Method for processing mellow-thick green tea

A processing method and technology for green tea, applied in the direction of tea treatment before extraction, etc., can solve the problems of insufficient concentration and weak taste, and achieve the effects of facilitating dissolution, increasing dissolution, and ensuring color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

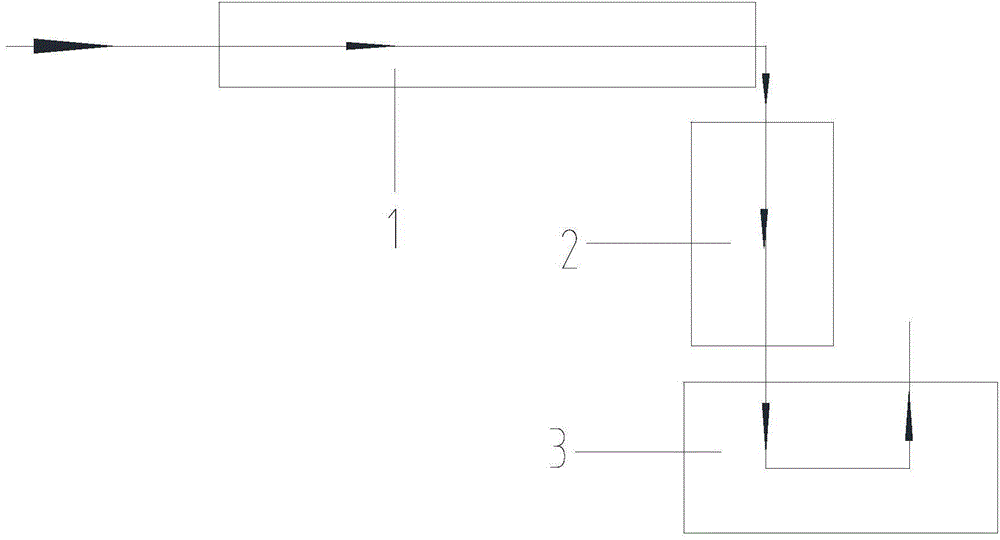

[0023] For the processing of Longjing, the raw materials of one bud and one leaf are put into the roller degreening machine 1 for degreening, and the decapitation time is about 3 minutes. , It is recommended to use microwave energy above 100KW 2450MHZ. The high power density microwave heating equipment is preferably customized into a vertical cylinder shape. , rapid cooling until normal temperature, freezing using a general-purpose freezer, preferably custom-made minus 10 degrees, and preparing a freezer with a micro-fan in the freezing space; the cooled tea leaves are fried by hand using known techniques, and finally refired until they are dry enough.

[0024] According to the evaluation of the produced products, the color of the dry tea is yellow-green, the color of the leaves is light green, the burnt aroma is obvious, and the tea soup is rich and delicious, which is obviously stronger than the tea processed by traditional techniques.

Embodiment 2

[0026] For the processing of Biluochun, the raw materials of one bud and one leaf are put into the roller degreening machine 1 for degreening, and the decapitation time is about 3 minutes. , It is recommended to use microwave energy above 100KW 2450MHZ. The high power density microwave heating equipment is preferably customized into a vertical cylinder shape. , quickly cool down to normal temperature, and use a general-purpose freezer for freezing, preferably a custom-made freezer at minus 20 degrees, and prepare a freezer with a micro fan in the freezing space; the cooled tea leaves are kneaded on a kneading machine, and then placed in an electric frying pan when the time is reached for rubbing Manually rub the snails to lift the hair, and finally dry it in the dryer until it is fully dry.

[0027] The tea leaves made by traditional crafts were used as a comparison, and the evaluation and comparison of tea were carried out. It was found that there was no difference in the col...

Embodiment 3

[0029] For the processing of high-grade tea, put the single bud or one bud and one leaf raw material into the roller degreening machine 1 for degreening, the decapitation time is about 3 minutes, and the degree of decapitation is controlled according to the heat degree slightly higher than the known; the decapitated leaves are then put into the high power density microwave equipment 2. For cell cracking, it is recommended to use microwave energy above 100KW and 2450MHZ. The high-power-density microwave heating equipment is preferably customized as a vertical cylinder. Fall into the freezing space 3, quickly cool down to normal temperature, and use a general-purpose freezer for freezing, preferably a custom-made freezer at minus 20 degrees, and prepare a freezer with a micro fan in the freezing space; the cooled tea leaves are sorted on the slitting machine to reach the plodding time After pressing the stick for about 10 minutes, take it out of the pan, let it cool for half an h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com