Method for preparing Fe-encapsulating metal carbon onions with even particle size through macroscopic quantity

A carbon onion and iron-coated technology is applied in the field of macro-scale preparation of iron-coated carbon onions with uniform particle size, which can solve the problems of high cost of internal-coated iron-coated carbon onions, great harm to the environment and laboratory personnel, and difficulty in controlling product appearance. , to achieve the effect of low equipment requirements and dependence, stable product quality, simple and controllable implementation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the present embodiment is a kind of method for macro-preparing iron metal carbon onions with uniform particle size, the method is realized according to the following steps:

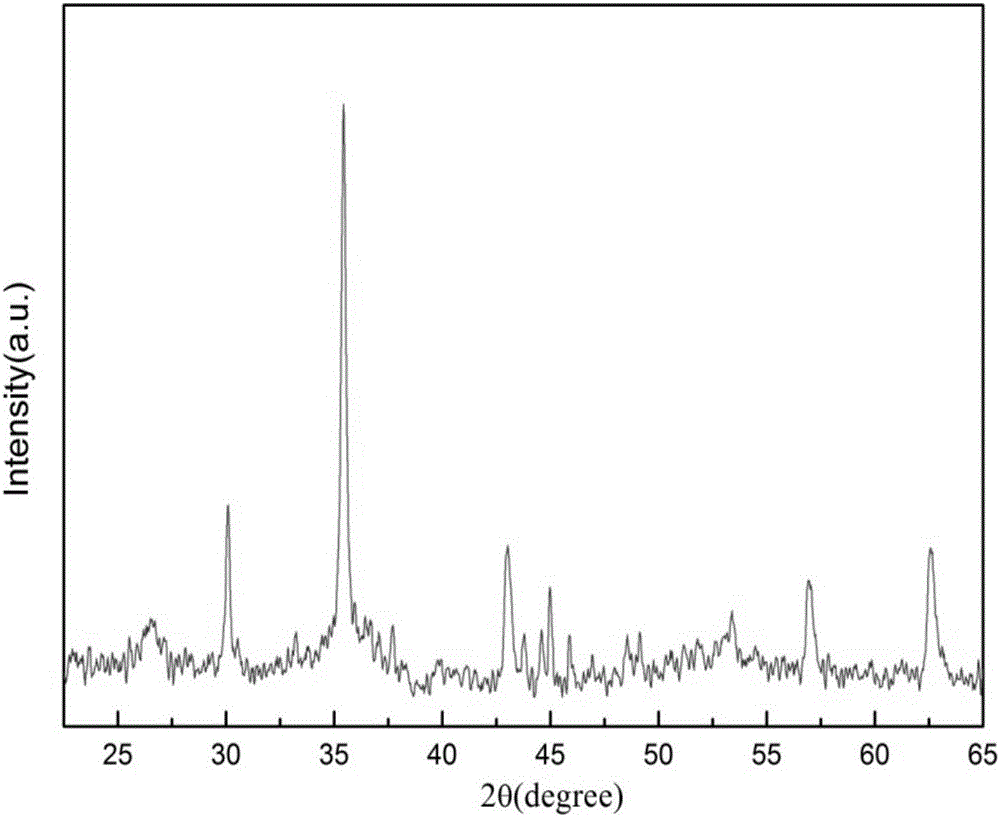

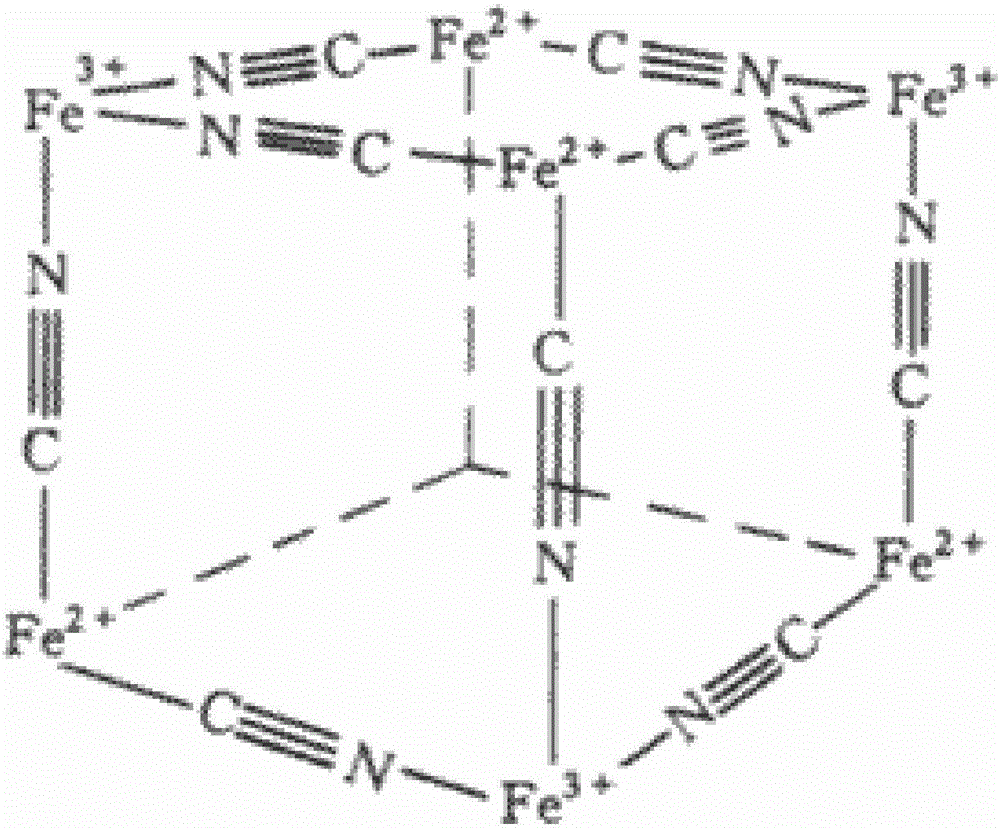

[0020] Step 1. Weigh the Prussian blue and place it in a tube furnace, heat and crack it under the condition of nitrogen protection, and cool to room temperature under the condition of nitrogen protection after the heating and cracking is completed, so as to obtain the crude product of inner-coated iron metal carbon onion; the heating and cracking process It is: heat up from room temperature to 350°C to 450°C at a heating rate of 1.5°C / min to 2.5°C / min and keep warm for 1h to 3h, then raise the temperature to 800°C to 1100°C at a heating rate of 0.5°C / min to 2°C / min Keep warm for 3h~6h;

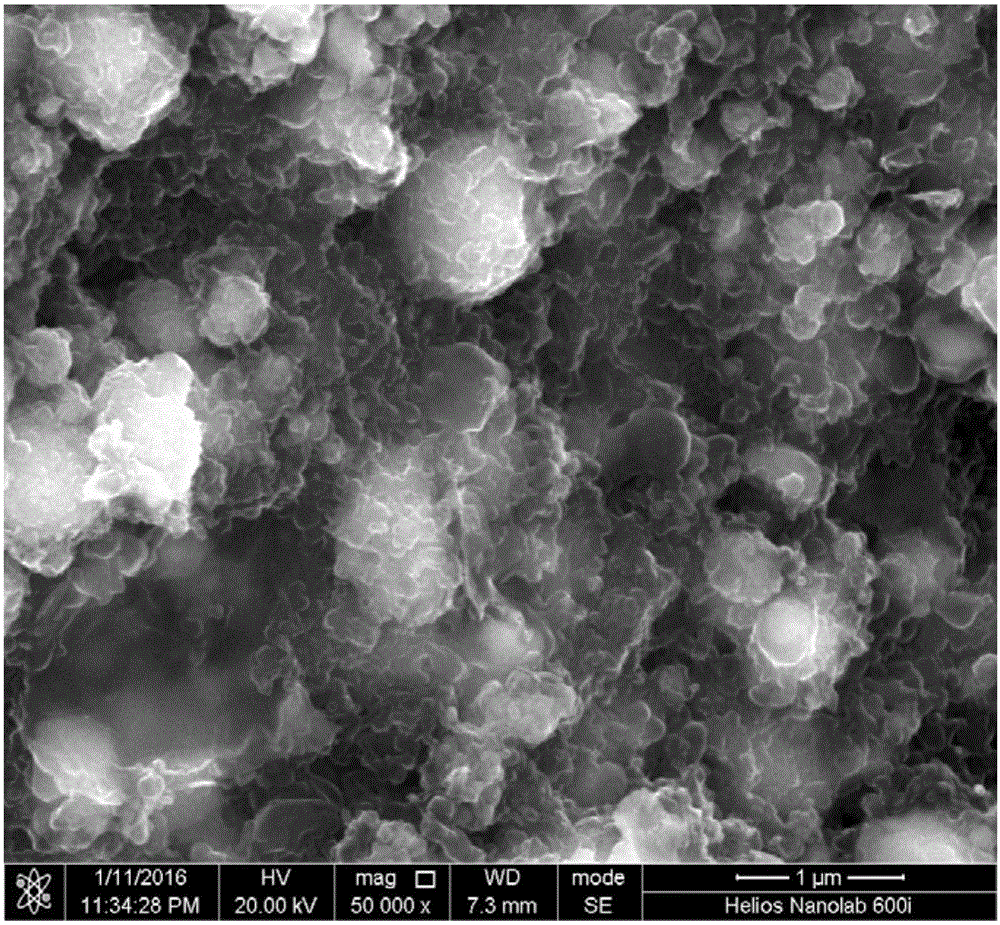

[0021] Step 2. Put the crude iron metal carbon onion prepared in step 1 into dilute hydrochloric acid, heat and reflux for 6h to 10h, then centrifuge to obtain the precipitate, wash with d...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment is different from Embodiment 1 in that: the particle size of the Prussian blue in Step 1 is 400nm-600nm. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drying process described in step 2 is to place the sediment in a blast dryer and dry it at 80° C. for 10 hours. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com