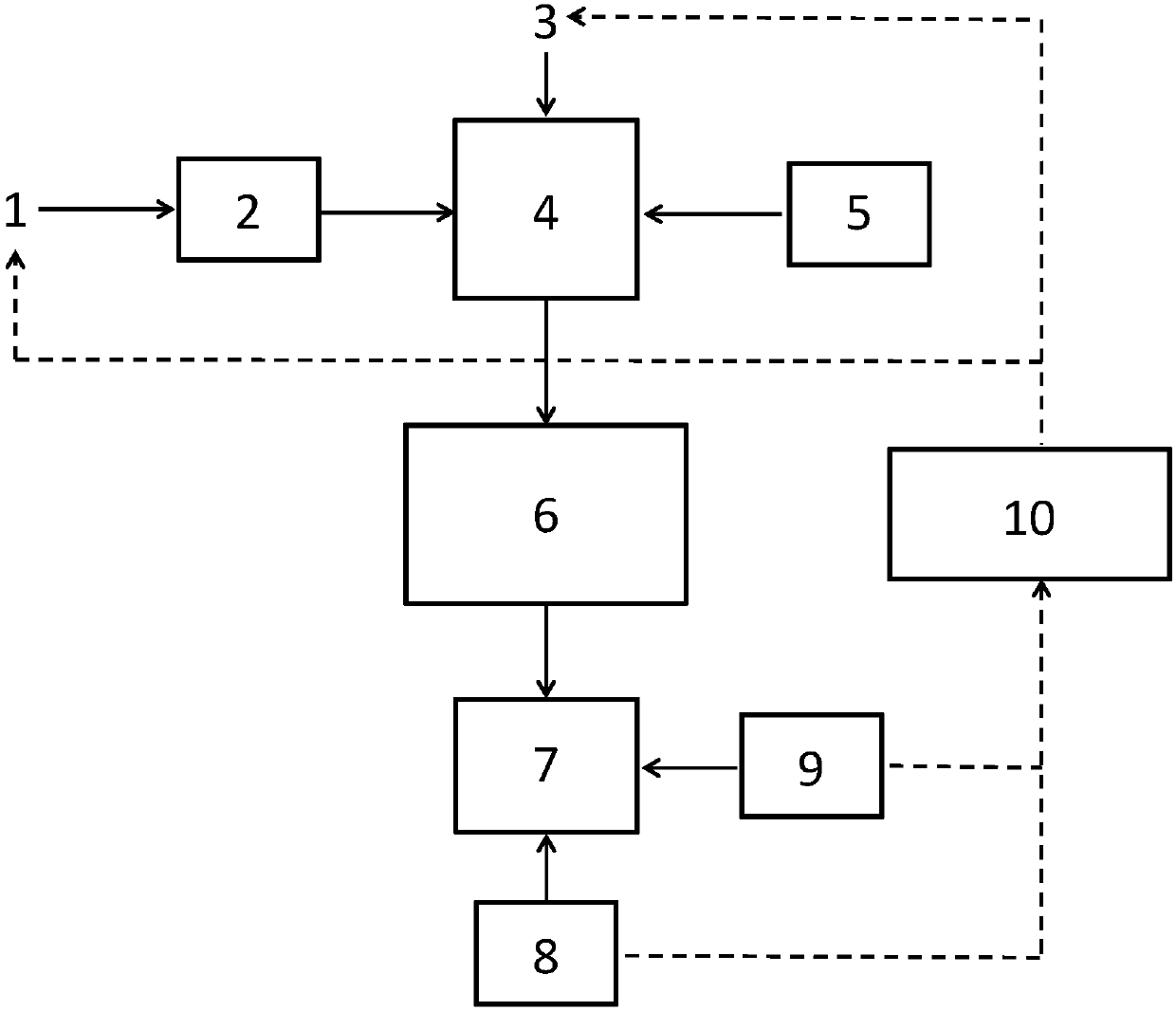

A mercury removal method and device based on online activation of activated carbon

A technology for activated carbon and mercury removal, which is applied in chemical instruments and methods, separation methods, and other chemical processes. denaturation and other problems, to achieve the effect of small impact on fly ash quality and environment, good chemical adsorption, and reduction of mercury removal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

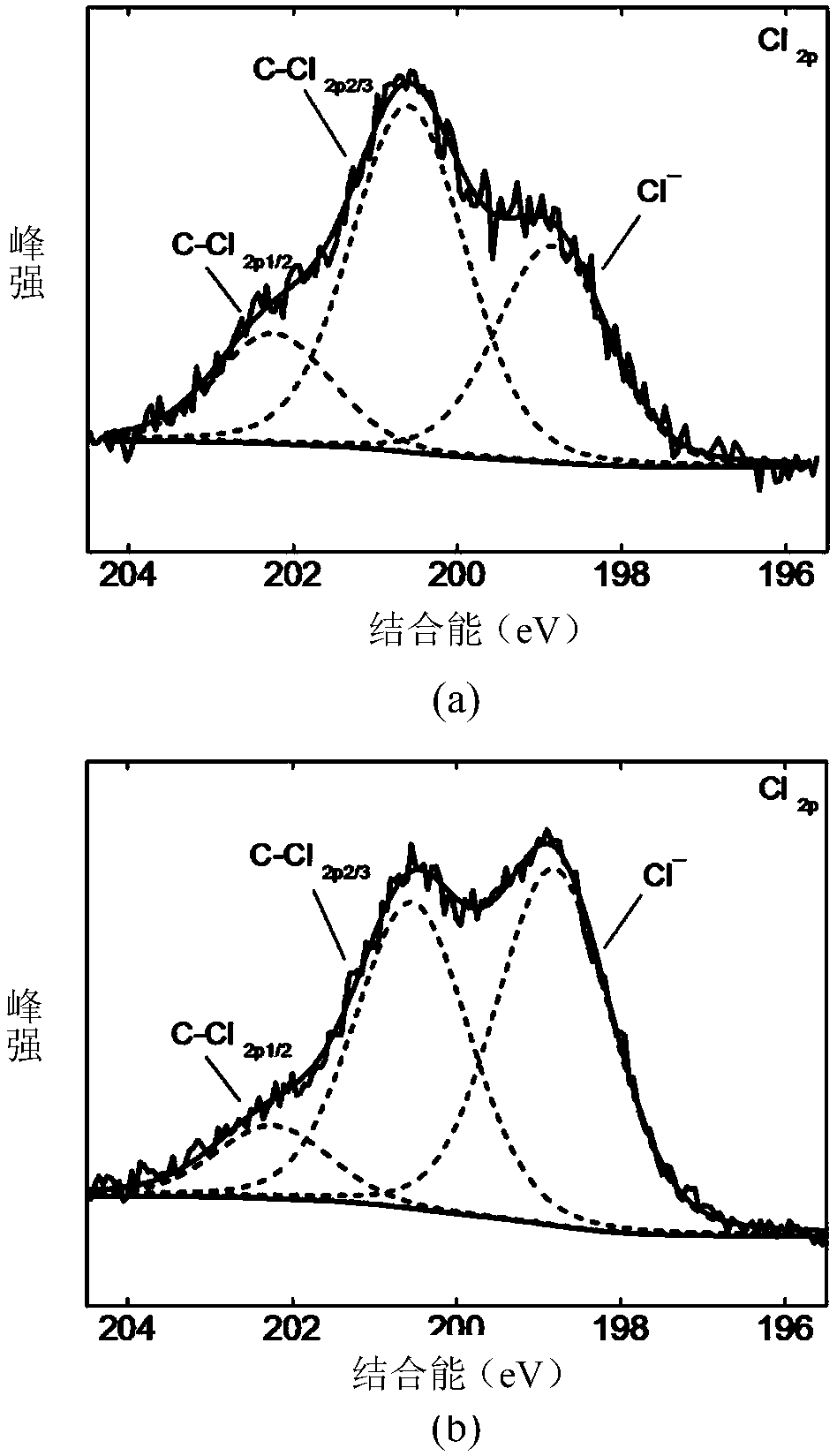

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 (this is comparative example)

[0040] Bamboo charcoal is selected as the source of activated carbon, and the powder feeding rate is 5Kg / h. When no active material and low-temperature plasma treatment device are added, the activated carbon is directly sprayed into the flue, and the removal efficiency of Hg is 36%.

Embodiment 2

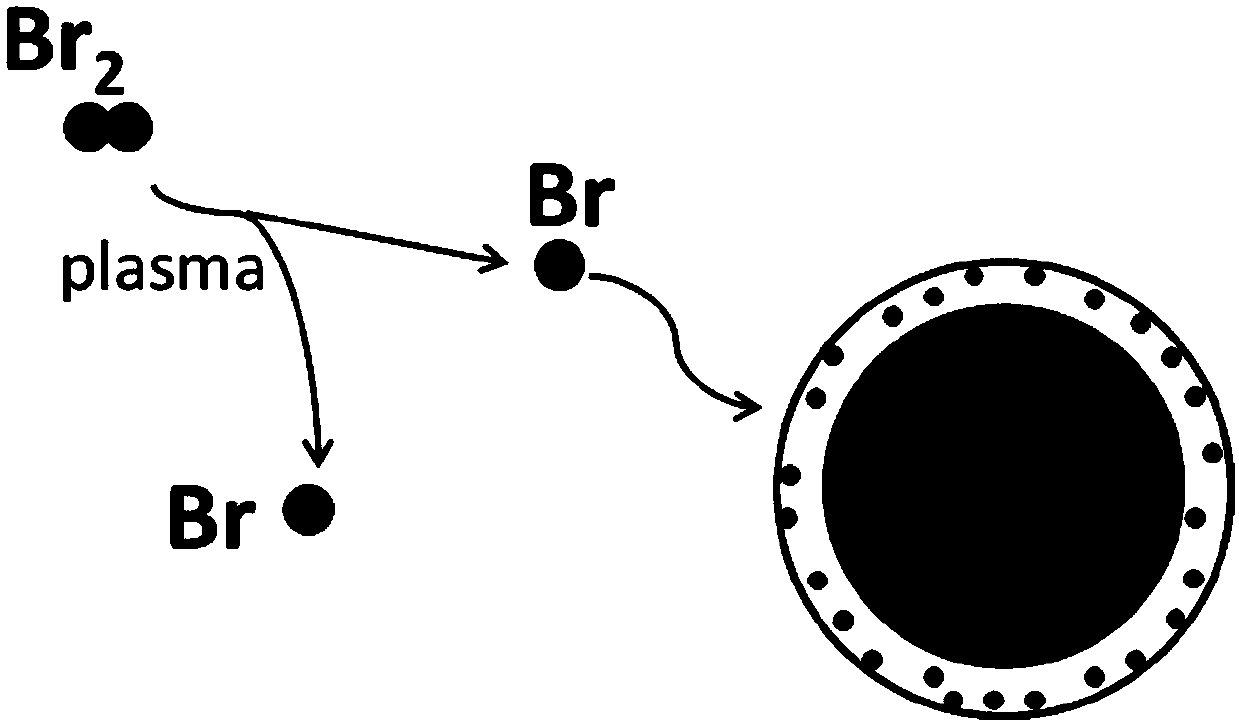

[0042] Take bamboo charcoal as the source of activated carbon, the powder feeding rate is 50Kg / h, and 0.3m 3 / h contains 10000ppm of Br 2 The air flow is sent to the plasma treatment device. The energy density of the activated carbon plasma device is 3KW, the voltage is 3KV, the frequency is 10KHz, the length of the plasma treatment device is 63cm, and the mercury removal efficiency reaches 95%.

Embodiment 3

[0044] Take coconut shell as the source of activated carbon, the powder feeding rate is 5Kg / h, and 0.3m 3 / h contains 5000ppm of Br 2 The air flow is sent to the plasma treatment device. The energy density of the activated carbon plasma device is 10KW, the voltage is 3KV, the frequency is 10KHz, the length of the plasma treatment device is 63cm, and the mercury removal efficiency reaches 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com