Flue-cured tobacco intertill hiller

A soil cultivator and flue-cured tobacco technology, which is applied in the fields of application, land preparation machinery, agricultural machinery and machinery and tools, can solve the problems of time-consuming, labor-intensive, labor-intensive, and insufficient labor in smoking areas, so as to ensure the depth of the ditch bottom and strong adaptability , Efficient ditching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings.

[0026] See Figure 1-Figure 4 .

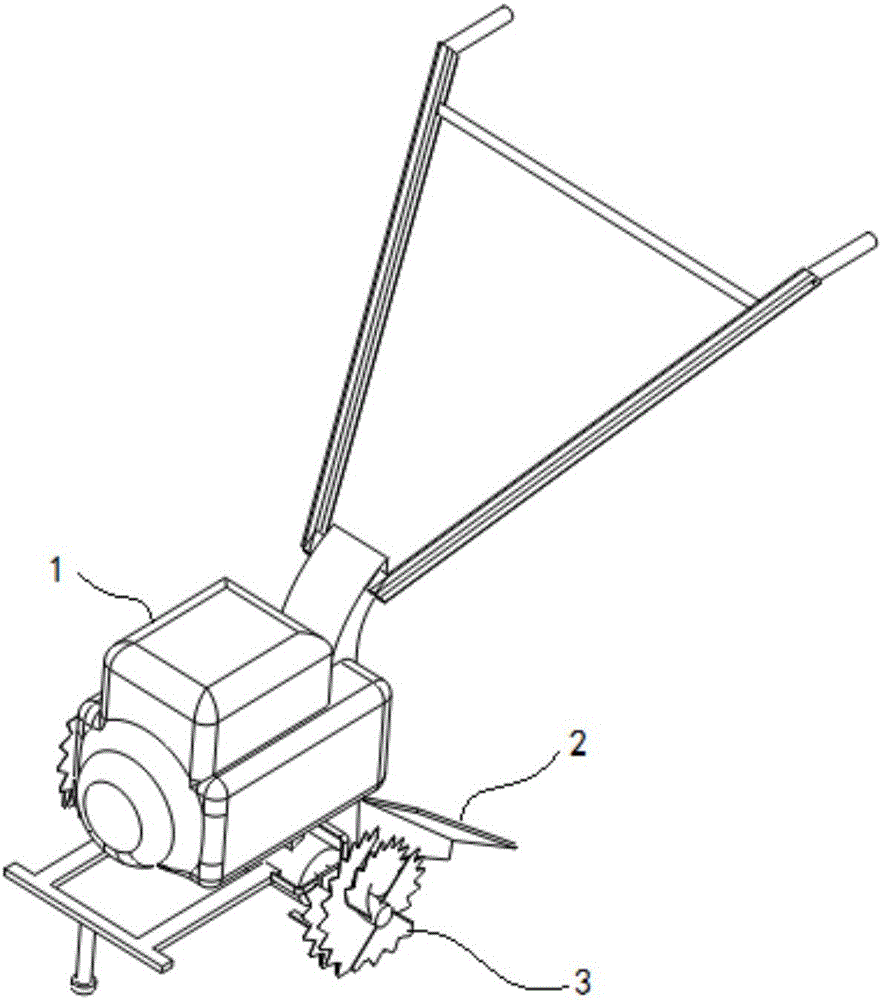

[0027] A flue-cured tobacco cultivator, comprising a pair of soil cultivation wheels 3, a shaper 2 and a traction power mechanism 1:

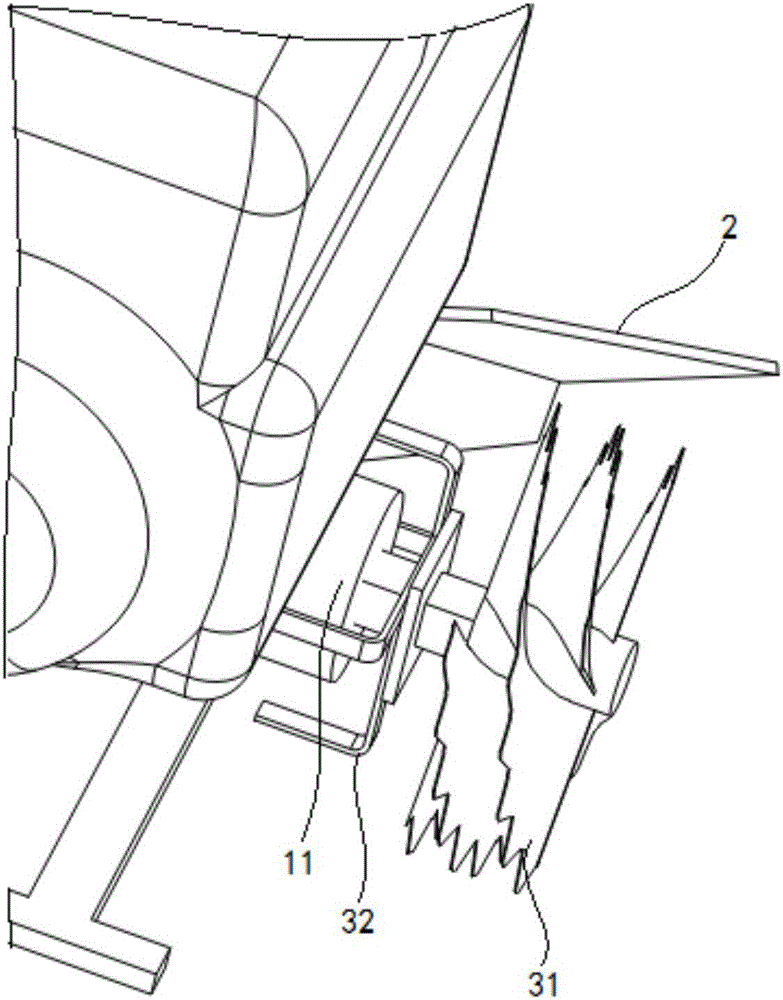

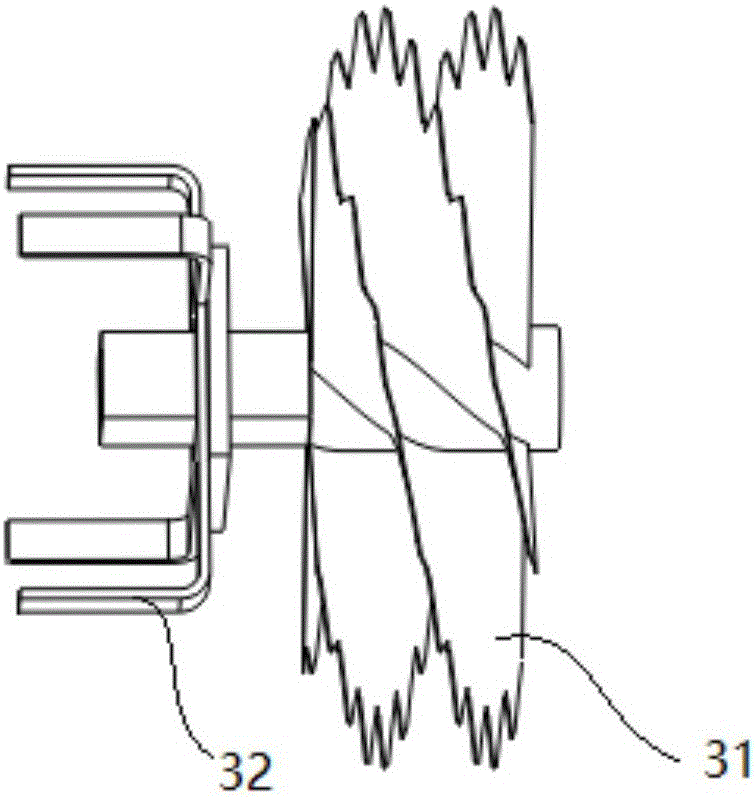

[0028] The pair of soil-building wheels 3 are installed on the left and right sides of the traction power mechanism 1 through the transmission shaft 11. The soil-building wheels 3 include a gear blade 31 spirally installed at the end of the transmission shaft 11 and a rotary tiller installed at the end of the gear blade 31. Knife 32, such as figure 2 , image 3 ;

[0029] Such as Figure 4 , the shaper 2 is installed on the lower part of the rear side of the traction power mechanism 1 through the traction hook 21. The shaper 2 is also provided with a guide body 23 and a scraper 22. The guide body 23 forms an acute angle guide structure, and the scraper 22 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com