Printing method and printing mechanism for simultaneous digital jet printing and rotary screen printing

A digital jet printing and rotary screen printing technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of short printing and dyeing cycle and complex patterns, and achieve the effect of ensuring accurate overprinting and realizing accurate overprinting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0033] Example.

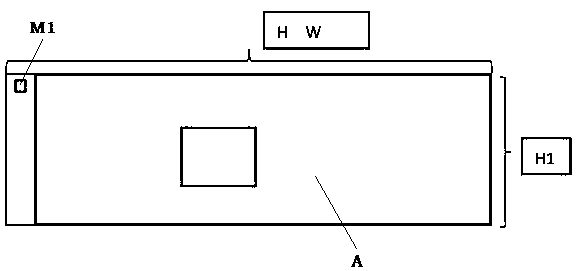

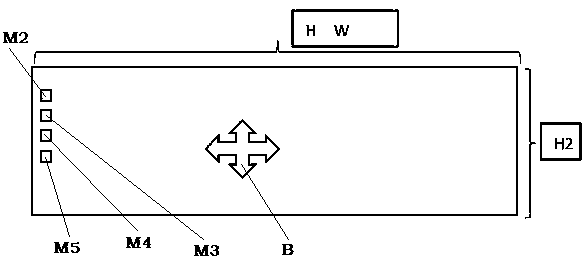

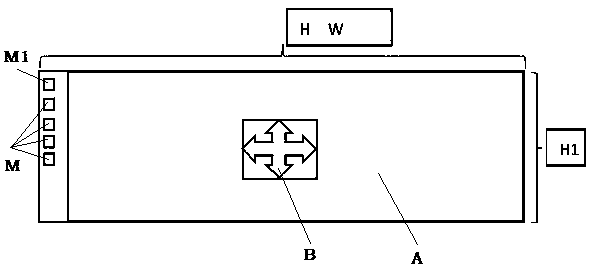

[0034] see Figure 1 to Figure 6 In this embodiment, the steps of the printing method in which digital jet printing and rotary screen printing are synchronized are as follows.

[0035] (1) Use the rotary screen 3 prepared with a flower pattern and at least one anti-flower mark to perform printing operation on the fabric to be printed, so that the corresponding screen printing pattern A and the corresponding anti-flower mark point M1 are formed on the to-be-printed fabric .

[0036] (2) Use the front camera 1 to take pictures of the length between two adjacent paired mark points M1 on the printed fabric to determine the actual size of the circular screen 3 between the two adjacent paired mark poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com