A broadband soundproof honeycomb panel

A honeycomb panel and broadband technology, applied in the field of broadband sound insulation honeycomb panels, can solve the problems of reduced sound insulation performance and difficulty in dealing with low-frequency noise, and achieve the effect of widening the sound absorption band, reducing the weight of the product, and meeting the requirements of light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

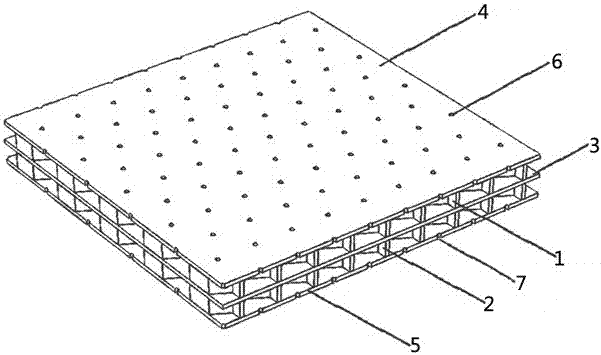

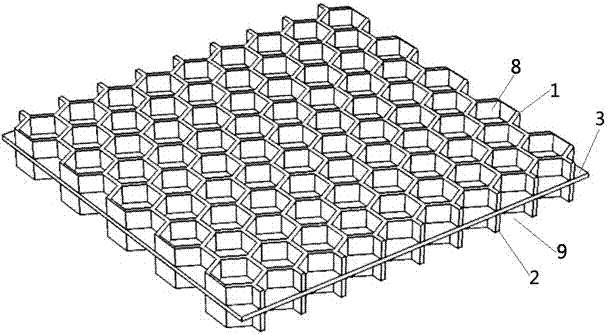

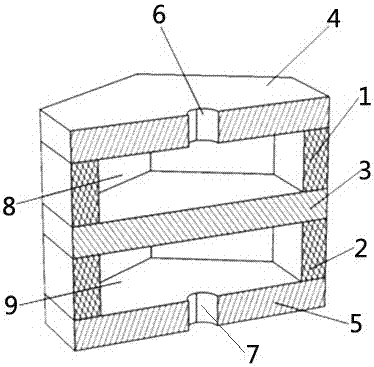

[0028] Such as figure 1 and figure 2 The broadband sound-insulating honeycomb panel shown is formed by bonding the first orifice plate 4, the first honeycomb core 1, the elastic film 3, the second honeycomb core 2, and the second orifice plate 5 in sequence. A number of first cavities 8 are distributed, a number of second cavities 9 corresponding to the first cavities 8 are distributed on the second honeycomb core 2, and a number of second cavities 9 corresponding to the first cavities 8 are distributed on the first orifice plate 4. The first micro-perforations 6 communicate with each other, and the second micro-perforations 7 communicating with the second cavity 9 are distributed on the second orifice plate 5 . Since the first cavity 8 and the second cavity 9 correspond one-to-one, the first honeycomb core 1 and the second honeycomb core 2 divide the elastic film 3 into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com