Automatic conduit moving and overturning mechanism

An automatic moving and flipping mechanism technology, which is applied in the direction of cable installation devices, electrical components, equipment for dismantling/armouring cables, etc., can solve the problems of sagging tail wires, easily damaged wire cores, easily damaged wires, etc., and achieve reasonable design, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

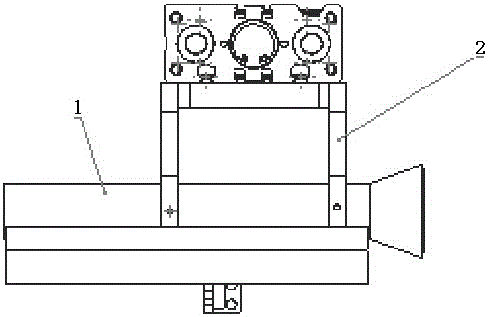

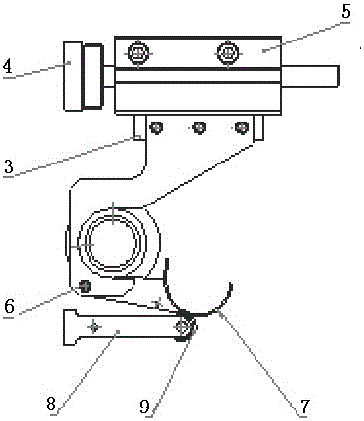

[0015] Depend on Figure 1-4 It can be seen that a conduit automatic moving and turning mechanism includes a cylinder 5, a cylinder mounting plate 4, a conduit 1, a conduit seat 2, a mounting plate 3, a rotating rod 6, a material guide groove 7, a bearing 9 and a bearing mounting seat 8. The conduit 1 is fixed on the conduit base 2, the conduit base 2 is installed on the mounting plate 3, the cylinder 5 is fixed on the mounting plate 3 and the cylinder mounting plate 4, the guide groove 7 passes through the rotating rod 6 and is connected to the conduit base 2, and the guide Feed chute 7 can rotate freely, and bearing 9 is installed on the bearing mount 8, and bearing 9 supports feed chute 7.

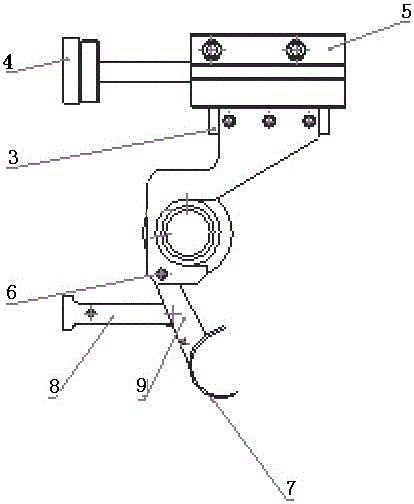

[0016] Wherein the cylinder mounting plate 4 is fixed on the panel, when the cylinder 5 stretches out, as image 3 At this time, the center of the catheter is aligned with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com