Train main and auxiliary integrated traction converter capable of being axially controlled independently

A technology of traction converters and converters, which is applied in the direction of converting AC power input into AC power output, output power conversion devices, electrical components, etc. The problem of heavy weight of the converter is achieved, which is conducive to structural layout and lightweight design, adding auxiliary grounding protection and charging functions in the warehouse, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification.

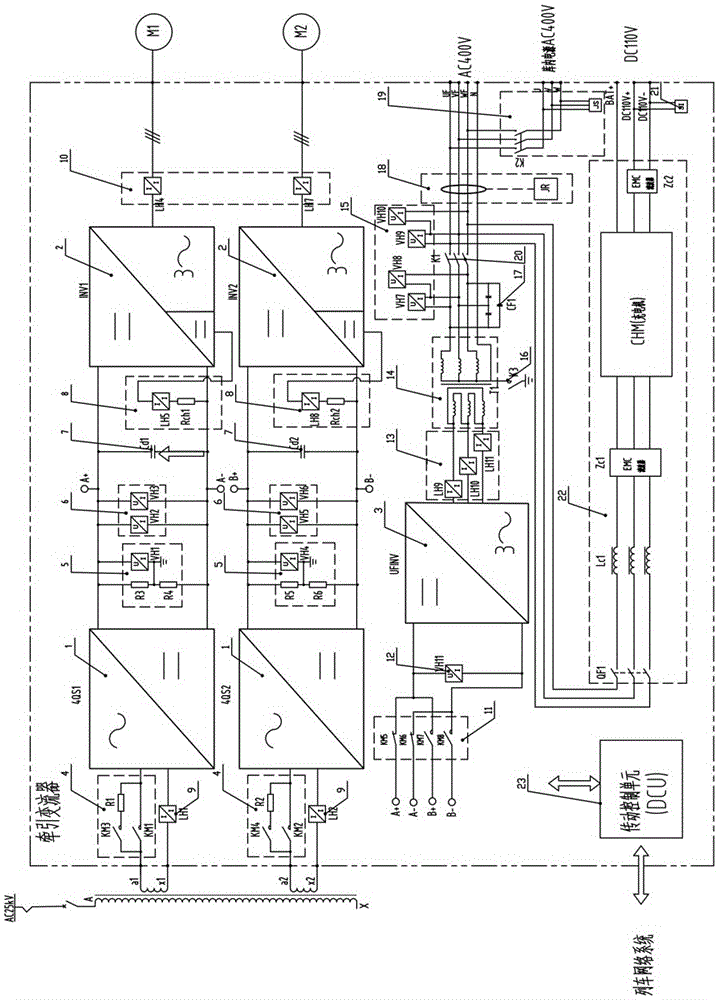

[0027] Such as figure 1 As shown, the train main and auxiliary integrated traction converter with independent axis control of the present invention includes two completely independent converter units and an auxiliary inverter 3. The auxiliary inverter 3 is used for switching through the auxiliary inverter. The cutting device 11 is freely switched on and off in the intermediate DC link 7 of the double converter, and its back end is connected with an auxiliary transformer 14 to provide electrical energy for the charger and auxiliary load after voltage reduction; each converter unit includes:

[0028] Four-quadrant rectifier 1, used for AC-DC conversion of single-phase AC power in the pantograph network;

[0029] The main inverter 2 is used to change the intermediate direct current into three-phase alternating current for the traction mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com