Edge banding and film sticking device of plastic cloth

A film sticking device and adhesive tape technology, applied to cardboard items, etc., can solve the problems of tearing, shoddy, low efficiency, etc., and achieve the effects of increasing waterproof, high use efficiency, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be further described in detail below.

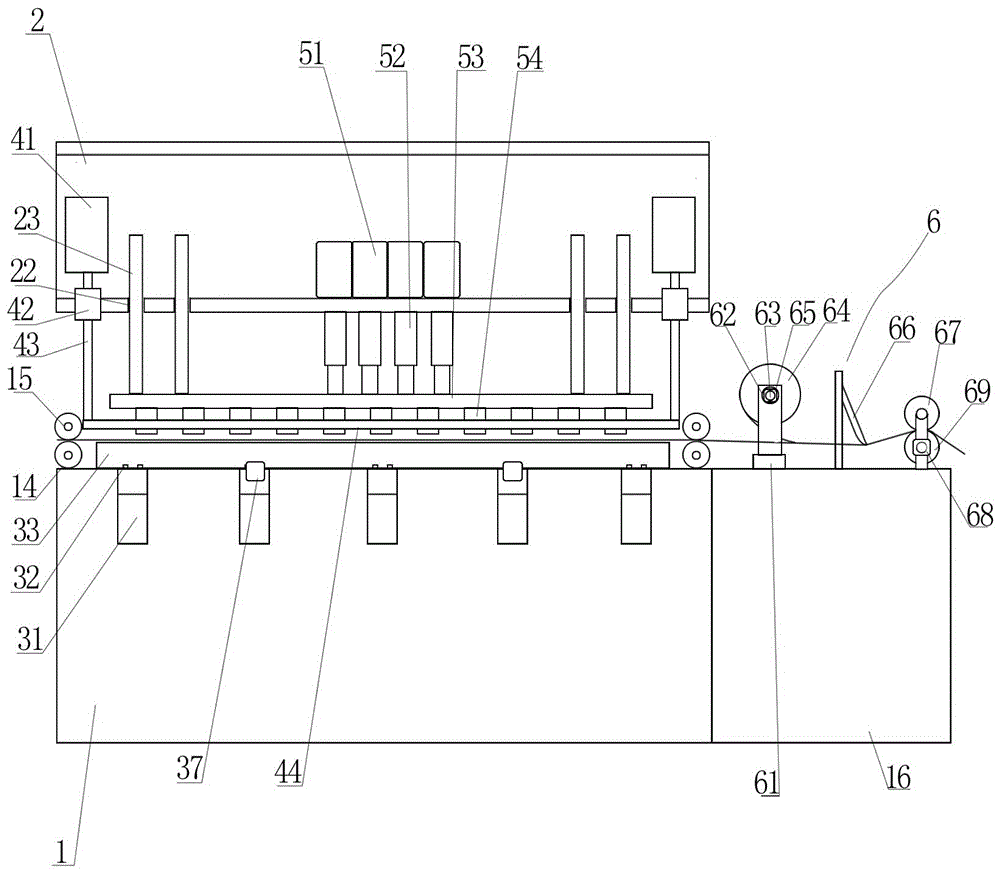

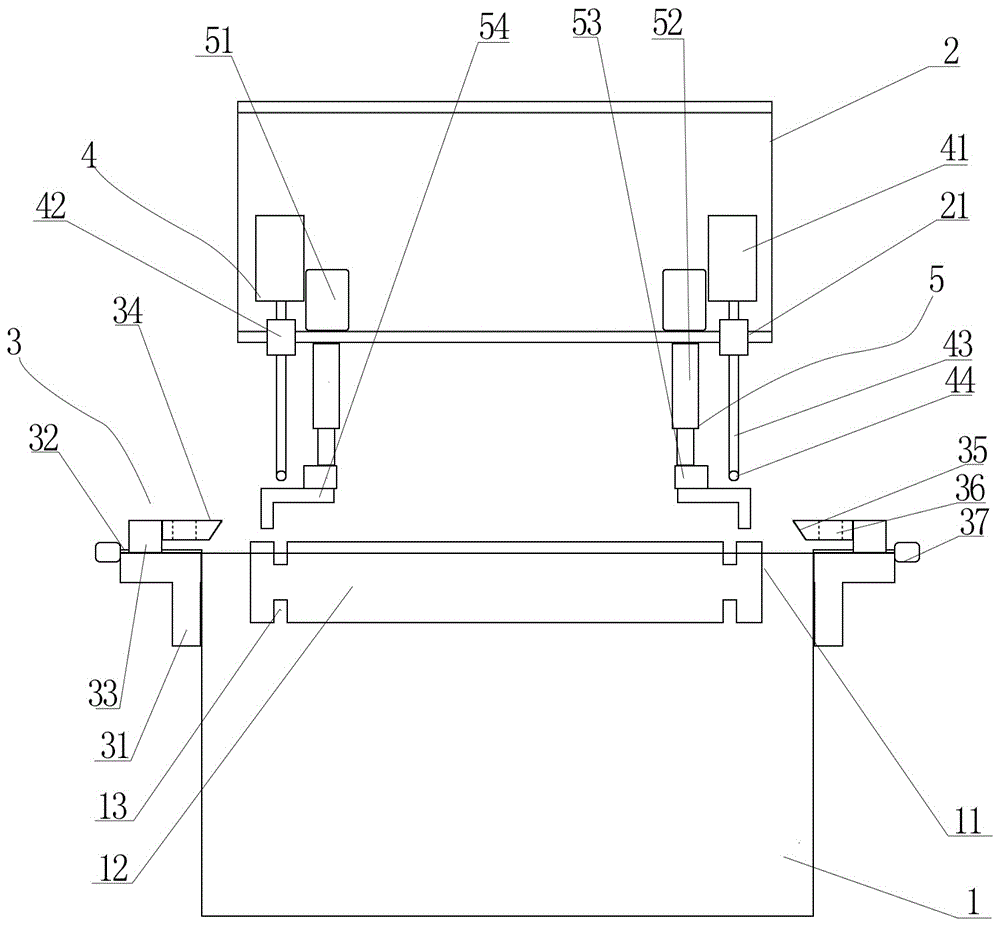

[0015] Such as figure 1 and figure 2 As shown, a plastic cloth edge sealing and film sticking device of the present invention includes a hollow lower frame 1 and an upper frame 2 arranged above the lower frame 1, and is characterized in that: the top of the lower frame 1 is provided with a rectangular Opening 11, a conveyor 12 is arranged horizontally in the opening 11, the conveyor 12 is higher than the top of the lower frame 1, a circle of grooves 13 are respectively provided inwardly on both sides of the conveyor 12, and folds are arranged on both sides of the lower frame 1. The bending assembly 3, the upper frame 2 are respectively provided with an extrusion assembly 4 and an edge sealing assembly 5, and the four corners of the bottom of the upper frame 2 are respectively provided with first concave holes 21, and the extrusion assembly 4 includes four first concave holes 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com