Ruthenium oxide-copper sulfide composite material, application thereof and electrode plate for supercapacitor

A composite material and copper sulfide technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of high price and limited application of ruthenium oxide, and achieve high cost, increase specific capacitance, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

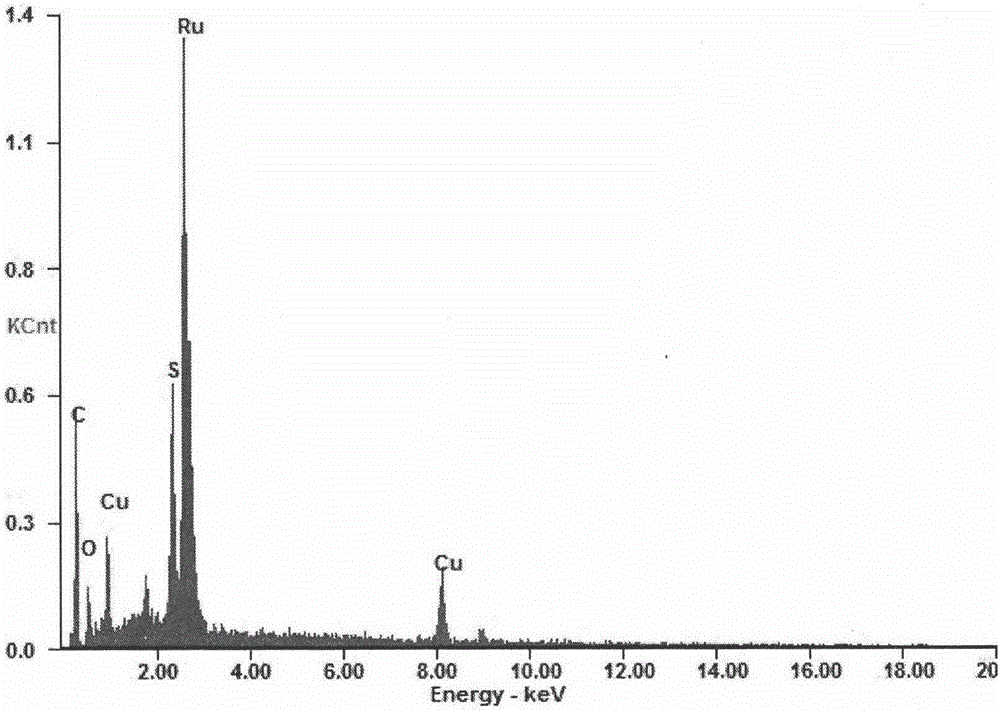

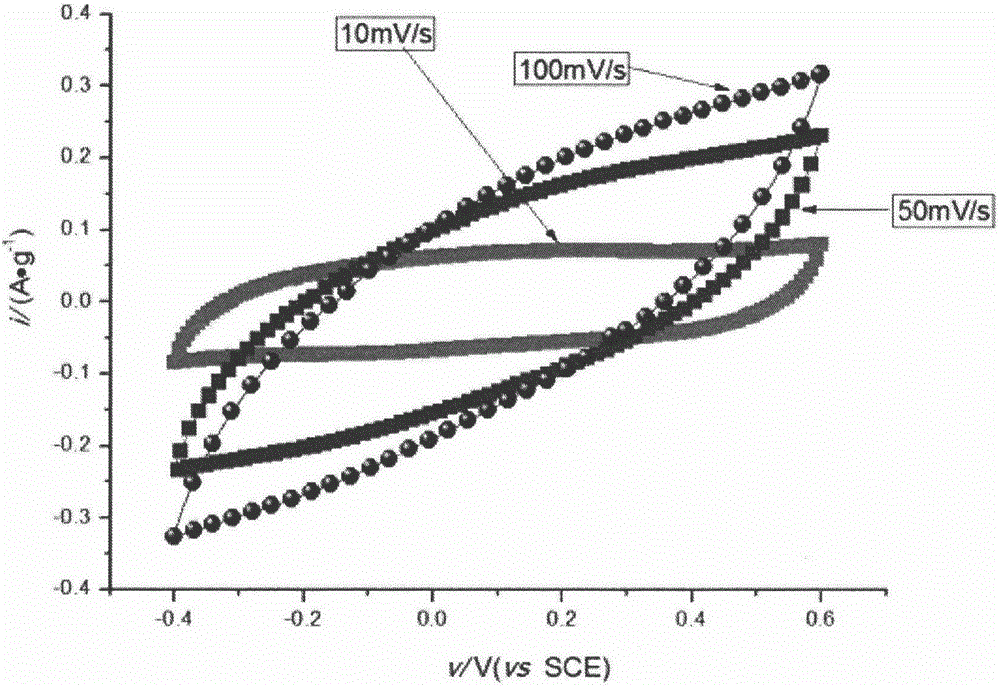

[0040] A ruthenium oxide-copper sulfide composite material, comprising 64% by weight of ruthenium oxide hydrate, 16% by weight of copper sulfide, 10% by weight of a conductive agent, and 10% by weight of 10% binder composition.

[0041] Its preparation method comprises the following steps

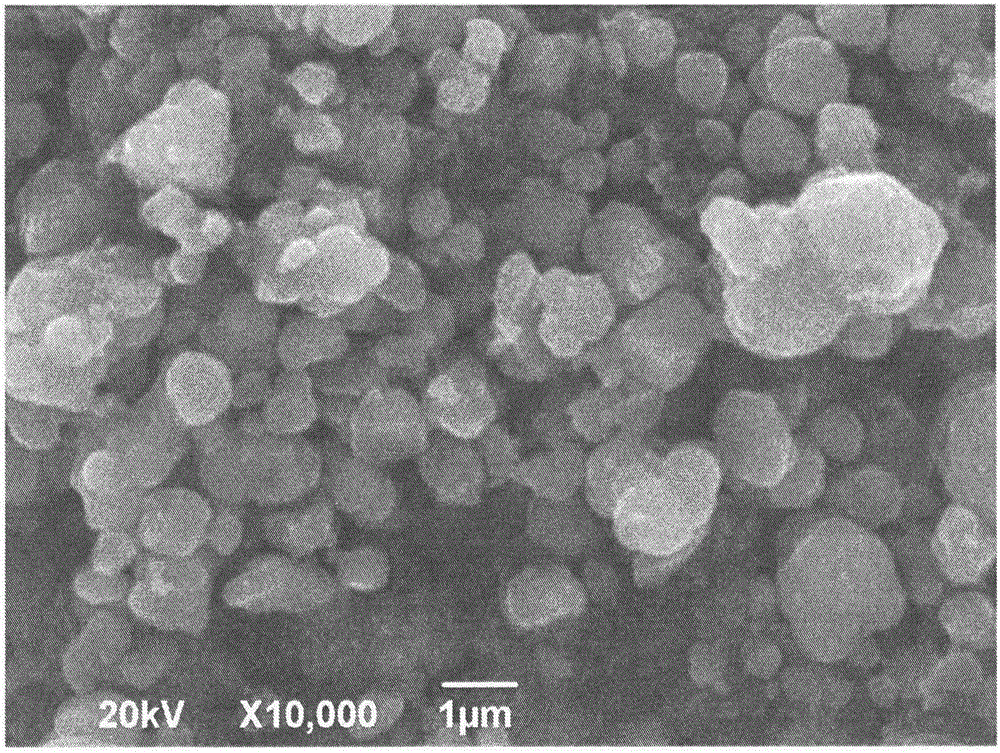

[0042] (1) Preparation of copper sulfide nanomaterials;

[0043] Ultrasonically dissolve copper chloride hydrate in ethylene glycol, then add thiourea to the above reaction system, and stir for 0.5h to 1h;

[0044] After the above stirring, after hydrothermal reaction at 150°C-200°C for 8h-12h, suction filtration, water washing, alcohol washing, and drying at 150°C-200°C for 24h, the copper sulfide nanomaterial is obtained;

[0045] (2) preparation of ruthenium trichloride solution;

[0046] Dissolving hydrated ruthenium trichloride in 40ml to 60ml of water to obtain a 10mg / ml to 20mg / ml ruthenium trichloride solution;

[0047] (3) Preparation of ruthenium oxide-copper sulfide composite...

Embodiment 2

[0054] A ruthenium oxide-copper sulfide composite material, comprising 56% by weight of ruthenium oxide hydrate, 24% by weight of copper sulfide, 10% by weight of a conductive agent, and 10% by weight of a conductive agent. 10% binder composition.

[0055] Its preparation method comprises the following steps

[0056] (1) Preparation of copper sulfide nanomaterials;

[0057] Ultrasonically dissolve copper chloride hydrate in ethylene glycol, then add thiourea to the above reaction system, and stir for 0.5h to 1h;

[0058] After the above stirring, after hydrothermal reaction at 150°C-200°C for 8h-12h, suction filtration, water washing, alcohol washing, and drying at 150°C-200°C for 24h, the copper sulfide nanomaterial is obtained;

[0059](2) preparation of ruthenium trichloride solution;

[0060] Dissolving hydrated ruthenium trichloride in 40ml to 60ml of water to obtain a 10mg / ml to 20mg / ml ruthenium trichloride solution;

[0061] (3) Preparation of ruthenium oxide-coppe...

Embodiment 3

[0068] A ruthenium oxide-copper sulfide composite material is composed of 50% by weight of hydrated ruthenium oxide, 32% by weight of copper sulfide, 10% by weight of a conductive agent, and 10% by weight of a conductive agent. 8% binder composition.

[0069] Its preparation method comprises the following steps

[0070] (1) Preparation of copper sulfide nanomaterials;

[0071] Ultrasonically dissolve copper chloride hydrate in ethylene glycol, then add thiourea to the above reaction system, and stir for 0.5h to 1h;

[0072] After the above stirring, after hydrothermal reaction at 150°C-200°C for 8h-12h, suction filtration, water washing, alcohol washing, and drying at 150°C-200°C for 24h, the copper sulfide nanomaterial is obtained;

[0073] (2) preparation of ruthenium trichloride solution;

[0074] Dissolving hydrated ruthenium trichloride in 40ml-60ml water to obtain 10mg / m1-20mg / ml ruthenium trichloride solution;

[0075] (3) Preparation of ruthenium oxide-copper sulfi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com