Integrally moulded PET base material protective back film containing impression

A back film, integrated technology, applied in the field of PET substrate protection back film, can solve the problems of bending or breaking the protective film and the back film, difficult peeling of the back film and the protective film, affecting the performance of the protective film, etc. The effect of easy bending, improving yield rate, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

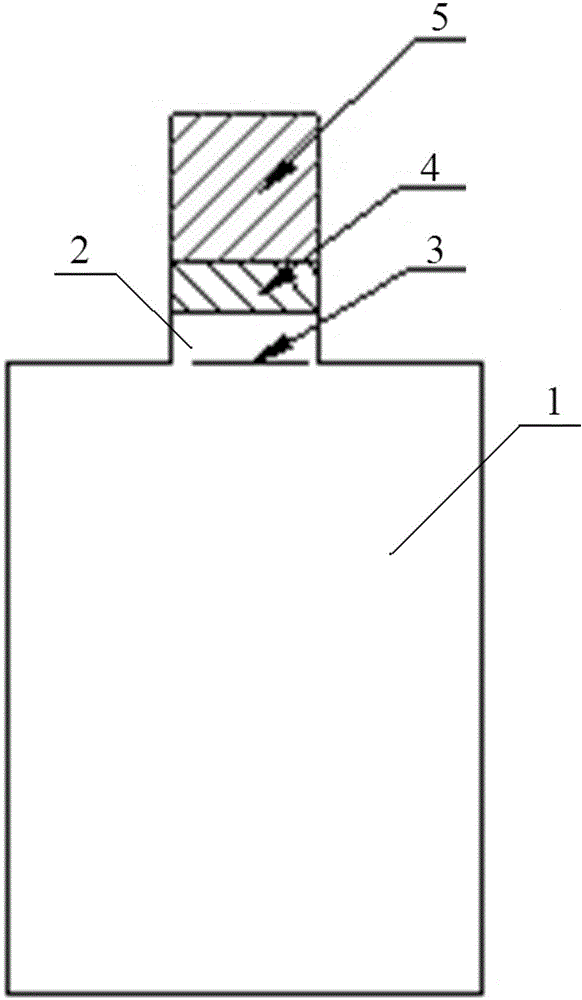

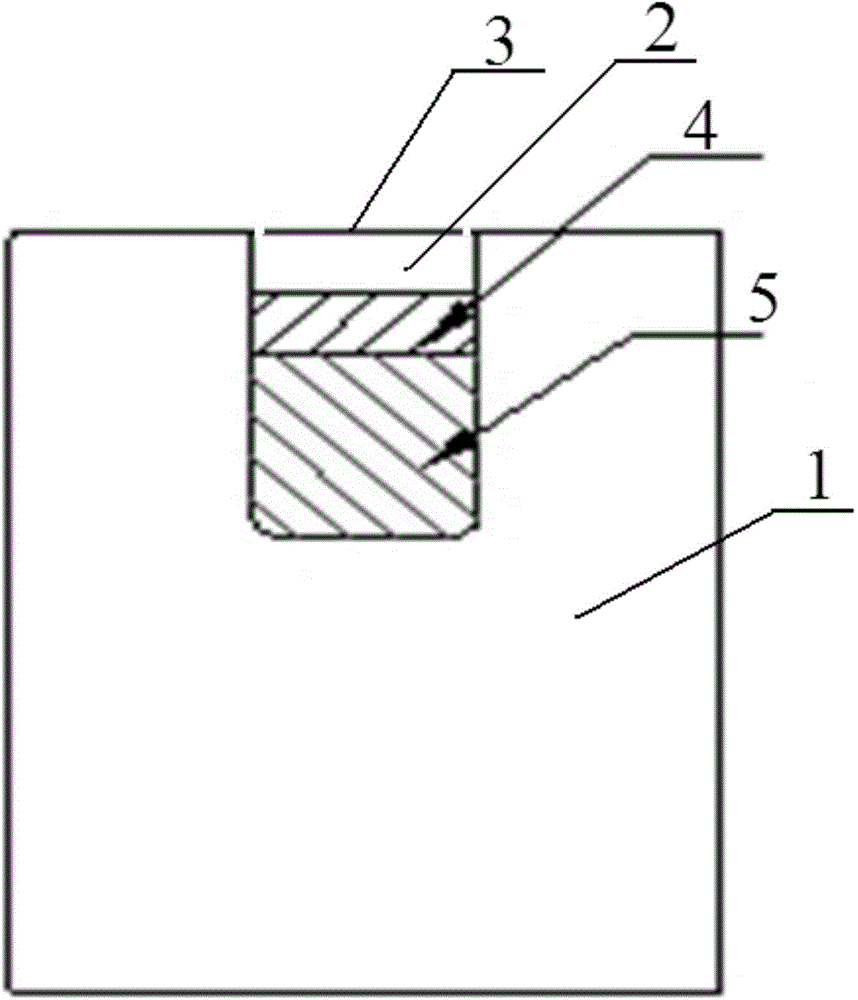

[0022] One-piece protective back film on PET substrate with indentations, such as figure 1 As shown, the back film body 1 is included, the two sides of the back film body 1 are smooth horizontal planes, the front side of the back film body 1 is used to bond a protective film with the same shape as the back film body 1, and the top of the back film body 1 is provided with a The hand 2, the handle 2 and the back film body 1 are integrally formed, and the boundary between the handle 2 and the back film body 1 is provided with an indentation line 3, and the length of the indentation line 3 is the same as that of the handle 2. The depth of the creasing line 3 is 1 / 3-2 / 3 of the thickness of the back film body 1 . The depth of the creasing line 3 is set to ensure that the creasing line 3 does not cut through the back film body 1 . The creasing line 3 is located at the back boundary of the back film body 1 . The handle 2 is provided with a double-sided adhesive 4, which is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com