Current sharing circuit based on LED voltage-boosting constant current drive

A constant current drive and circuit technology, applied in the field of dual-channel parallel drive control circuits, can solve the problems that the voltage characteristics of two LED strings cannot be guaranteed, the existence of LED string current errors, and software parameters need to be redesigned, etc., to achieve a wide range of use, Timely response, simple production and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

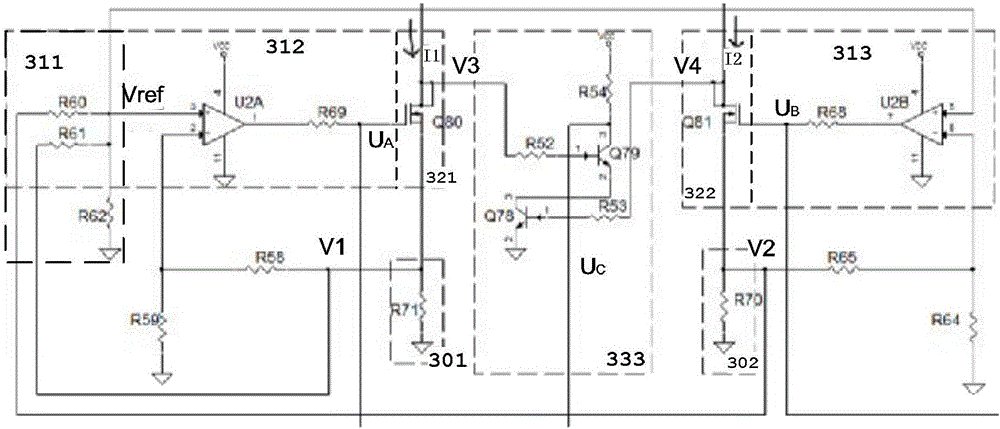

[0041] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

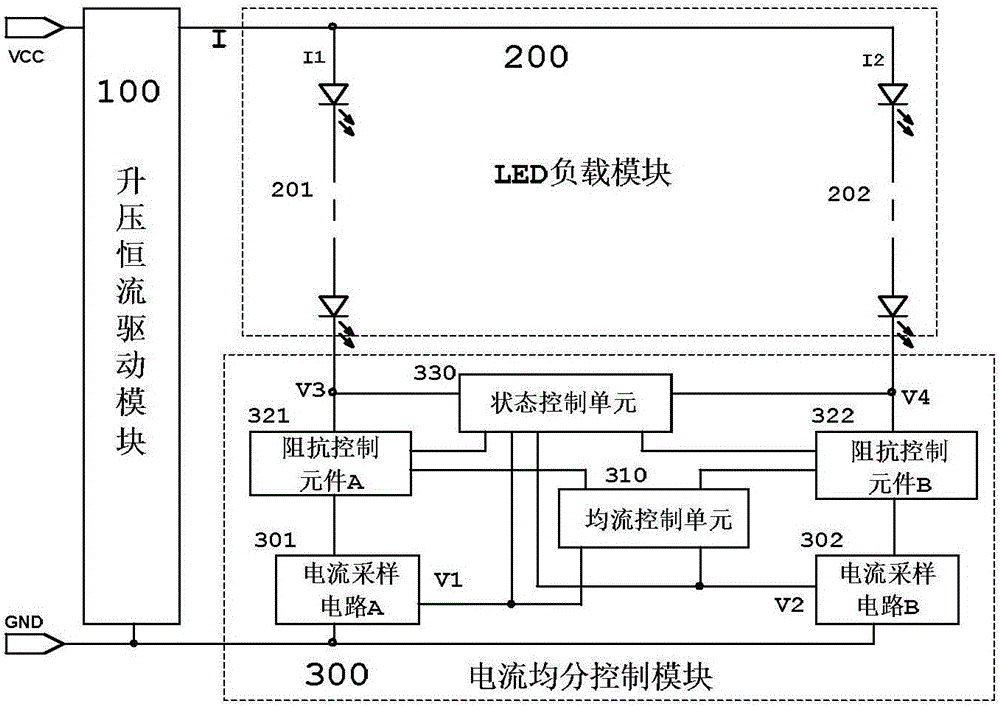

[0042] The principle block diagram of the current sharing circuit based on LED boost constant current drive of the present invention is as follows: figure 1 As shown, it consists of a boost constant current drive module 100, an LED load module 200 and a current sharing control module 300. The boost constant current drive module 100 is connected to the vehicle low-voltage DC power supply to provide constant current for the LED load module 200. drive current;

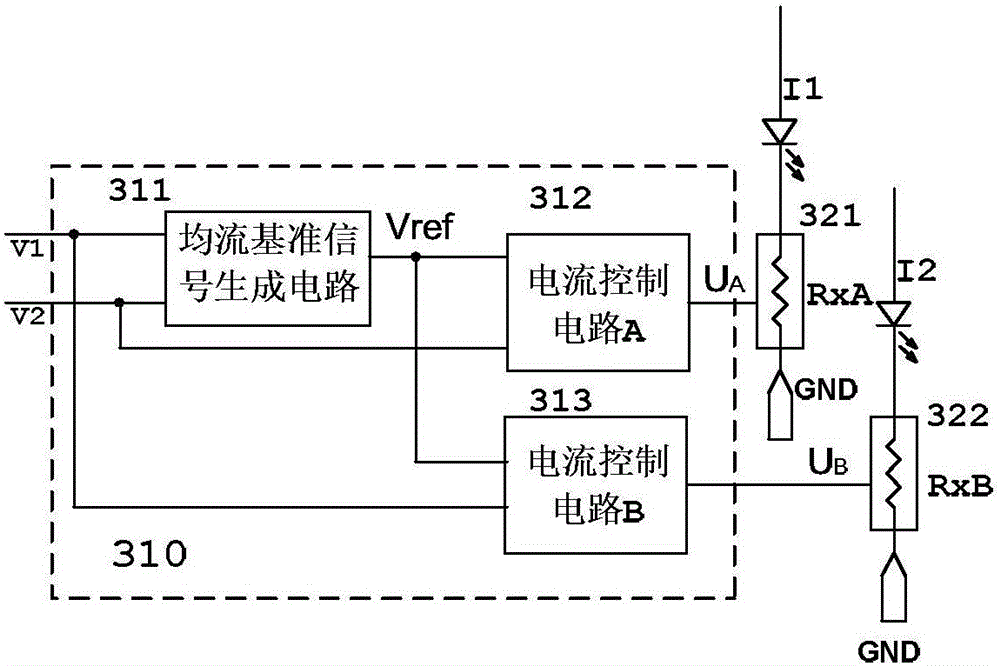

[0043] The LED load module 200 is composed of an LED string A 201 and an LED string B 202, the positive ends of the LED string A 201 and the LED string B 202 are connected in parallel to the constant current drive current output end of the boost constant current drive module 100, and the LED The negative ends of the string A 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com