Experimental device for simulating operation of medium in cryogenic pump

An experimental device and cryogenic pump technology, applied in pump control, non-variable pumps, machines/engines, etc., can solve problems such as the inability to directly observe the operation process of the medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: An experimental device for simulating the operation of a medium in a cryopump

[0036] Embodiment 1 provides an experimental device for simulating the operation of a medium in a cryopump, and its structure will be described in detail below.

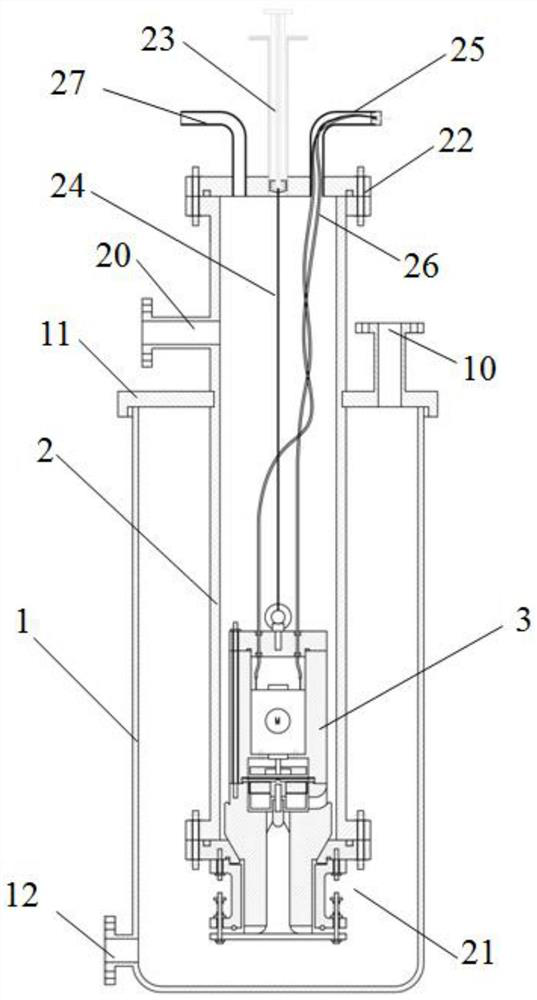

[0037] refer to figure 1 with Figure 4 , the experimental device for simulating the operation of the medium in the cryopump includes a storage tank 1, a pump well pipe 2 and a pump body 3,

[0038] The storage tank 1 is equipped with a cover plate 11, the pump well pipe 2 extends into the storage tank 1 through the cover plate 11, and the pump well pipe 2 is sealed and fixedly connected with the cover plate 11;

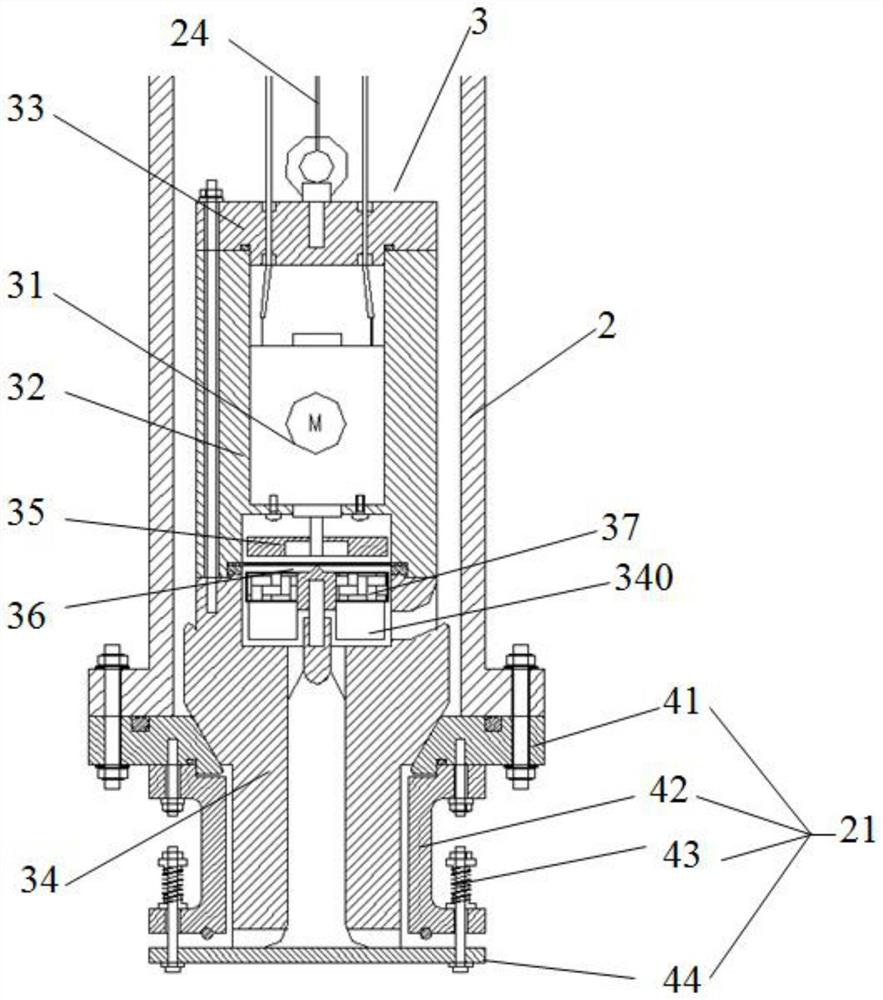

[0039] The bottom end and the top end of the pump well pipe 2 are respectively equipped with a bottom valve 21 and a top plate 22, and the pump body 3 can be suspended in the pump well pipe 2;

[0040] The cover plate 11 is provided with a liquid inlet 10, and the pump well pipe 2 above the cover plate 11 is...

Embodiment 2

[0063] Example 2: An experimental method for observing the operating state of different flow rates of liquid media flowing through the pump body

[0064] Embodiment 2 provides an experimental method for observing the operating state of liquid media with different flow rates flowing through the pump body. The experimental device provided in Embodiment 1 for simulating the operation of a medium in a cryopump is used. The experimental method includes the following steps:

[0065] Close the liquid discharge port 12, inject liquid medium into the liquid inlet 10, the liquid medium gathers at the bottom of the storage tank 1, overflows the bottom valve 21, until the liquid medium flows into the pump body 3 through the bottom valve 21;

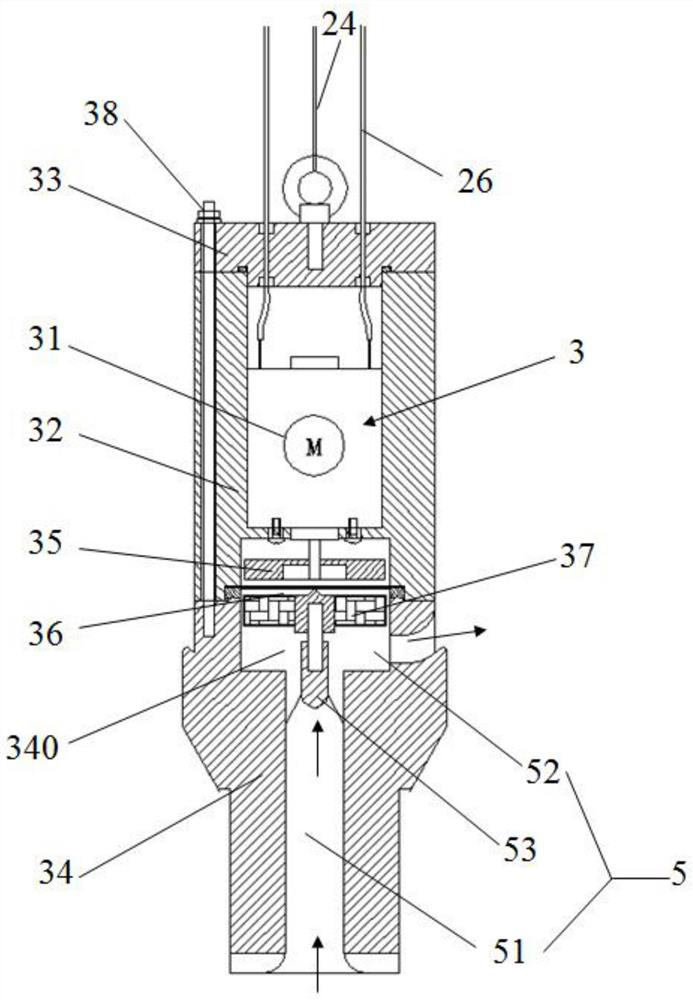

[0066] Start the pump body 3, the wire 26 introduces the current into the DC motor 31, and the rotation of the DC motor 31 drives the rotation of the permanent magnet 35;

[0067] The permanent magnet 35 interacts with the heteropolar permanent magne...

Embodiment 3

[0072] Example 3: An experimental method for simulating pump body disassembly and medium replacement

[0073] Embodiment 3 provides an experimental method for simulating pump disassembly and medium replacement. The experimental device for simulating the operation of a medium in a cryopump provided in Embodiment 1 is used. The experimental method includes the following steps:

[0074] Turn off the power supply, and the pump body 3 stops running;

[0075] Pull the needle piston 23 upwards, connect the sling 24 to lift the pump body 3, the spring assembly 43 pulls the valve plate 44 upwards, the valve plate 44 contacts the seal on the lower valve body 20, and the bottom valve 21 realizes sealing;

[0076] Lock the position of the needle piston 23, suspend the pump body 3 in the pump well pipe 2, and close the valve on the liquid outlet 20;

[0077] Use an air compressor to inject air into the gas injection port 27, the air is injected into the pump well pipe 2, and the air press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com