Smoked fish drying device driven to rotate by sine wave thermal expansion

A drying device and sine wave technology, applied in the direction of drying and preserving meat/fish, meat/fish preservation, food preservation, etc. The effect of reducing energy loss, reducing drying energy consumption, and promoting drying and dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with accompanying drawing, the present invention is described in further detail.

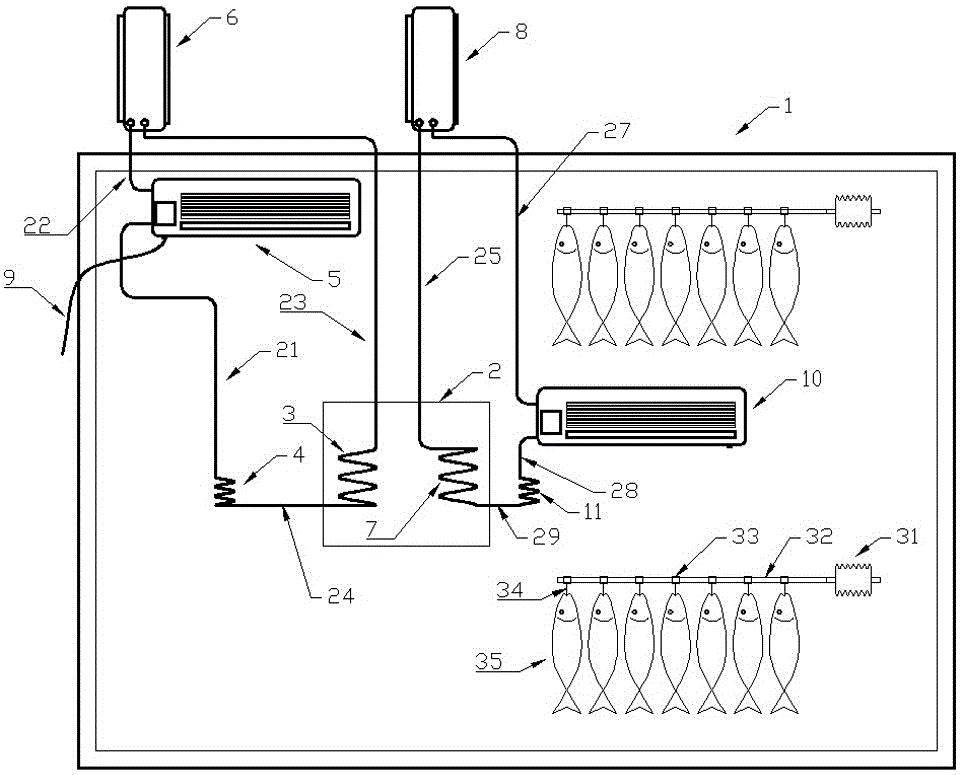

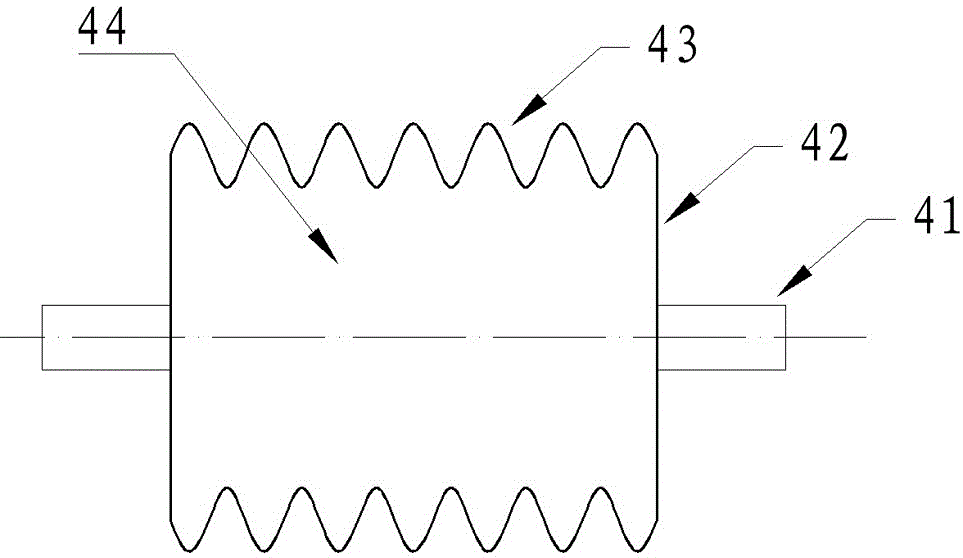

[0023] Such as figure 1 with figure 2 The shown sine wave thermal expansion drives and rotates the cured fish drying device. The device is isolated from the external environment by the thermal insulation enclosure 1. The thermal insulation enclosure 1 constitutes a dry working environment, wherein there is a water tank 2, and the water tank 2 is provided with spiral coils A3, Spiral coil tube B7 and inject appropriate amount of water to submerge the spiral coil tube; compressor A6, spiral coil tube A3, capillary tube A4, refrigerating and air-conditioning internal unit 5 and pipelines 21, 22, 23, 24 constitute a group A heat pump circulation dehumidification system, in which the compressor A6 is connected to the spiral coil tube A3 through the pipeline 23, and the spiral coil tube A3 is connected to the capillary tube A4 through the pipeline 24, and the capillary tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com