Lens and method for generating vortex beam based on reflecting super-surface

A metasurface, reflective technology, used in electrical components, antennas, etc., can solve problems such as thickness limitations, and achieve the effect of operating frequency bandwidth, efficient generation, and overcoming thickness limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

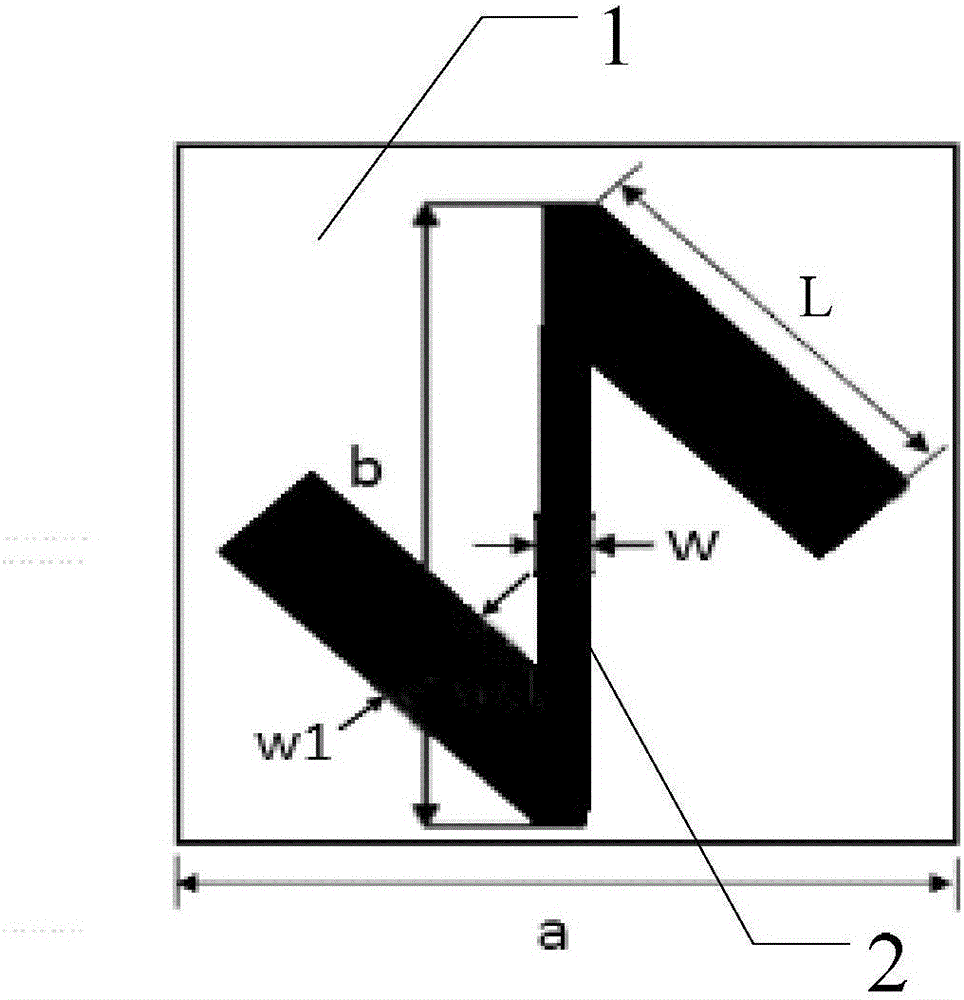

[0021] Specific implementation mode one: combine figure 1 Specifically explain this embodiment, the lens for generating a vortex beam based on a reflective metasurface described in this embodiment includes m×n periodically arranged phase mutation units, and both m and n are positive integers;

[0022] Each phase mutation unit includes a substrate 1 and an inverse Z-shaped metal layer 2 located on the surface of the substrate,

[0023] Inverse Z-shaped metal layer 2 includes metal strip one 2-1, metal strip two 2-2 and inclined strip 2-3, metal strip one 2-1 and metal strip two 2-2 are parallel, and inclined strip 2-3 connects the metal strip One 2-1 and metal strip two 2-2, take one side of the substrate as the x-axis, the side adjacent to this side as the y-axis, and the angle between the center line of the inclined strip 2-3 and the y-axis is θ, where l is the number of orbital angular momentum, The value range of is [0,2π), and x and y are respectively the abscissa an...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 2 and image 3 Describe this embodiment in detail. This embodiment is a further description of the lens that generates a vortex beam based on a reflective metasurface described in Embodiment 1. In this embodiment, the substrate 1 is a square, and the side length a is 16.2mm. The length L of the first metal strip 2-1 and the second metal strip 2-2 is 9.24mm, and the width w1 is 2.7mm. The length b of the inclined strip 2-3 is 14.88mm, and the width w is 0.54mm. The phase mutation unit The thickness is 3mm.

[0030] The thickness of the phase mutation unit is 3mm, which is one-tenth of the wavelength corresponding to the center frequency of 10GHz in the 8GHz-12GHz working bandwidth, which is a sub-wavelength thickness. The phase mutation unit has a band-pass transmission characteristic for circularly polarized electromagnetic waves.

[0031] image 3 It is the cross-polarized wave reflection coefficient graph, it ca...

specific Embodiment approach 3

[0032] Specific implementation mode three: combination Figure 4 and Figure 5 Describe this embodiment in detail. This embodiment is a further description of the lens that generates vortex beams based on the reflective metasurface described in Embodiment 2. In this embodiment, m×n is a rectangular array, along the positive direction of the x-axis In the same period of , the relative rotation angle of adjacent phase mutation units is π / 6, and the counterclockwise direction is positive, and the clockwise direction is negative.

[0033] For a lens with a horizontal phase gradient, such as Figure 4 As shown, there are two components with different handedness in the reflected field, and the propagating direction of the component that maintains the handedness of the incident circularly polarized wave conforms to the traditional reflection law. The included angles formed by the lines are equal; the propagation direction of the component opposite to the incident circularly polariz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length b | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com