Movable electric welding machine good in cooling performance

A heat dissipation performance and welding machine technology, applied in the direction of electrical components, welding accessories, electrical equipment structural parts, etc., can solve the problems of inconvenient movement of the welding machine, inability to dissipate heat in time, and shorten the service life of the welding machine, so as to reduce heat , keep clean, reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] as attached figure 1 to attach Figure 4 shown

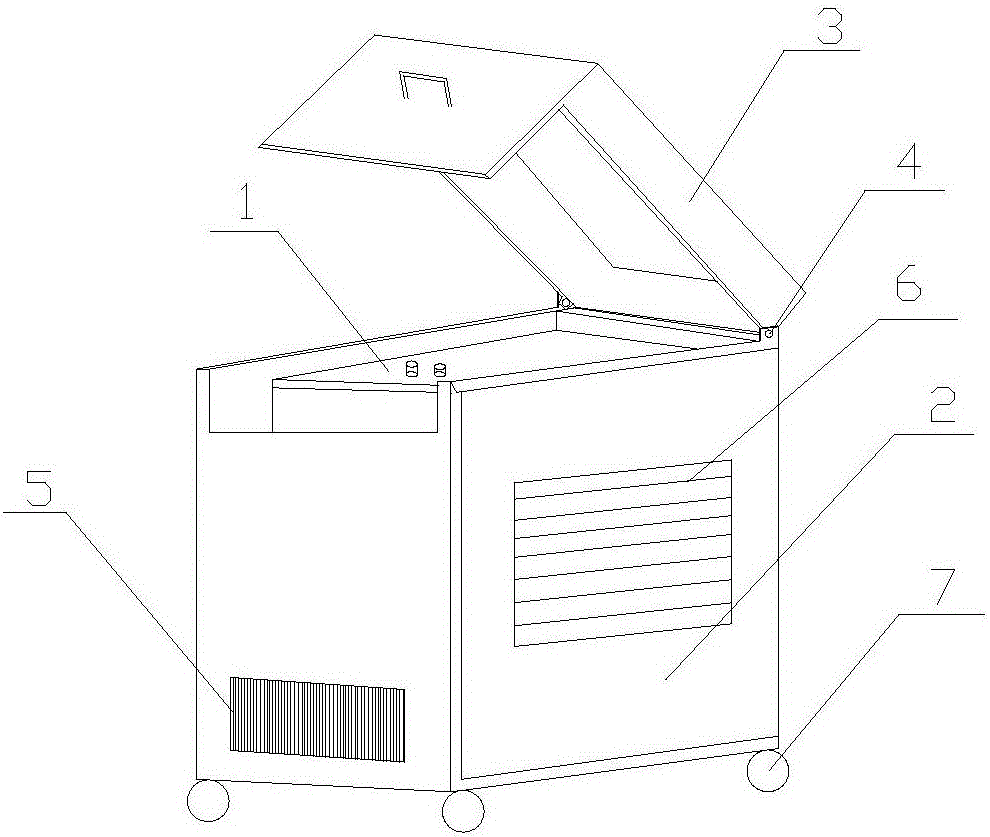

[0027] The invention provides a movable electric welding machine with good heat dissipation performance, which includes a control panel 1, a housing 2, a dustproof device 3, connecting bolts 4, heat dissipation holes 5, a heat dissipation device 6, and retractable wheels 7. The control The panel 1 is arranged on the upper end surface of the casing 2; the dustproof device 3 is installed above the casing 2; the heat dissipation device 6 is arranged on the right side of the casing 2; the telescopic wheel 7 is arranged on the casing The lower end of body 2.

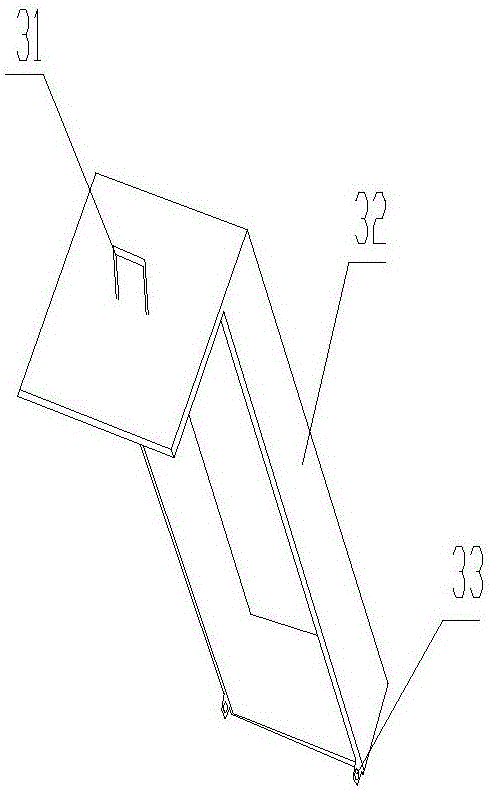

[0028] Preferably, the dustproof device 3 includes a handle 31 , a dustproof cover 32 , and a bolt hole 33 , and the handle 31 is arranged on the front of the dustproof device 3 .

[0029] Preferably, the heat dissipation device includes a safety cover 61 and a mixed flow fan 62 .

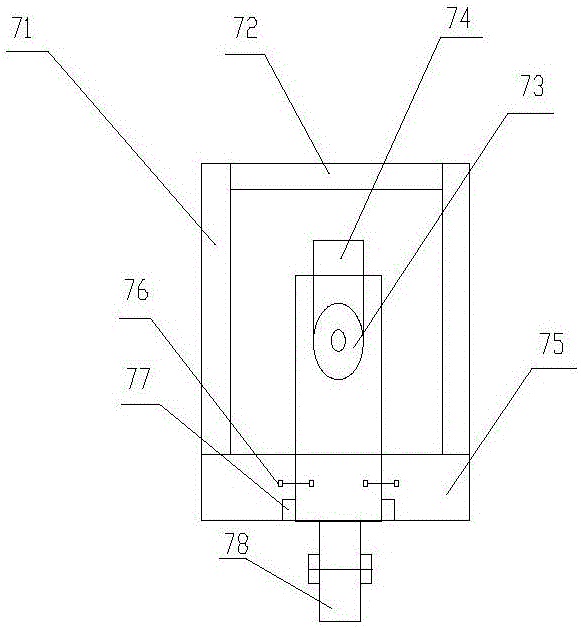

[0030] As preferably, the telescopic wheel 7 includes a vertical bar 71, a cross bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com