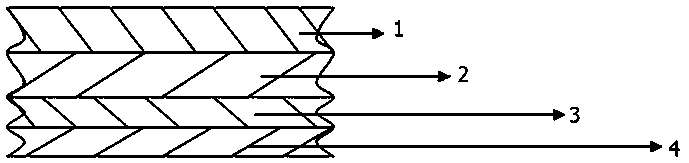

[0034] like figure 1 As shown, the integrated recording material provided by the present invention includes a carrier 4, a thermal sublimation layer 3, an adhesive layer 2, and a color-developing layer 1 arranged sequentially from bottom to top; The dye in the thermal sublimation layer 3 condenses on the color-developing layer 1 after sublimation, so as to realize the recording of information such as characters or patterns.

[0035] Specifically, in the integrated recording material provided in this example, the carrier is a polyester film BOPET (product of DuPont) with a thickness of 20 μm.

[0036] The thermal sublimation ink ratio used in the thermal sublimation layer is, in terms of mass percentage, composed of 50% resin binder rosin glyceride, 20% red dye and 30% filler talcum powder; when used, press methyl ethyl ketone: Resin linking material=5:1 mass ratio, after dissolving the resin linking material, then add dyes and fillers, mix evenly and spread on the flat and sm...

Embodiment 2

[0045] The preparation method of the integrated recording material provided in this example is the same as in Example 1, only the types and proportions of some materials are briefly adjusted, and the specific adjustments are as follows:

[0046] The carrier adopts 80g / m 2 coated paper.

[0047]The sublimation ink ratio used in the sublimation layer is, in terms of mass percentage, composed of 45% resin binder pine hydroxypropyl methylcellulose, 25% blue dye and 30% filler mica powder; , according to the mass ratio of ethanol: resin binder = 5:1, dissolve the resin binder, then add dyes and fillers, mix evenly and spread on the flat and smooth surface of the carrier, the coating amount is 4.0g / m 2 ; 90 ℃ coating after drying is the thermal sublimation layer.

[0048] Described bonding layer, by mass percentage, bonding ink component is the EVA resin (EVAFLEX 210) of 60% and the paraffin of 40%; After dissolving, add paraffin and mix evenly, mix evenly and apply on the surfac...

Embodiment 3

[0052] The preparation method of the integrated recording material provided in this example is the same as in Example 1, only the types and proportions of some materials are briefly adjusted, and the specific adjustments are as follows:

[0053] The carrier adopts 100g / m2 made of aluminum foil and raw paper 2 Composite paper.

[0054] The ratio of sublimation ink used in the sublimation layer is, in terms of mass percentage, composed of 60% resin binder polyphenylene ether resin, 20% yellow dye and 20% filler talcum powder; : Resin linking material = 5:1 mass ratio, after dissolving the resin linking material, add dyes and fillers, mix evenly and spread on the flat and smooth surface of the carrier, the coating amount is 3.0g / m 2 , drying at 80°C after coating is the thermal sublimation layer;

[0055] The bonding layer, in terms of mass percentage, the bonding ink component is 50% EVA resin (EVAFLEX 210) and 50% beeswax; when in use, press toluene: EVA resin = 5: 1 mass rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com