Potato product and method for manufacturing same

A potato and potato starch technology, applied in the field of food processing, can solve the problems of single taste, low nutritional value, and few types of potatoes, and achieve the effects of rich taste, improved nutritional value, and avoiding heat and venereal diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A potato product, wherein, in parts by weight, the potato product consists of the following components: 22 parts of whole potato powder, 18 parts of potato starch, 8 parts of white sugar, and 1.0 part of chili powder.

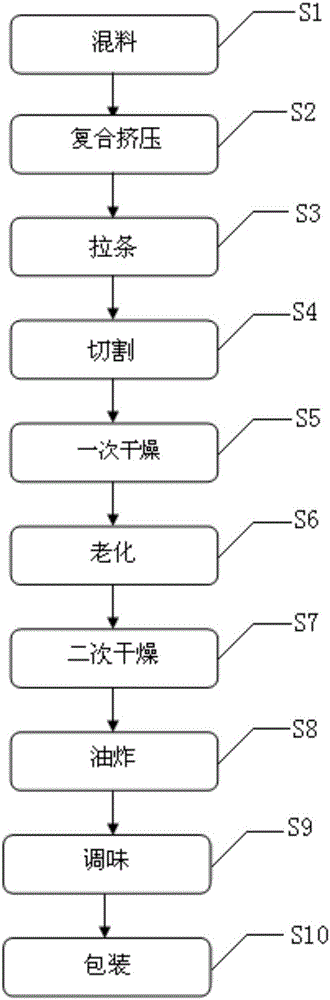

[0046] The concrete steps of the preparation method of above-mentioned potato products are as follows:

[0047](a) Mixing: After mixing the ingredients of the above formula, put them into the blender and stir them evenly, then use the automatic conveying device to transport them to the hopper;

[0048] (b) Composite extrusion: use an extrusion molding machine to perform composite extrusion molding on the materials in the hopper;

[0049] (c) Stranding: use a stretching machine to pull the compounded extruded material into strips;

[0050] (d) Cutting: Use a cutting machine to adjust the cutting size to the required scale and cut it off;

[0051] (e) primary drying; the cut material is dried quickly at low temperature by drying equipment, and the moistu...

Embodiment 2

[0058] A potato product, wherein, in parts by weight, the potato product consists of the following components: 20 parts of potato powder, 20 parts of potato starch, 10 parts of white sugar, and 1.5 parts of tomato powder.

[0059] The concrete steps of the preparation method of above-mentioned potato products are as follows:

[0060] (a) Mixing: After mixing the ingredients of the above formula, put them into the blender and stir them evenly, then use the automatic conveying device to transport them to the hopper;

[0061] (b) Composite extrusion: use an extrusion molding machine to perform composite extrusion molding on the materials in the hopper;

[0062] (c) Stretch: use a stretcher to pull the extruded material into strips;

[0063] (d) Cutting: Use a cutting machine to adjust the cutting size to the required scale and cut it off;

[0064] (e) one-time drying; the material after cutting is quickly dried by drying equipment, and the moisture content after drying is contr...

Embodiment 3

[0071] A potato product, wherein, in parts by weight, the potato product consists of the following components: 25 parts of potato snowflake whole powder, 15 parts of potato starch, 5 parts of white granulated sugar, and 0.5 part of cumin powder.

[0072] The concrete steps of the preparation method of above-mentioned potato products are as follows:

[0073] (a) Mixing: After mixing the ingredients of the above formula, put them into the blender and stir them evenly, then use the automatic conveying device to transport them to the hopper;

[0074] (b) Composite extrusion: use an extrusion molding machine to perform composite extrusion molding on the materials in the hopper;

[0075] (c) Stretch: use a stretcher to pull the extruded material into strips;

[0076] (d) Cutting: Use a cutting machine to adjust the cutting size to the required scale and cut it off;

[0077] (e) one-time drying; the material after cutting is quickly dried by drying equipment, and the moisture conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com