Air-cooled heat radiating module for high-power IGBT parallel connection

A heat dissipation module and high-power technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of reducing the life of the fan and system reliability, the deviation of the fan from the normal working area, and reducing the operating life of the fan, so as to achieve low loss , compact structure, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

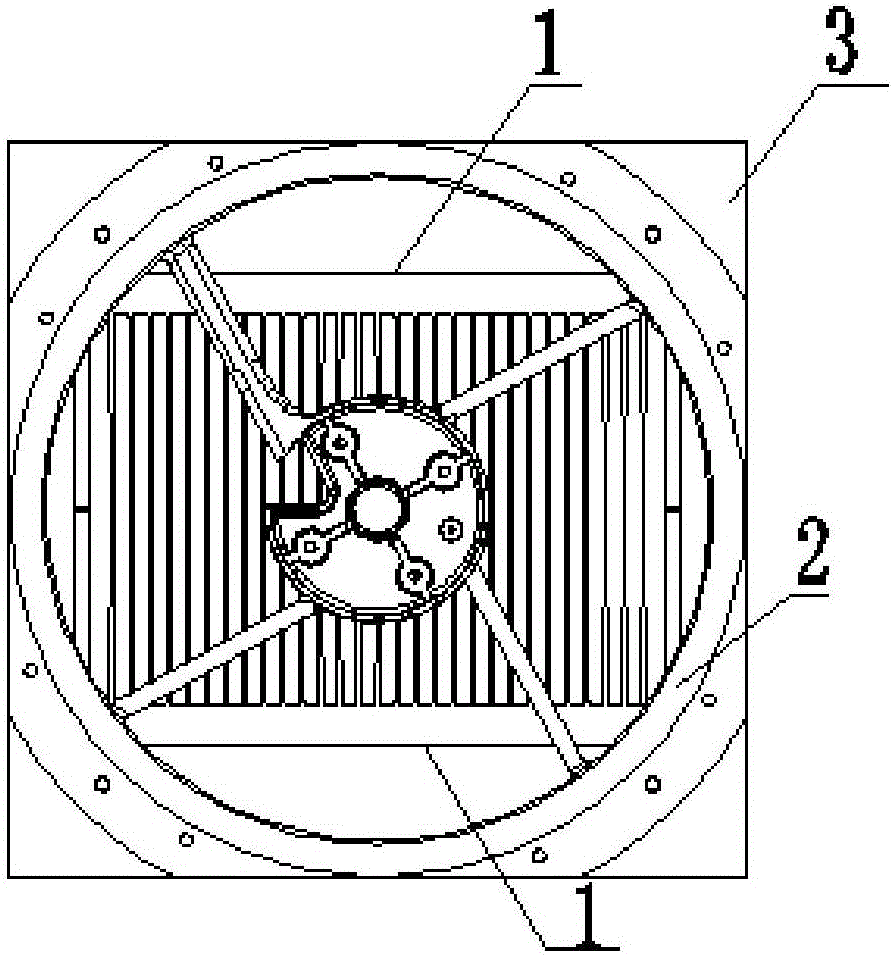

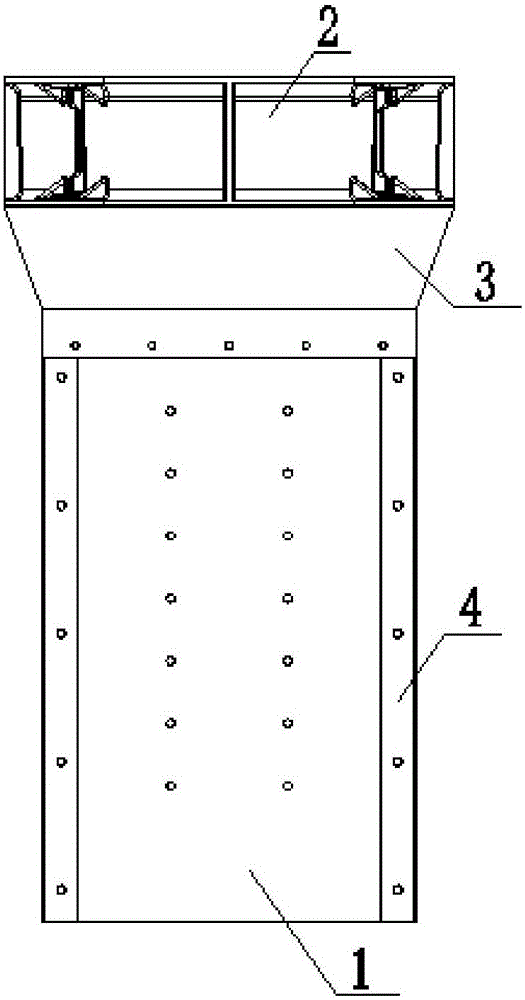

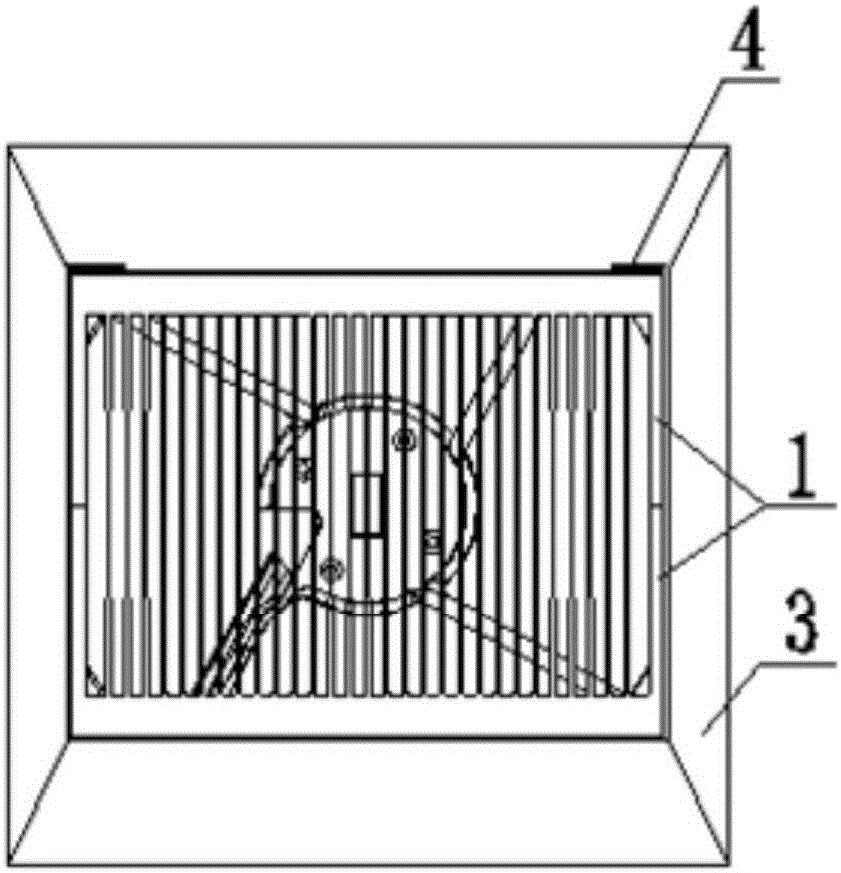

[0033] Such as Figure 1 to Figure 3 As shown, the present invention provides an air-cooled heat dissipation module for high-power IGBT parallel connection, including two identical heat sinks 1, a fan 2, a set of sealed air duct structure 3 and two sets of heat sink side seals The air duct structure 4 will be introduced separately below.

[0034] The outer contour of each heat sink 1 is a regular and uniform cylinder, and the radial cross-sectional size of the heat dissipation fins is consistent, and ordinary aluminum extruded heat sinks can be used, and heat pipe heat sinks can also be used to dissipate heat from the substrate; when installing, the two heat sinks Sheet 1 is installed in a mirror-symmetrical manner.

[0035] The two sets of heat sink side sealing air duct structure parts 4 respectively connect the sides of the two heat si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com