Anti-drop insulation piercing connector

An insulation piercing and wire clip technology, which is applied in the direction of fastening/insulation connectors, needle points/slotted plate contacts used for penetrating insulated wires/cable core wires, electrical components, etc., which can solve major losses and safety problems and other problems to achieve the effect of prolonging the service life and avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

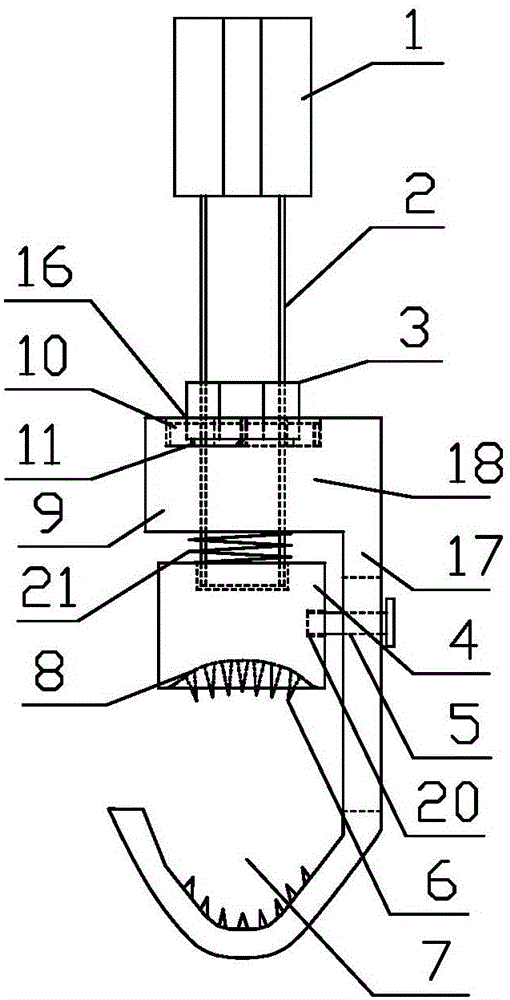

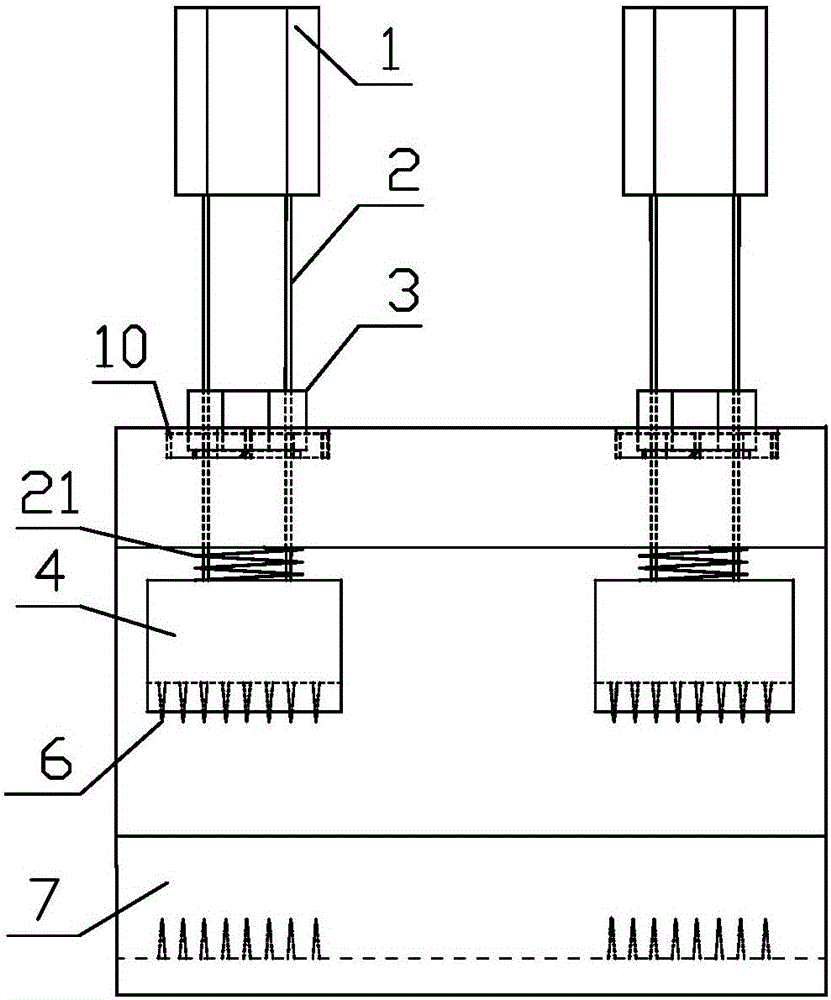

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 , 2 The anti-off insulation piercing clamp shown in , is provided with a J-shaped clamp 9, a pair of screw rods 2, a chuck 4 and a pair of locking parts 16.

[0024] The J-shaped clip 9 is horizontally columnar, and is provided with a vertically corresponding upper platform 18 and a lower wire slot 7. Only one side is provided with a connecting vertical plate 17 between the upper platform 18 and the lower wire slot 7, and the other side is open. The upper platform runs through a pair of screw holes; a pair of the screw rods 2 are threadedly connected with the pair of screw holes respectively, the outer end of the screw rod is provided with a hexagonal head 1 , and the inner end of the screw rod is sleeved with the chuck 4 . Collet 4 can be a pair, is respectively located at the bottom of a pair of screw rods 2, also can be a collet connected as a whole,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com